What Coatings Manufacturers Need to Know About Autonomous Spray Robots

New technologies could change the way consumables are used and create new opportunities.

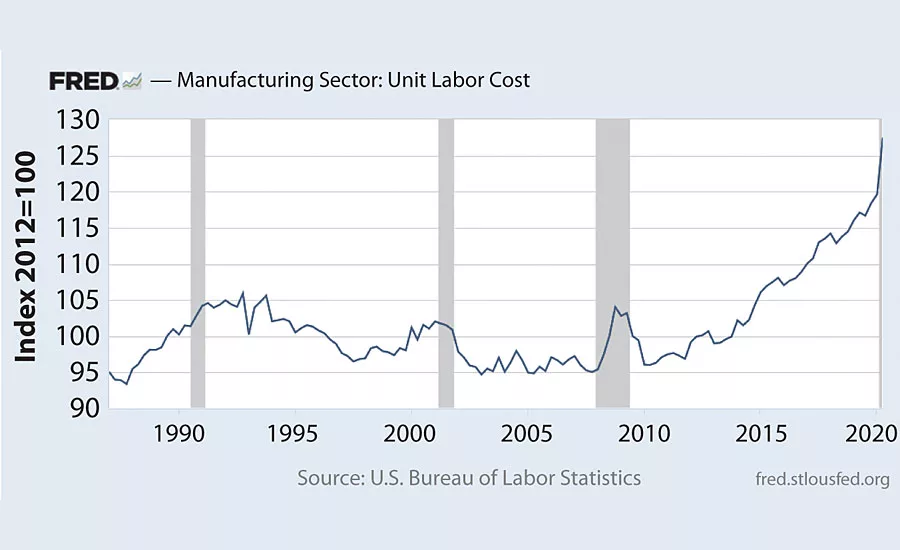

FIGURE 1: Statistics from the Fed show that underlying unit labor costs have been creeping to an unsustainable level for most American manufacturers, and coatings application is one of the chief causes of this.1

Coatings manufacturers have found steady income in the industrial coating space, but for many, a lack of investment and underlying challenges at applicator and client firms could be causing the industry to lag in growth when it need not. In these cases, many coaters have been faced with challenges like finding and retaining skilled labor, meeting demand without compromising quality, or simply maintaining high productivity and throughput without the need for constant rework.

In all of these cases, robotics offers the potential to enable these manufacturers to do more. But given that many of these firms are high-mix, most have not had any practical opportunity to use robots given the programming requirements and production constraints needed to properly process all the various parts that they handle.

In this case, self-programming robots present a game-changing opportunity for high-mix coaters to finally get the full benefits of automation. They promise to help ease the skilled labor shortage they face, while improving productivity, quality and profitability. At the same time, though self-programming can reduce waste, they also present the opportunity for coatings manufacturers to foster growth in the industrial coatings market by encouraging the use of such advanced application techniques.

What Is a Self-Programming Robot?

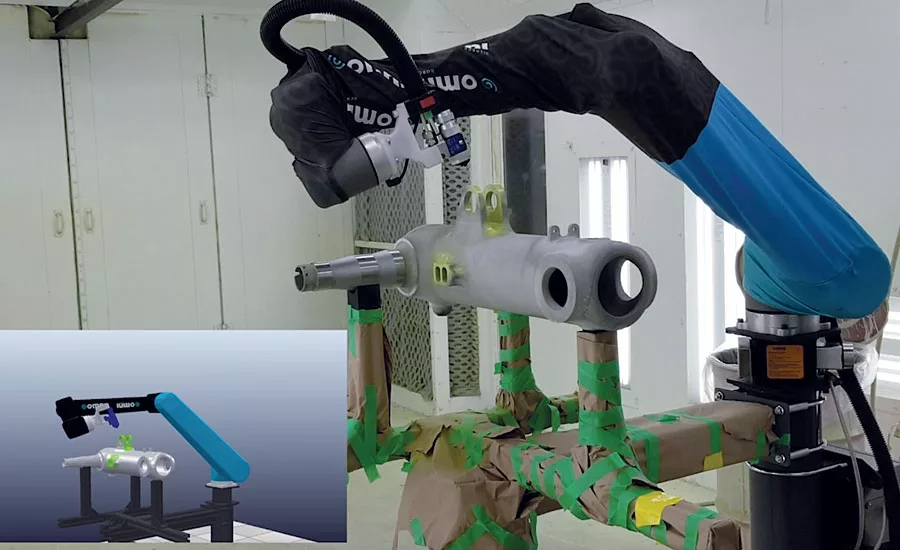

A self-programming robot is any robotic system that is able to generate an accurate, efficient robot motion program to accomplish specific goals while respecting both a robot’s and its work cell’s physical constraints. This self-programming framework requires a few key features not available with conventional industrial robots alone, namely: 3D vision control systems, AI-based task planning capabilities, and the ability to understand and generate programs in the languages understood by existing industrial robots.

Effectively, with this technology enabled, an industrial robot doesn’t need to be told “how” to do something, just “what” to do. For instance, a parameter could be set to paint a specific part face as defined in a CAD file, and then identify and generate a program for and paint that part in real time based on information derived from 3D visual scanners and reconstructed in a Digital Twin environment.

These capabilities are further applicable in real time on both stationary objects and those in motion on systems like an overhead conveyor. Because of this real-time ability to identify parts with 3D vision, the orientation and positioning of the part doesn’t make a difference to the quality of output or overall productivity achieved, meaning there is no need for planning and ordinancing of parts as they pass through the production environment.

With self-programming robots, coaters can essentially get human-like adaptability, but with the consistency, repeatability and throughput that robotic systems are known for.

Coatings Are Growing, But Labor Isn’t Keeping Up

This self-programming solution is coming along right when coaters need it most. Smart manufacturers know the benefits of the products that coatings manufacturers provide, and they’re looking for more and more ways to use them to increase the durability of their products and improve the value they offer to their consumers.

And yet, even with currently high rates of unemployment, skilled labor remains hard to find. If firms rush to train workers or increase throughput, quality and profitability often suffer. While demand may temporarily be slow, many of these firms have had consistent trouble maintaining profitability or have seen finishing processes as a production bottleneck - both of which are threats to manufacturers of industrial coatings.

The challenge to finding skilled labor has been long mounting, and data from the Fed shows that, before the crisis hit, the unit labor cost for manufacturers had been on an extended upward trend (Figure 1). While hiring and training new operators will help applicators make up some of the shortfall, the productivity and quality of work these operators offer will hardly compensate for their current needs.

In this environment, both coaters and coatings manufacturers need to get on the same page about the biggest bottleneck they face in applying coatings more efficiently and profiting from it: finding and retaining skilled labor. Where the challenges with the human workforce will remain high for the foreseeable future, self-programming robots would seem to be the way to go.

Interpreting the Latest Opportunities for Coatings Manufacturers

This new, unique technology can ultimately be a great opportunity to expand the long-term market for industrial coatings. First, robots can run all hours of the day while maintaining the same level of precision, speed and quality - something that we should never expect of humans, even if they could. While waste reduction is another benefit to coaters that comes from this technology, coatings manufacturers can benefit from the fact that higher throughput, less rework and greater combined productivity and profitability mean their absolute material needs can rise to meet every demand - particularly if there are cases where powder coaters are already recycling materials to begin with.

Some coaters may already be using reciprocating arms or automated spray booths, but these may often require touch ups by humans after the fact that reach beyond the real-time precision that self-programming robots can provide. Beyond that, the ability to specify a particular type of application to particular faces and sides of parts in a way that’s harmonized with their existing production process is a huge efficiency benefit to coaters big and small - whether they are job shops or Fortune 500 manufacturers.

Helping Coaters Get a Leg Up When They Need It Most

Industrial coatings have become a gradually larger market in recent years. Speaking personally, I can remember the days where a welded power rack (for weightlifting) was expensive enough on its own. Now that they have become more commonly available, brands like Rogue specifically advertise high-quality powder coating or Cerakote as a feature on the power racks they sell.

While home gym equipment has been sold out in light of COVID lockdowns, other agricultural, heavy equipment and constructed assemblies are continuing to bring industrial coatings closer to end consumers in more unique ways. Manufacturers of all stripes are looking for more ways to use coatings, but often they cannot find ways to apply the coating that is cost-efficient, scalable or adaptive to high-mix environments.

Self-programming robots offer the coatings industry that final transition into serving daily more of the consumer-facing businesses that drive our economic growth. As demand picks back up and consumers develop new tastes, coaters can easily, efficiently and effectively apply industrial coatings using the right technology, offering huge benefits for everyone involved.

For more information, contact sales@omnirobotic.

References

1 https://fred.stlouisfed.org/series/ULCMFG

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!