Saul’s Double Rub Debacle

Saul Vance counted to himself as he rubbed the coating panel, trying to keep his index finger at a 45-degree angle and not pushing too hard. After already running a previous test, he had to concentrate to keep track of the number of double rubs. The odor of the MEK (Methyl Ethyl Ketone) vapors coming off the saturated double thickness of cheesecloth he was pushing along the length of the metal panel didn’t help his concentration. He timed the back and forth movement of his arm with the metallic banging of the coil coating line accumulators moving up and down outside the small QC lab. The accumulators moved up as much as 80 feet to take up the slack in the coil line so that another coil coating panel could be cut from the line. Saul knew from the sound that the QC chemist was taking another sample from the line to test. As he stared at the coating break in the panel beneath his finger, he noticed sweat dripping from his forehead onto the panel, not from the heat, but from sheer terror. Now his coating formulation had failed twice to meet his own 200 double rub specification.

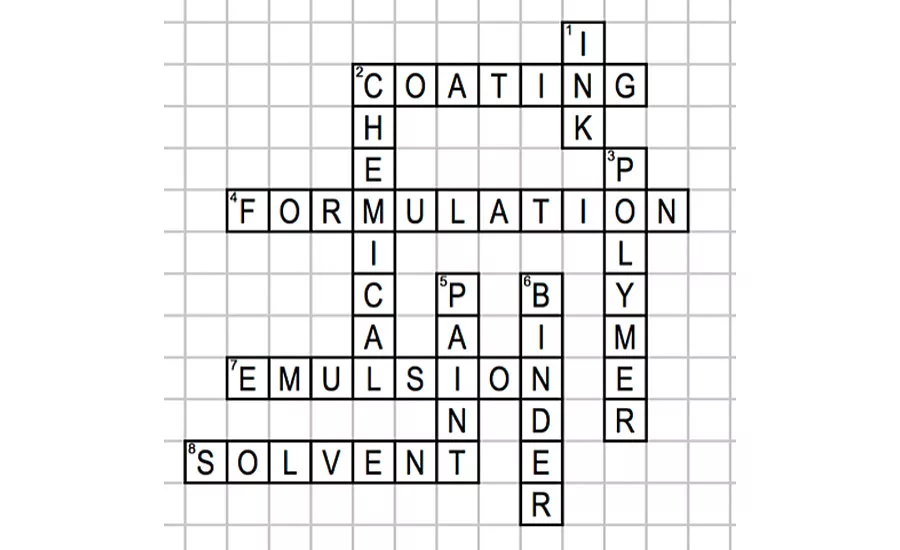

Saul’s coil line customers that purchased his coatings wanted to see how well the formulation resisted MEK solvent. Coil coating lines are highly mechanized and automated to give high-quality coated metal that can then be fabricated into parts for appliance, automotive and building products. This pre-painted metal process without overspray saves money because coil lines use close to 100% of the coating. The continuous process generates large quantities of coated metal in a short time. Over the years, the MEK double rub test had become a quick and easy way for coil coaters to determine the cure and crosslink density of the final baked coating. The solventborne formulations are applied and baked under controlled environments on the coil line. The cured coil coatings are tested on the line to meet tight specifications that ensure proper curing of the thermoset polyester formulations.

Earlier that morning the coil line QC chemist at Big Time Paint’s largest coil coater had called, his voice rising louder to be heard over the roaring of the coil coating line, and said, “Saul, we started up your formulation on line two. It looks good running at 500 feet a minute, but I am having trouble getting acceptable cure. You better get over here and show me how you got over 200 double rubs.”

As Saul Vance frantically drove the 55 miles from his office across town to his customer, he thought through all the possible pitfalls of the double rub test. Saul counted off the test conditions to check. Was the metal clean? Was the thickness correct? Did the coated coil reach peak metal temperature?

Saul realized that there is less variation in the coil coating line than the lab. The coil lines efficiently clean the metal before the coating is applied. The coil line can apply coating film thickness to within 0.1 mil or less. The temperature of the cure, which is a combination of peak metal temperature and dwell-time of the coating, is very consistently controlled. Low double rub numbers were not due to poor adhesion to the substrate, which can result in false-negative MEK double rub results. In the coil coating facility, his coating was being applied on a primer coat, applied immediately before. He knew that the most likely factor causing problems was the one he had control over and responsibility for…his formulation.

Coil lines emit very low VOC into the atmosphere because the gas-heated ovens use the solvent as fuel. Saul was reminded of this on his first trip to the coil line when he walked outside the yellow lines on the floor of the huge plant. The QC chemist told him that wandering outside of the yellow lines could be dangerous if the solvent got too high in concentration in the ovens. This could cause an explosion that, if strong enough, could blow out the huge metal walls of the ovens. The large walls of the oven were mounted on sliding blow out panels that released the energy of the igniting solvent in a “nondestructive event,” knocking anything between the walls and the lines on the floors with a force of a speeding truck. Saul never changed the solvents in the formulations that were matched to the fuel load required for each coil line.

Now in the QC lab, Saul waited for the QC chemist to return with the third panel to test. He looked at the first two panels in disbelief. Neither had reached even 100 MEK double rubs before removing the coating. His formulation wasn’t performing the way he had guaranteed it should.

Saul was never a big fan of the MEK double rub test procedure outlined in ASTM D5402-15. The test outlined two slightly different methods, a standard method and one used by coil coaters. The coil coaters’ method specifies a finger pressure of between 2,000 and 3,000 g of force. He didn’t have confidence that he could maintain this level of force from his index finger pushing on the panel. The method stated, “If multiple specimens are being tested and fatigue sets in, making it difficult to maintain the 2,000 to 3,000 g force, stop testing (after completing a specimen) until fatigue is gone.” Was he not pushing hard enough on the day he tested his coating in the lab? Was he pushing too hard now in the QC lab? He remembered thinking how stupid this test was, even though in his lab testing he had repeatedly generated over 200 MEK rubs.

When Saul verified another MEK double rub failure with the third panel, he worked up the courage to call his boss, Wyatt Walsh, back at Big Time Paint. He knew that there would be panic in the plant to get another coating batch to the coil producer. After Saul confirmed the out-of-spec double rub testing, Wyatt said, “Saul, I forgot to tell you before you left this morning that our customer had requested a change in the formulation. They wanted to replace the fluorosurfactant with an acrylic flow control agent. Their European customers are concerned about PFOA and PFOS levels, and wanted to go with a non-fluorinated additive.”

Saul breathed a sigh of relief when he realized the customer had changed the formulation. He couldn’t be held responsible if the customer changed his formulation. Right when Saul began to relax, Wyatt added, “The change is why you had a problem passing the MEK double rub test, but you aren’t off the hook for this debacle. You didn’t properly check the cure of your coating. When you do, you will find that you didn’t formulate the correct crosslink density. You better get back here and get to work solving this problem.”

Why did the change in the additive result in not getting the double rubs that Saul had gotten in the lab? Why was Saul still in hot water with Wyatt? How did Wyatt know that the formulation didn’t have correct crosslink density?

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!