Changing Monomer Feed Rates in A Semi-Batch Emulsion Polymerization Can Affect Your Product Properties

Did you know… that changing the rate of monomer addition in a semi-batch emulsion polymerization can affect your product properties? Monomer feed rates may be varied for different reasons. Increasing monomer feed rates can reduce the overall batch cycle time and increase productivity. If you are making core-shell or other structured particles, controlling monomer feed rates is an important strategy for obtaining the desired morphology.

However key polymer particle properties, including molecular weight, degree of branching and extent of crosslinking, are influenced by the monomer concentration inside the particles, which in turn is largely determined by the rate at which monomers are fed, coupled with reaction temperature. Higher monomer concentrations result in longer polymer chains (higher molecular weight) being made at any instant during the polymerization. Conversely, lower monomer concentrations result in shorter polymer chains (lower molecular weight) being made at any instant. However lower monomer concentrations can also increase the rates of branching and crosslinking.

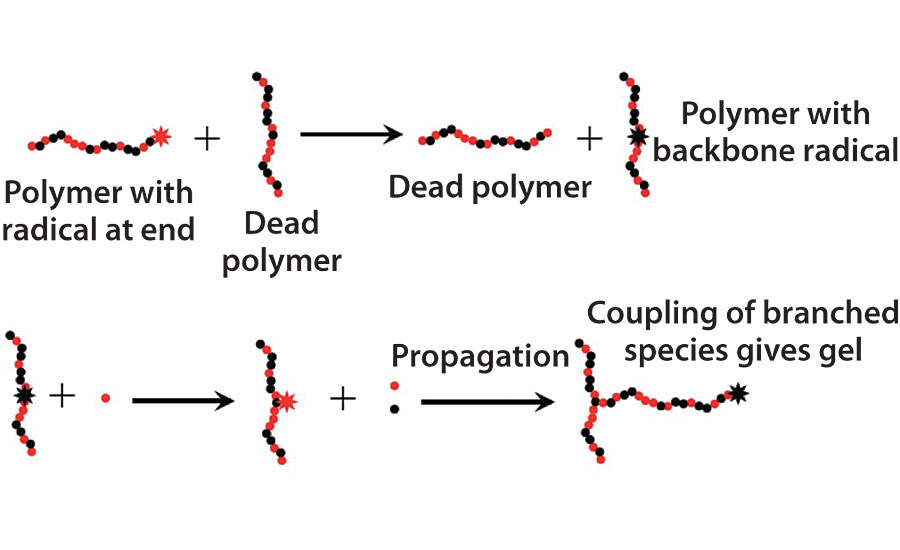

The rate of radical chain transfer to polymer is proportional to polymer concentration; at high polymer concentrations (i.e. low monomer levels), chain transfer to polymer and therefore branching increases. If the propagating, branched polymer chains terminate by combination (versus disproportionation), then crosslinking can occur (Figure 1). Monomers that inherently have high rates of chain transfer to their polymers, including for example acrylates and vinyl acetate, are particularly susceptible to this behavior.

The takeaway lesson is that whatever your reasons for varying the monomer feed rates, be aware that there may be unintended effects; in addition to the desired outcome, some product properties may also change.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!