Metal Matrix Composites - The Complete Solution

In the defense against the war on corrosion and wear, maintenance repair engineers will be hard pressed to find a plating material as strong as chrome. Ideal for high-friction environments, hard chrome is one of the most commonly used plating materials due to its increased erosion resistance, surface hardness and durability.

Leaving a smooth and shiny finish, this blue-white lustrous metal has been used in a variety of industries, such as aerospace engineering, marine and automotive. Along with its durability, hard chrome comes with a plethora of benefits thanks to its lubricity, versatility, wear resistance and adherence. However, there is increasing pressure to find an alternative to this material due to the worker safety and environmental issues it presents.

Chromium - a Human Carcinogen

While hard chrome isn’t toxic in its finish state, it poses a risk to technicians when it is in its hexavalent state (known as chromium(VI), chromium 6, Cr(VI) or Cr6+). This is because it has carcinogenic and teratogenic properties, which has toxic and mutagenic effects on microorganisms and cells. Airborne Cr6+ has been linked to lung cancer and causes damage to the nose, throat, and lungs when inhaled or consumed.

Hexavalent Chromium - Causing Occupational Cancer

It’s thought that 558,000 U.S. technicians are exposed to airborne Cr6+ in the workplace every year.1 Employees working in the electroplating, welding and painting industries are most at risk, as they are exposed to high levels of Cr6+ compounds.

This is even more the case for workers who handle Cr6+ pigment coatings and operate plating baths, as they are responsible for its storage and disposal. If hexavalent chromium is improperly stored or disposed of, it poses risks to both the technicians working with it, the general public, and the environment.

The Leak on 1-696

In 2019, a liquid solution containing green hexavalent chromium and cyanide made its way onto the I-696 highway in Madison Heights, Michigan, after an electroplating factory had failed to properly dispose of more than 37,000 gallons of hazardous waste they had produced over the past 20 years. This put countless lives at risk, and the Environmental Protection Agency spent $1.5 million cleaning up the source of the pollution.

The Decimation of Xiaoxin Village

The improper disposal of chromium isn’t just a problem in the U.S., but in China as well. In 2011, it was revealed that more than 5,000 tonnes of toxic chromium tailings were dumped near a Yunnan reservoir in China.

Livestock died, crops were destroyed and their water turned yellow. An investigation found that a pond upstream of the reservoir had hexavalent chromium readings 2,000 times above normal levels. While this problem was discovered in 2011, 37 villagers have since died of various forms of cancer since 20062 and are suspected of being attributed to the chromium tailings.

A Call for a Safer Alternative

In September 2017, Cr6+ was banned in Europe, under Europe’s Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations, after it was found to be the root cause for 300 lung-cancer related deaths a year.2 However, Cr6+ is still being used in North America.

The CDC (Center for Disease Control) and OSHA (Occupational Safety and Health Administration) have taken measures to protect employees from hexavalent chromium exposure, but more and more industries across the globe are calling for a safer alternative - one reason being the challenge in disposing of these chemicals safely.

A Solution for Electroplaters

One solution that’s leading the way is brush-plated metal matrix composites (MMC). Chromium in this form does not exhibit the same safety hazards as hexavalent chromium because it is contained in the solid particles. This new generation of coating doesn’t require the use of tanks and is much safer for both people and the environment.

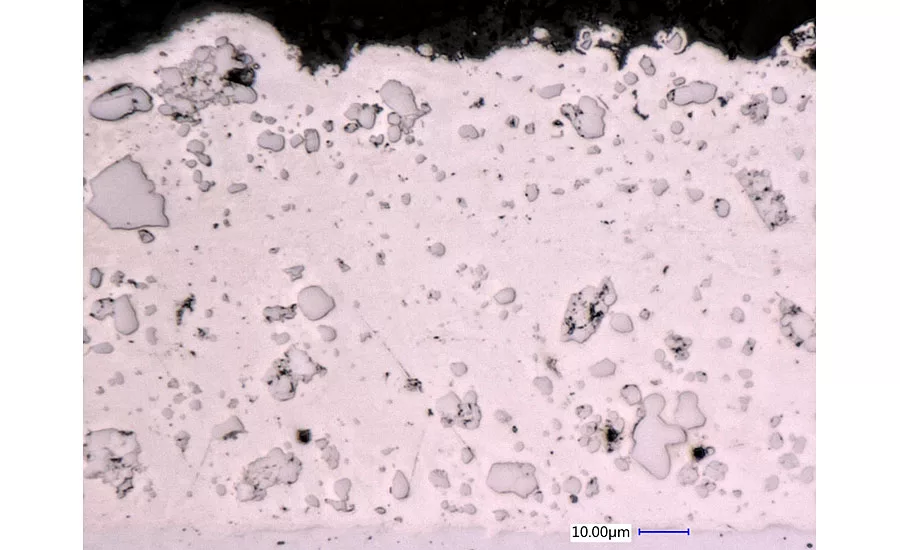

Made up of cobalt and chromium carbide, nickel tungsten and chromium carbide, or nickel and chromium carbide, these coatings are improved by the co-deposition of the nonmetallic carbide particles. The particles become embedded in the metal matrix as it is deposited using a range of current densities and brush materials. When the size and concentration of the particles are carefully selected, engineers are able to tailor the plating process to suit each individual component, as they can fine-tune the deposit for wear resistance, high-temperature performance or mechanical strength. With a low coefficient of friction, high heat conduction, durability and more, MMC is an excellent match for hard chromium.

Brushing Up on the Process

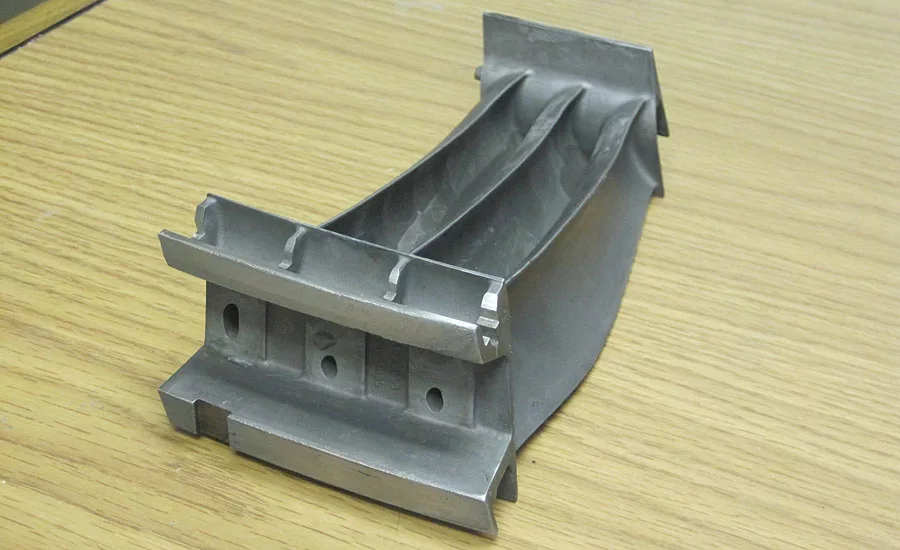

As well as matching hard chrome’s properties, brush plated MMC is also much more efficient to apply. When a component undergoes hard chrome plating in a tank, it must be disassembled, the piece is transported to the plating plant, masked, and placed into a tank filled with a chromium plating solution. Once the component has been plated, it is shipped back and reassembled.

In contrast, brush plating with an MMC solution such as SIFCO ASC’s Aeroshield® is portable and can be used almost anywhere, but it can also be mechanized or automated for minimal operator intervention. Whether it’s in the shop, or out in the field, downtime is reduced as by masking off only the specific area needing protection or repair, reducing the need to disassemble the machine or transport the parts.

Brushing Up on Sustainability

Another key benefit of brush plated MMC is that it uses very small volumes of solutions in comparison to tank plating. Whereas hundreds of gallons of solution is required to fill up a tank, a brush plating system can use as little as one liter of solution depending on the size and thickness requirement of the area. This not only saves on space and helps reduce waste but brings down the costs of waste disposal. Storage space is also freed up as there’s no need to store excess chemicals.

While brush and tank plating both require proper ventilation and personal protective equipment, when plating with chrome, OSHA states employers must, “limit eight-hour time-weighted average hexavalent chromium exposure in the workplace to 5 micrograms or less per cubic meter of air.” This becomes even more complicated as the solution in the tank will heat up and cool down, which is out of the operator’s control. All of these puts workers at risk and makes the process even longer.

However, depending on the size of the area and thickness required, an MMC brush plating operation only lasts approximately one hour from start to finish. And since Cr6+ is not an inherent property of the deposit, the environmental and health risk is greatly reduced.

MMC brush plating is a method of electroplating that offers a high degree of flexibility, and creates a safer, healthier working environment. Whether for OEM or repair applications, the portability, ease of use, and the minimal solutions required make brush plating an attractive option to consider.

Find out more about SIFCO ASC’s brush plating solutions at www.sifcoasc.com.

References

[1] https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4756268/

2 https://www.chemicals-technology.com/news/chromium-vi-regulatory-approval-europe/]

By SIFCO Applied Surface Concepts

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!