Optimization of Waterborne Coatings

Racing Towards a Sustainable Future and Aligning with a Circular Economy

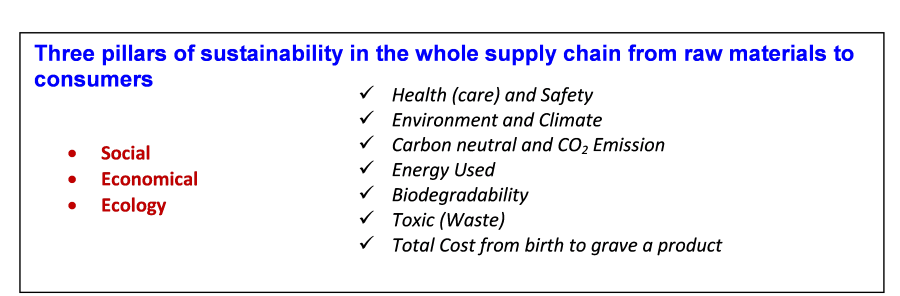

Some countries and world organizations are taking it upon themselves to make the world more sustainable. The United Nations, for instance, introduced its initiative, “Transforming our World: the 2030 Agenda for Sustainable Development,” a plan that highlights 17 UN goals for decreasing the carbon footprint. In the current scenario, industries face a big challenge to provide eco-friendly and sustainable products that have the same coating properties of current products. To work in such a direction, global trends and businesses must be aligned in efforts toward sustainability and concern for humanity.

Sustainable coatings, inks and adhesives must be migration harmless and comply with all four technical requirements of primary food packaging, which are:

- Low odor

- Low swelling

- Low-migration/migration harmless

- 3R Principle: - Recycle, Reduce and Reuse. In order to implement green printing, 3R is the basic foundation.

The linear economy “take, make, dispose of” production model is no longer useful, and a fundamental shift is needed towards a more circular and low-carbon model. The circular economy is the key element in the transition to a more sustainable economy. Its goal is to promote eco-friendlier and more conscious consumption and production, and encourage the repair, reuse and recycling of products. To make this vision a reality, companies need to follow a future path towards eco-friendly production by using waste as a resource.

The circular economy of food packaging is important to distinguish between the biosphere and technosphere. In the biosphere, circularity for packaging focuses on decomposition; in the technosphere, the focus is on recycling. By making these distinctions, the industry can more effectively understand the impacts that different recycling loops have on the natural world, whether these be open-loop, closed-loop or simply down cycling.

Circular Economy Advantages

- Reduction in resource and energy use

- Reduction in waste generation through eco-design and eco-innovation

- Stimulating innovation

- Contribution to the fight against climate change

In a circular economy, the goal is to eliminate waste and maximize the continual use of resources. Think of it as a loop that focuses on reusing, sharing, repairing, remanufacturing and recycling resources to minimize waste and pollution. For the printing industry, it is about creating a sustainable, green printing process that considers inks, materials, production efficiency, waste and recycling.1-7

To achieve the goal of sustainable products and maintain a circular economy, various ink manufacturers and printers are working toward a green printing process.

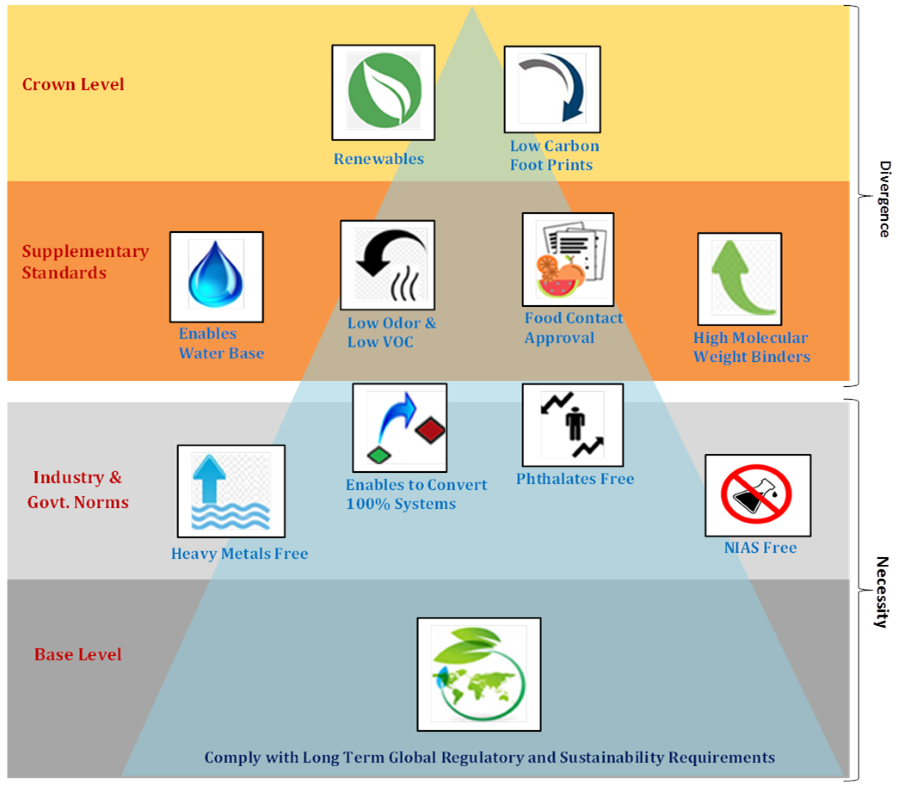

As per the advice of global regulation bodies, the following aspects must take into consideration; printing inks and coatings must have the following features:

- Lower Volatile Organic Compounds (VOCs): Solvents used in ink manufacturing must have low VOC content. Inks with lower VOC content have a lower emission level while printing, which is beneficial for the environment.

- Bio-Derived or Renewable Materials: It is generally considered that the use of bio-derived renewable oils is a good option for improving overall environmental impact, because these materials have lower VOC content. Vegetable-based inks, which are naturally low in VOCs, are a better alternative.

- Reducing the Use of Heavy Metals: Some inks consist of heavy metals like lead, arsenic, selenium, chromium, mercury and cadmium used for bright color printing. Such inks are toxic in nature.

- Reduced Use of Hazardous Air Pollutants: In order to reduce the environmental impact, minimizing the use of hazardous air pollutants (HAPs) is another effective alternative.

- Recyclable Products: When recycling paper, most inks are removed by the deinking process. But efforts are still continuing for the recyclability aspect of inks, and are under consideration.

- Reduced Hazardous Waste: Generally, solvent-based inks are classified as hazardous due to their flammability characteristics and should be avoided when possible.

All coatings manufacturing companies have the responsibility to get involved in the communities where their facilities are located and to use manufacturing processes that demonstrate environmental excellence through waste reduction, lower energy and water consumption, and robust safety performance measured by several key metrics like greenhouse gas emissions, energy and water consumption, carbon footprint, and safety record.

The coatings world needs to focus on the following important points during the development process of next-generation paints/inks/adhesives by achieving low VOCs and quality of printing, which enhances the product value.

Customer Focused

Due to the complexity of modern coatings, all manufacturing and research and development teams should work closely in partnership with customers and value chain contacts in order to make customized, innovative developments. They must be a customer solutions provider, offer a broad technology base with a wide choice of water-based technologies that can be adapted to individual customer needs.

Assuring Safety

The company/team should apply a tiered approach to the toxicity data needed to support the safety of food contact materials or coating materials. They must proactively monitor and/or retrieve supplier data on impurities of all raw materials likely to contain such traces.

Performance Properties and Application Testing Methods

They must have a vigorous set of testing methods that has to be developed based on years of experience within the industry and that meet or exceed the current ISO and ASTM norm standards. All customers need quality performance reports, which can help them to add value to their coating formulations.

New Technologies

New types of paints, inks and coatings materials should be developed based on technological advances. The safety of the materials used in these formulations needs to be evaluated. In some cases, revisions in global regulations were made to assure the safety of the food in contact with new technology with new materials used.

Due to low toxicity and flammability, low VOC levels and HAPs emissions, waterborne coatings are the first preference for sustainable products. Waterborne coatings use water as a solvent to disperse a resin, thus making these coatings eco-friendly. In most cases, waterborne coatings contain more than 50% water, with small quantities of other solvents such as alcohol and glycol ethers.

The key advantages to using waterborne coatings are listed below:

- Low toxicity and flammability due to low VOC levels and HAP emissions

- Help reduce air emissions

- Lower or no risk of fire from handling flammable solvents

- Less hazardous disposal

Water-based technologies are optimized for the global dynamic packaging market in order to cope with the diversity of demand. The use of one technology over another is usually due to a number of factors like regional market preferences, existing application systems, substrate choice and environmental pressures.

Conclusion

Manufacturing organizations have incorporated sustainable formulations that supports a circular economy by the inclusion of renewable raw materials, as well as water- and vegetable oil-based products in place of solvent-based like mineral oil.

They must follow the EEC VOC legislation directive, which has become one of the major driving forces behind the conversion to water-based systems. This, together with health, environmental and safety concerns, including the risk of fires and the reduction in manufacturers’ insurance costs, is continuing to push the conversion further. Advantages include possible faster degradation during recycling, lower rates of VOC emissions and lower levels of contaminants such as heavy metals.

Optimization of the CO2 footprint is a key trend that may mean logistics optimization. In order to reach that goal, organizations practices rigorous development processes and incorporate analytical tools to evaluate and improve the eco-efficiency of both its manufacturing procedures and products. This data-driven approach strives to set improvement targets for its processes on energy and water consumption, greenhouse gas emissions, and solid waste emissions, as well as develop products with a structured approach that includes risk management and eco-efficiency improvements as criteria.

This article has provided an overview of waterborne coatings and its exploration in the printing industry from various perspectives for offering immediate environmental benefits. Although new developments have offered enhanced quality and credibility in various ways, the importance of water-borne coatings is of prime significance. Efficient implementation of waterborne strategies in the printing industry are a way to offer all-around excellence. Water-based coatings aim at lower emission of VOCs and gases, reducing consumption of hazardous chemicals and carbon footprints during the production cycle in the printing industry. Waterborne coatings offer a holistic approach to sustainability in the printing industry. They not only provide immediate environmental benefits, but also ensure the health and safety of employees. Hence in this modern era, waterborne coatings are proving to be a boon for the printing industry. Waterborne sustainable coatings and circular economy is a regenerative system in which resource input and waste, energy leakage, and emissions are minimized by slowing, closing and narrowing the energy and materials introduction path. Organizations must commit to transforming business model spans for everything from how they source to how they design, deliver, recover, repair and reuse their products and solutions.

Acknowledgment:

The authors are grateful to Uflex management who helped them to put these ideas well above the level of simplicity and something concrete. We are thankful to Uflex Ltd. Chemical Division for providing infrastructure and constructive criticism that have helped us to accomplish this work. It is a genuine pleasure to express our deep sense of thanks and gratitude to our colleagues for their timely advice, meticulous scrutiny, scholastic advice and scientific approach to a very great extent.

Authors

Dr. Pinaki Ranjan Samanta has more than 26 years of experience in the areas associated with industrial research of coatings and testing of finished products and raw materials of coating-related products. He received M. Sc. and Ph.D. in the field of organic chemistry, also done PG diploma in paint technology.

Dr. Manisha has a Masters in chemistry from IIT, Roorkee, and a Ph.D. in chemistry with more than nine years of experience, and is currently with Uflex Limited, Noida as Manager (R&D), and prior to this, worked as Sr. Scientist with Jubilant Agri and Consumers Products Ltd.

Ms. Ritu Gupta has a Master's in Chemistry, is currently working with Uflex Limited, Noida as a Chemist (R&D instrumentation). She has research experience of more than two years with expertise in the area of analysis by using state-of-the-art instruments like Py- GC-MS, GC-HS, FTIR, UV-spectrophotometer.

Ms. Shweta Chauhan is an engineering graduate and has done B.Tech. in chemical engineering. She is a regulatory expert and is currently working with Uflex Limited, Chemical Division, Noida.

Mr. Anuj Johri is a post-graduate in Chemistry and MBA in Operations Management along with certified internal auditor of ISO 9001 with 23+ years of industrial experience in quality management and design and development of packaging inks. Currently, he is working with Uflex Limited (Chemical Division) as HOD – R&D (Inks) - accountable for the development of new formulations, new products.

References

1 Articles from Packaginglaw.com; A resource provides by Kehller and Heckman LLP.

2 Regulation (EC) No 1935 / 2004 of the European Parliament and of the council of 24 Oct 2004.

3 Food Packaging Science and Technology and PPT on “Food Contact Legislation and Migration by Sara Limbo, June 12 – 16, 2017, Tampere, Finland.

4 Presentation of Sustainability of Printing Inks in Packaging by Jack Baarends (Green 4 Print-June 2013).

5 EuPIA ,2012, Printing Ink Market Statistics. www.eupia.org.

6 Tetra Pak research study Consumer Environmental Trend Report– Sustainable Packages- October 2019 www.tetrapack.com.

7 Covid-19 Pandemic: Significance of Circular Economy and Plastic Packaging during this phase- By Dr. Pinaki Ranjan Samanta, Dr. Ruchi Gupta, Ms. Ritu Gupta, Ms. Shweta Chauhan and Mr. Anuj Johri- Ink world Magazine Issue, May-June 2020.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!