Novel Silicone Surfactants for Waterborne Wood Coatings

Excellent Performance at Highest Application Speeds

Aqueous coating systems not only play a key role in the reduction of volatile organic components in DIY applications, they are also becoming increasingly important to industrial coating processes as an alternative to classic solvent-based coating systems. In the context of industrial wood coating applications, current estimates indicate that ~40% of the produced coating volume in North America comprises aqueous coating systems – and this ratio is rising significantly. Alongside physically drying one-component systems, aqueous two-component polyurethane and radiation-curable systems are increasing in use. The formulation of such aqueous wood coating systems can at times seem very challenging, since wood, as a natural, porous and absorbent substrate, can place considerable demands on the formulator, especially in terms of substrate wetting and leveling. The varied use of aqueous wood coating systems, particularly in the building products, furniture and hardwood flooring industries, has resulted in very differing application methods (e.g. spraying, rolling, vacuum or curtain application). Additionally, the effects of these higher shear application systems can present major challenges with regard to foam stabilization within these aqueous coating systems. The high polarity and surface tension of water makes it necessary to use specific surface additives, so-called silicone surfactants, to ensure a sufficient wetting of the wood surfaces by the aqueous coating systems. Conventional silicone surfactants are characterized, in part, by a very strong reduction in the static surface tension, resulting in a highly effective substrate wetting. However, they have restrictions in terms of improving leveling, and at times have a tendency to stabilize foam during coating production and application. This article presents a class of new silicone surfactants that offer sufficiently good substrate wetting, with considerably improved leveling properties and only a slight tendency to stabilize foam.

Structural Features: Silicone Surfactants in Comparison

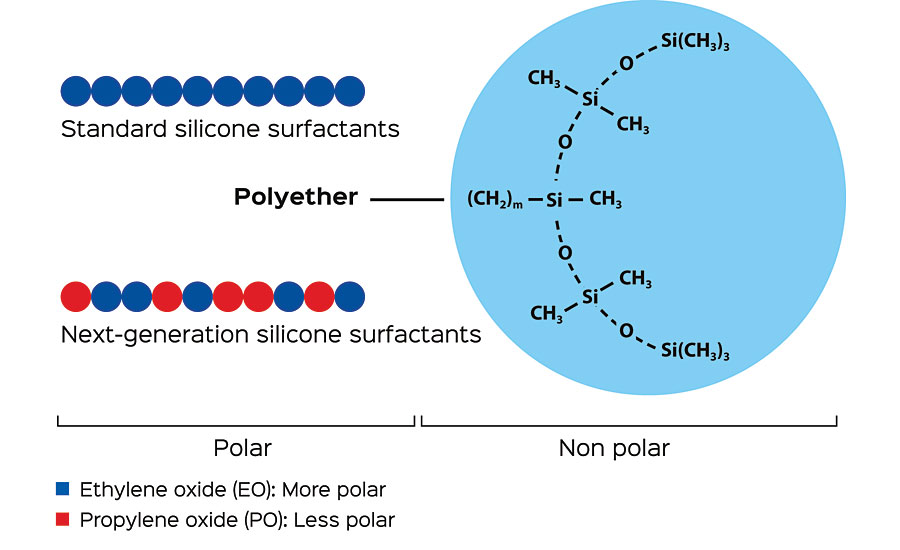

The silicone surfactants used in aqueous coatings nowadays are “organically modified polysiloxanes” that consist of a short hydrophobic silicone backbone modified with pendant hydrophilic groups. In the majority of cases, the modification involves polyether chains (Figure 1), which lead to an improvement in compatibility. The degree of compatibility can be controlled by the number of these side chains (i.e. ratio of dimethylsiloxane units to polyether modifications). At the same time, this also influences the surface tension: generally speaking, the more dimethylsiloxane (SiO(CH)) units, the lower the surface tension.

Furthermore, the structure of the polyether chains themselves can also be varied; the key factor here is the polarity. Polyethers consist of ethylene oxide units (EO) and/or propylene oxide units (PO). EO is very hydrophilic (polar), whereas PO by comparison, is rather hydrophobic (non-polar).

Standard silicone surfactants bear pendant polyether chains containing only EO units that are used to achieve good aqueous solubility. By contrast, the new silicone surfactants have modified, more amphiphilic polyether chains. Alongside EO units, PO units are also used. Their adjustable ratio and arrangement in the polyether chains bring about an enhanced range of properties, and the polarity of the entire silicone additive can be controlled via the EO/PO ratio. A greater proportion of EO increases the polarity, and the additive is more water-soluble and more compatible in polar coating systems. At the same time, however, the tendency toward foam stabilization increases. On the other hand, a greater proportion of PO reduces both the water solubility and foaming tendency. Unlike standard silicone surfactants, these new silicone surfactants are characterized by their targeted orientation not only at the coating/substrate interface (= improved substrate wetting) but also at the coating/air interface (= positive influence on the coating leveling). Due to their controlled, reduced system compatibility, they also have a significantly reduced tendency to stabilize foam within coating production and application.

Silicone Surfactants in an Application Technology Comparison

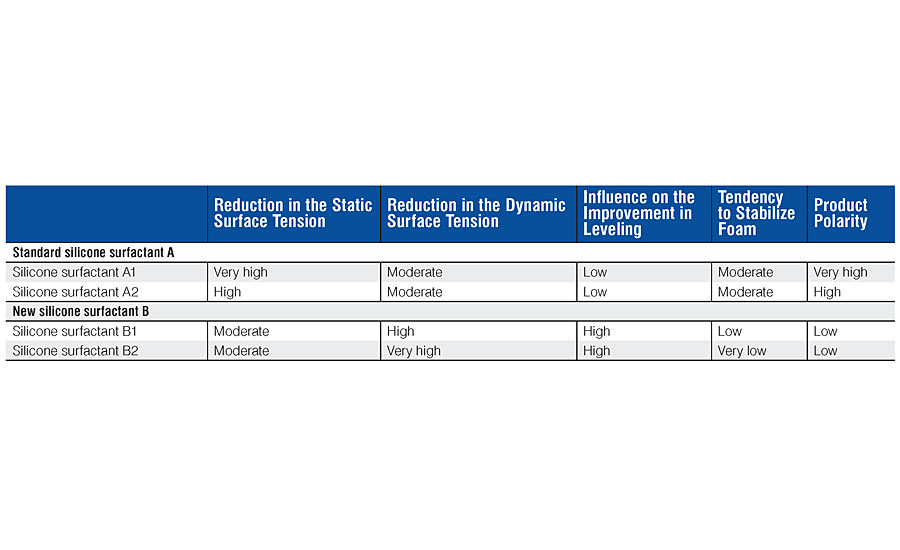

As part of an application technology study, the silicone surfactants A1, A2, B1 and B2 listed in Table 1 were compared with one another. For this purpose, these four surface additives were added to a variety of representative, aqueous wood coating systems in differing dosages, and their influence on the static surface tension, the improvement in leveling of the coating, and the tendency to stabilize foam within the coating application were tested.

Impact on Static and Dynamic Surface tension

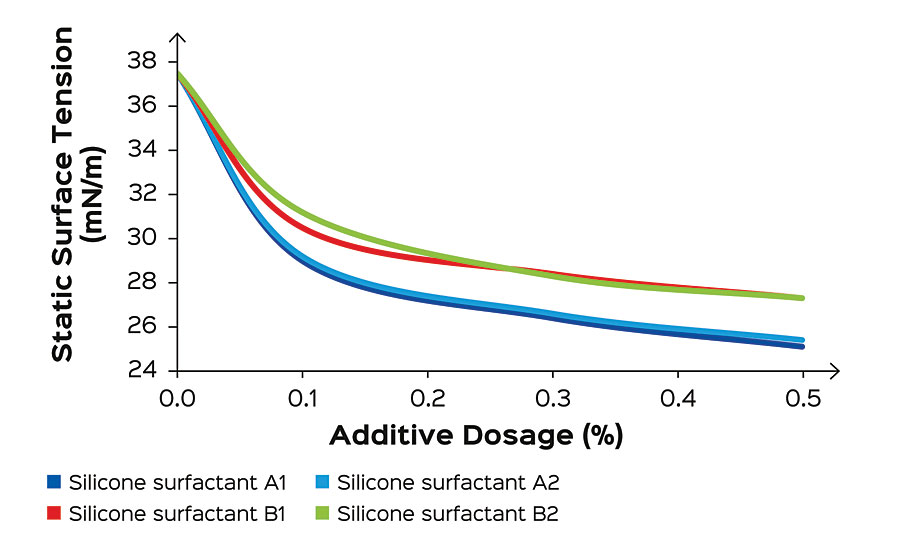

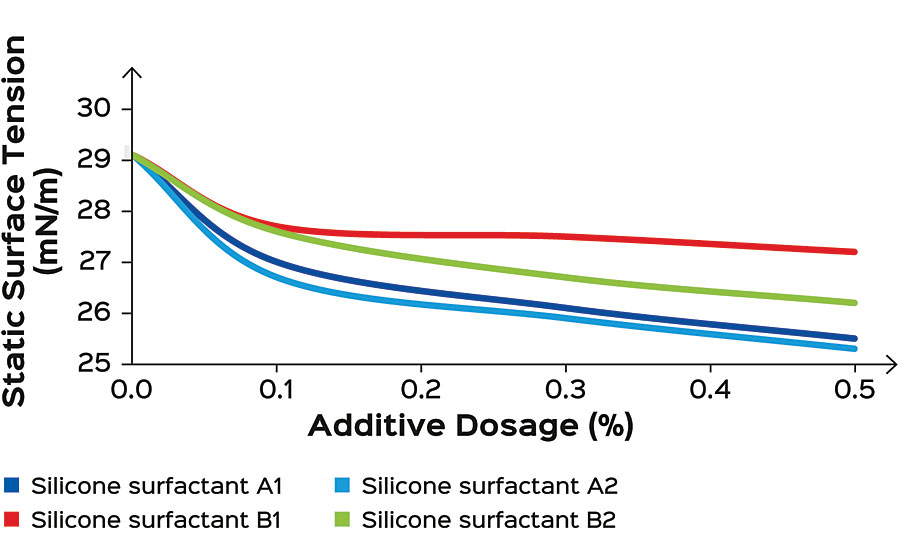

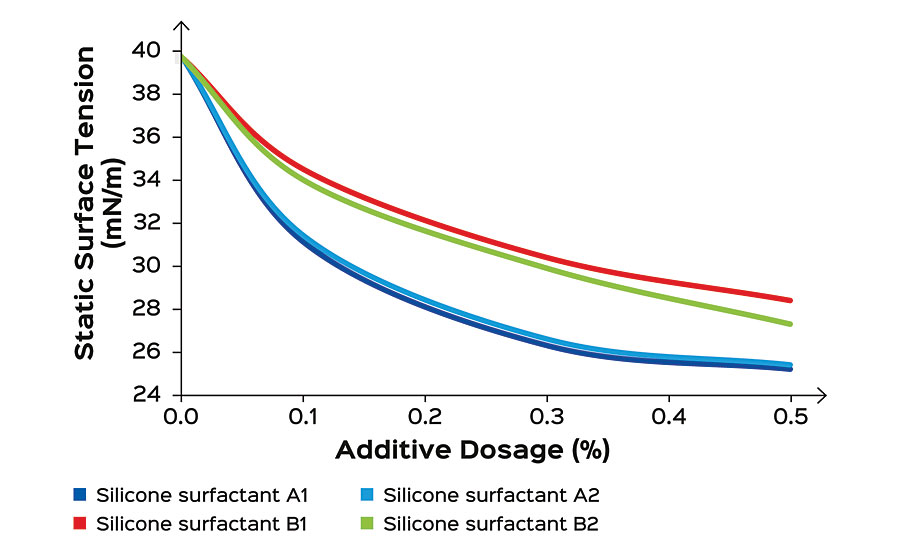

In the first step of the application technology study, these four different silicone surfactants were tested in different aqueous wood coating systems with regard to the influence on the static surface tension. For this purpose, the products that were to be compared were added to the various coating systems in three different dosages (0.1%, 0.3% and 0.5% based on the total formation), and their impact on the static surface tension was established using the Du Noüy ring method.

Figure 2, figure 3 and figure 4 illustrate, irrespective of the tested aqueous wood coating system, that the standard silicone surfactants A1 and A2 result in a partially considerably stronger reduction in the static surface tension than the two new silicone surfactants B1 and B2. At first glance, it would appear there is a clear technical advantage with the standard silicone surfactants. However, if we consider that the surface energy of classic wood substrates such as beech (59 mN/m), oak (49 mN/m), pine (46 mN/m), Douglas fir (39 mN/m) and even teak (30 mN/m) is generally greater than 30 mN/m, the two tested new silicone surfactants provide exactly the correct degree of reduction in the static surface tension to enable a sufficient substrate wetting but also to avoid the undesirable side effects, such as leveling problems or foam stabilization. In addition to their precisely tailored degree of reduction in the static surface tension, the two tested new silicone surfactants offer a very efficient reduction in the dynamic surface tension that is much more pronounced compared to conventional silicone surfactants. As a result, the silicone surfactants B1 and B2 contribute to significantly enhanced surface leveling and least foam stabilization tendency in particular for demanding high-speed application processes like roller or spray application.

Leveling Improvement in Comparison

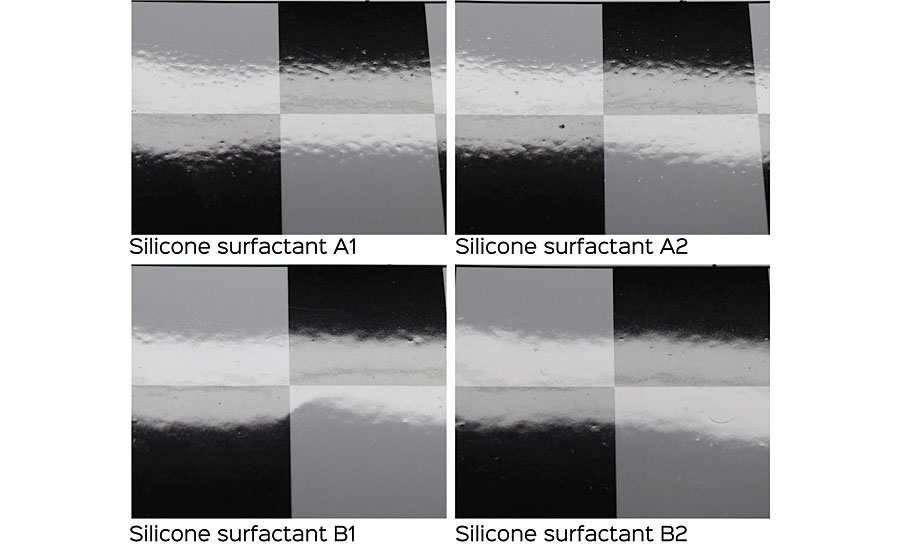

In sharp contrast to undesirable leveling problems, the new silicone surfactants in fact contribute to an improved leveling of the coating surface. Figure 5 records in a photo protocol the influence of the different silicone surfactants on the leveling of an aqueous, physically drying wood coating based on a pure acrylate dispersion. The silicone surfactants A1, A2, B1 and B2 were added to the test system with (in each case) a dosage of 0.3% based on the total formulation. They were then applied to a contrast board using a fine-pored moltoprene roller. After the physical drying, they were visually assessed in terms of leveling. The reflecting light source in the coating surface makes a considerable difference to the leveling of the coating when using the silicone surfactants A1 and A2 and the silicone surfactants B1 and B2.

Tendency to Stabilize Foam During the Coating Application

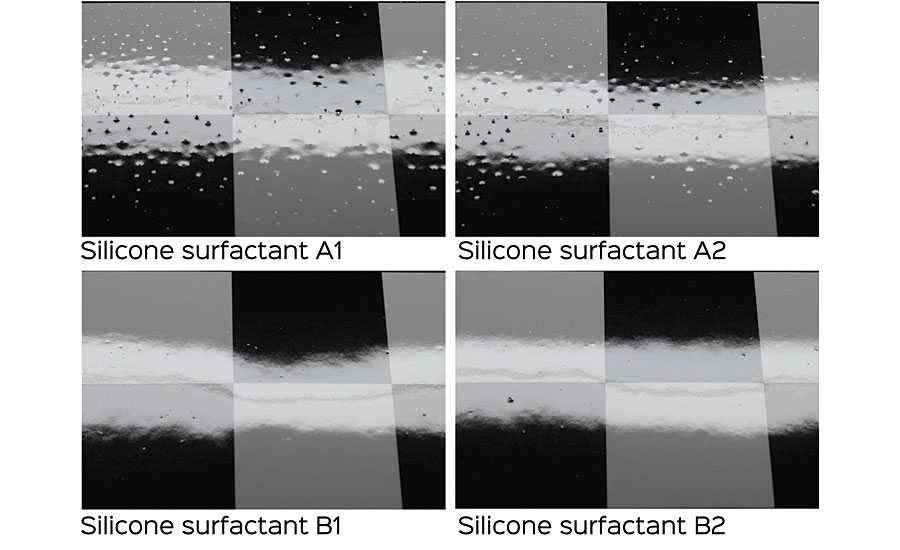

A considerable difference was established for some of the aqueous wood coating systems in terms of the tendency of the various silicone surfactants to stabilize foam. Figure 6 makes this difference very clear. In this case, the silicone surfactants A1, A2, B1 and B2 were added with (in each case) a dosage of 0.3% of an aqueous radiation-curable wood coating based on a urethane dispersion. They were then applied to a contrast board using a fine-pored moltoprene roller. After the physical and subsequent radiation-curing drying, they were visually assessed in terms of their tendency to stabilize foam. The photographic comparison of the four samples shows very clearly that the tendency to stabilize foam of the two new silicone surfactants B1 and B2 is considerably lower than that of the two standard silicone surfactants A1 and A2.

Conclusion

The new silicone surfactants B1 and B2 represent a tailor-made additive solution for aqueous, industrial wood coatings. Their fine balance between pronounced surface activity and controlled reduced compatibility in aqueous wood coatings provides an optimum range of properties consisting of sufficient reduction in the static surface tension, pronounced reduction in the dynamic surface tension, leveling improvement and only a minor tendency to stabilize foam during coating production and application. The new silicone surfactants are ideal for broad application in physically drying one-component systems, two-component polyurethane systems and radiation-curable systems, and, in a multitude of application technology tests, have shown a superior efficiency compared to standard silicone surfactants.

Results at a Glance

• New silicone surfactants for aqueous industrial wood coating systems illustrate various technical advantages compared to standard silicone surfactants.

• They provide a sufficiently strong reduction in the static surface tension, which leads to an effective substrate wetting of aqueous coating systems on a wide range of wood substrates

• In addition, the new silicone surfactants contribute towards a considerable improvement in the leveling properties, and tend not to stabilize foam within the coating production and application.

• Due to their tailored system compatibility, the new silicone surfactants are suitable for use in both aqueous one-component systems as well as in aqueous two-component polyurethane and radiation-curable systems.

Acknowledgments

The author would like to thank Margret Gilsbach and Carsten Erkens for performing the application tests and proving the technical results, as well as Dr. Guillaume Jaunky for his valuable discussions and the revision of the article.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!