New Nanocoating Improves Surface Cleaning and Disinfecting

The coronavirus has had a devastating social and economic impact on modern society. Currently, there is no cure, and it will be months before a proven vaccine is developed. Since the coronavirus is highly infectious and easily transmitted between humans, surface cleaning has gained a critical new importance to control its spread.

Medical facilities are designed to manage germ and bacteria growth in a number of ways. Materials such as glass, stainless steel and high-density plastics are used for fixtures and equipment. Special paints formulated for continuous cleaning and disinfecting are applied to all interior walls. In recent years, antimicrobial coatings have gained acceptance for medical facilities and homes where individuals have health problems such as asthma. These coatings are formulated with additives including silver, copper and ammonium to kill germs.

Continuous cleaning reduces patient and worker exposure to disease, but it actually damages surfaces due to physical abrasion and chemical interaction. This increases the potential for additional soiling and presents difficulty for future cleaning operations.

Modern cleaning is based on the following steps:

- A cleaning material is applied to a soiled surface.

- Available contaminants are placed in suspension.

- Germs and microbes are killed by specific cleaning formulations.

- The cleaner/soil/germ combination is wiped or rinsed clean.

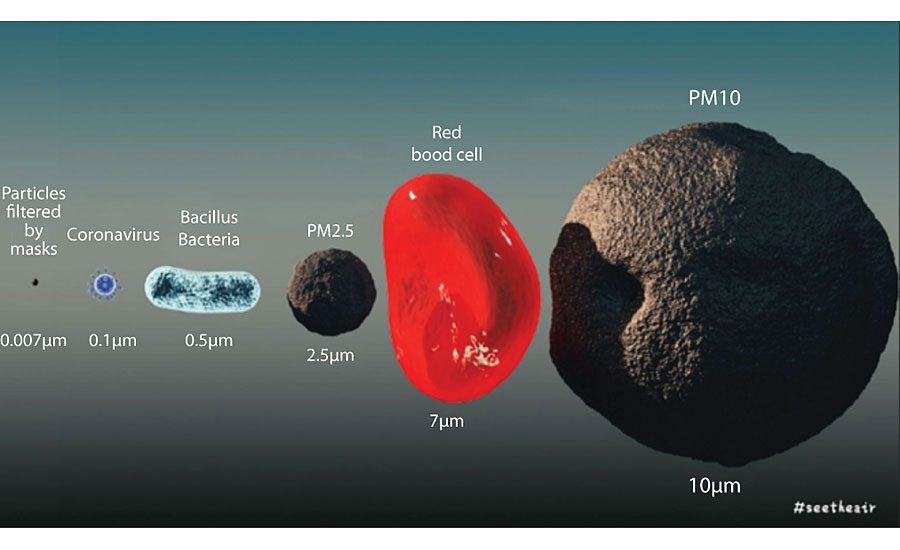

Cleaning performance is verified by workers using visual inspection, which may not be effective due to the microscopic size of the coronavirus and other microbes (Figure 1).

A Nanosolution

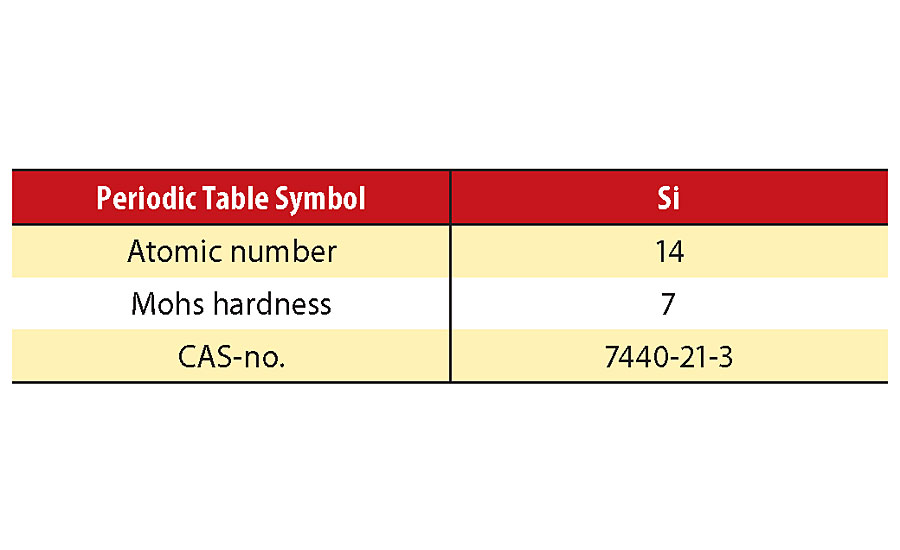

Nano-clean is an engineered program designed to solve the limitations of traditional cleaning practices. Nano-clean is based on the science of nanotechnology – the creation or organization of materials, devices or systems at the nano level (1 billionth of a meter). The main component of Nano-clean is silicium, also known as silicon, a component of glass and the same material used to produce modern computer chips (Table 1). Cleaning performance is improved by the modification of surfaces at the microscopic level. This creates a surface similar to hardened glass. When silicium is incorporated in a micro-molecular polymer, it is transformed into a highly effective, ultra-thin protective coating suitable for any hard surface.

Traditional coatings contain a resin/binder, pigments, additives and a solvent- or water-based carrier. Pigments provide color, and improve chemical and abrasion resistance. The resin/binder is the glue that holds the pigments and additives in suspension. The solvent- or water-based carrier aids in film formation and evaporates away during the cure cycle. Adhesion is the result of mechanical and chemical interaction between the coating and the applied surface.

Nano-clean has no color pigments or resin/binders, only silicium nanoparticles. It is bonded to the surface by electrostatic attraction. This effect is produced by the positive charge of silicium nanoparticles and the negative charge of the host surface. No reaction time is required. As soon as silicium comes in contact with the base material the cure process is complete. Performance is maintained by re-application. Re-application is cost effective because the initial application provides the foundation for later recoating. This dramatically reduces labor and material expense.

How It Works

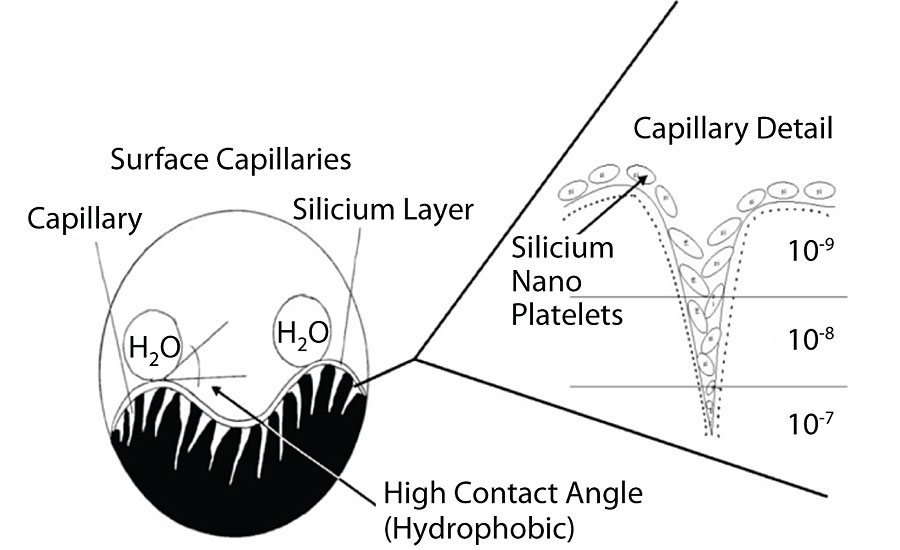

Virtually all natural and manufactured surfaces contain microscopic defects known as capillary structures. Under magnification these irregularities appear like the peaks and valleys of a mountain range. Dust, dirt and chemical residue are absorbed into these voids where they are extremely hard to remove. Capillary structures also provide microbes with an excellent place to grow and multiply. Figure 2 is an illustration of a capillary structure.

Silicium nanoparticles fill the capillary cavity with positively charged platelets that overlap each other like scales of a fish. This increases the barrier function of the nanocoating and prevents dirt, dust and microscopic microbes from entering the capillary void. Silicium is impermeable to moisture, which reduces the attraction for water-based contaminants.

Advantages

Nano-clean is not a cleaning product alone, but a component of a surface maintenance technology designed to establish and maintain a high level of cleanliness for surfaces exposed to infectious microbes. It provides a number of advantages:

- Airborne dust and dirt are repelled.

- Germ, bacteria and virus concentrations are significantly reduced.

- Water absorption and retention are eliminated.

- Labor costs are significantly lower.

- Reduces the need for aggressive and harmful cleaning products.

- Prevents microbes from finding an ideal breeding ground.

Reduced Cleaning Costs

Germs and bacteria can double in number every 20 minutes. This requires additional cleaning to keep microbe growth under control. This practice is expensive and unreasonable in the majority of cases. Nano-clean replaces cleaning in response to visible soiling with preventive maintenance where silicium is introduced as a proactive coating to improve performance and reduce overall cleaning costs. A 50% to 80% reduction in labor and material costs can be realized with Nano-clean.

Self Cleaning

Repeated use of Nano-clean produces a self-cleaning advantage by the van der Waals forces, which occur any time two surfaces are close together. The closer the contact points, the stronger the attraction. Since silicium nanoparticles strive to achieve a higher bonding level, contaminants are constantly being displaced for easy removal.

Water Break and Contact Angle Measurement

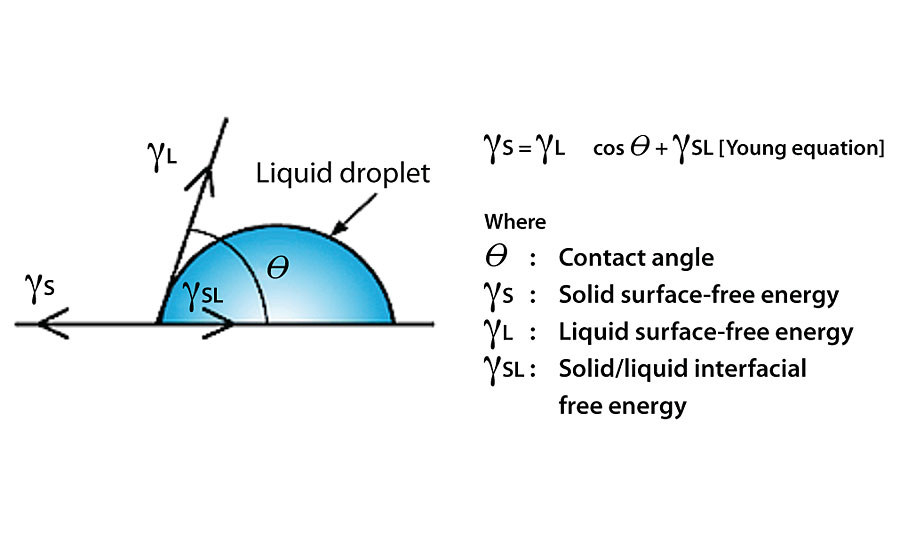

Nano-clean allows workers to monitor performance by ASTM F-22-02 water break testing by observing the way water beads up on a treated surface. Water droplets indicate the silicium coating remains intact (Figure 3). Nano-clean produces a hydrophobic surface, which repels moisture. In contrast, a hydrophilic surface absorbs moisture.

The level of water resistance is determined by the size and shape of the water droplets. This is measured by contact angle, which begins at the base of the water droplet and travels in a straight line to the break-off point (Figure 4). The higher the degree of the contact angle measurement, the more resistant the surface is to moisture absorption and retention.

Nano-clean is the first protective coating to use water break testing to monitor coverage and performance. Cleaning performance can also be checked by wiping a clean cotton cloth over treated surfaces. If drag resistance is detected this indicates the presence of excessive soiling.

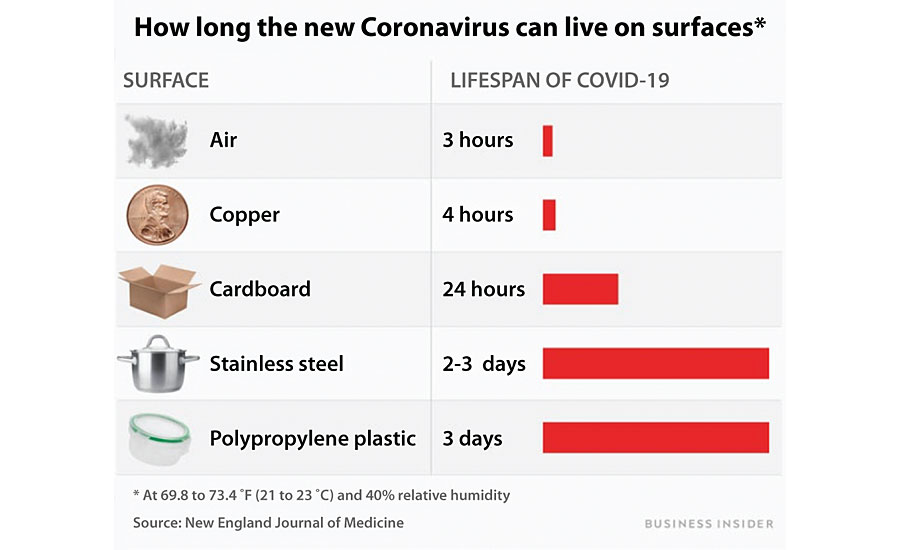

The removal of organic or inorganic contaminants depends on the type of surface involved. Smooth, hard surfaces are easier to clean than porous or irregular surfaces. Figure 5 shows the projected life span of the coronavirus on various surfaces.

Testing

Testing will be important for Nano-clean’s introduction to the market to demonstrate the advantages over traditional cleaning practices. Specific items to consider include:

- How silicium nanocoatings adhere to surfaces;

- How micro cracks and fissures harbor pathogens;

- How the viscosity of modern cleaners limit contact with submicron trenches;

- How surface condition affects cleaning performance;

- Why Nano-clean improves cleaning performance by sealing micro surface imperfections;

- How Nano-clean reduces negative environmental impact produced by traditional cleaning practices.

Performance testing for Nano-clean is fairly simple. It involves an untreated control coupon and a coupon treated with the silicium nanocoating. Water break testing is performed on each panel to demonstrate the differences for water absorption. Soiling of both panels with dirt, grime and bio-contaminants duplicates actual conditions.

The control coupon is cleaned using traditional cleaning practices and wiped down with a clean cotton rag. The Nano-clean-treated coupon is cleaned with soap and water, and wiped down with a micro-fiber cloth, which is designed to remove surface contaminants with microscopic hooks in the body of the cloth. Micro-fiber cloths improve cleaning by the removal of contaminants rather than just moving particles around. Performance differences are verified with a luminometer, an instrument used to measure microscopic concentrations

Conclusion

During the 20th Century there have been a number of pandemic attacks on the world’s population.

- The American polio epidemic of 1916: 27,000 cases, 6,000 deaths.

- The Spanish Flu from 1918 to 1920: 500 million cases, 100 million deaths.

- The Asian Flu from 1957 to 1958: 1.1 million deaths worldwide, 116,000 in the United States.

- The AIDS pandemic from 1981 to present: 35 million deaths worldwide.

- H1N1 Swine Flu pandemic from 2009 to 2010: 1.4 billion cases, 575,400 deaths.

- West African Ebola epidemic from 2014 to 2016: 28,600 cases, 11,325 deaths.

- One of the worst pandemics in history was the Black Death from 1346 to 1353: historians estimate it wiped out over half of Europe’s population.

In contrast, as of August 16, 2020 there were 5,370,000 cases of the Coronavirus in the United States, with 169,000 deaths and 2,904,440 recoveries. This represents a mortality rate of less than 4 percent.

There is little doubt there will be other infectious events in the future. Today the majority of surface cleaning and disinfecting is performed by reactive maintenance, defined as cleaning operations performed in response to excessive soiling, or preventive maintenance performed on a regular time schedule based on work histories or manufacturer recommendations. Nano-clean is a proactive maintenance program that considerers the optimum strategy to control the spread of infectious disease. The basic Nano-clean program can be used as a standard for other pandemic events where surface cleaning and sanitizing are important.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!