Highly Durable Coating System as an Alternate to Polysiloxane

Mild steel, also known as low carbon steel, is one of the most widely used metals in the construction industry. The percentage of carbon found in this steel ranges from 0.05% to 0.25% by weight, making it more weldable, more ductile and easier to handle than steel with higher carbon content. Due to the lack of alloying materials in mild steel, it is more subjected to oxidation, unless properly coated.

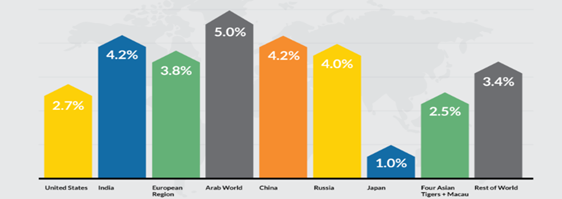

Mild steel is also affected by natural elements such as water, air, environmental pollutants, chemicals, etc. that can result in corrosion. The cost of corrosion is estimated to be USD 2.5 trillion, which is equivalent to 3.4% of global GDP (Figure 1). There is an extensive amount of data published worldwide stating that a thousand tonnes of steel is lost every year due to corrosion, resulting in a loss of millions of dollars every year. This has led to the development of various methods to protect the steel from rusting. These methods include protective coatings, chemical conversion, alloying and cathodic protection – protective coating being the most widely used.

Hence, many companies are constantly working to develop more resistant coating solutions through the development of new chemistries or other such allied technologies that delay the process of corrosion, leading to longer degeneration periods.

Traditionally, epoxy primers and weather-resistant acrylic polyurethane topcoats are a widely used system. This system generally offers protection on mild steel of up to five to seven years in terms of corrosion, paint film integrity, shade and color retention when applied at a thickness of 120 150 microns.

To further improve the durability of the coating, high-performance systems such as a zinc-rich primer followed by an epoxy MIO intermediate coat with an acrylic polyurethane topcoat at DFT of 300- 350 microns were introduced. In some cases, up to 450 microns of topcoats was introduced, yielding durability of up to 15-20 years with intermittent maintenance and touch-up coats.

This article studies the effects of weathering on the topcoats and focuses on a commonly used acrylic topcoat that offers a balance of properties such as chemical resistance, condensation resistance, gloss retention and other mechanical properties.

The percentage of nonvolatile content for acrylic resins generally varies from 60% to 75%, which makes it possible to achieve paint with maximum volume solids of 63%. However, there are acrylic resins available with percentage nonvolatile content in excess of 75% that are very slow drying in nature due to low glass transition temperature and high/low molecular weight that impacts the drying process at room temperature.

Polyester, an organic resin, is one of the closest alternatives to acrylic polyurethane chemistry, but it is not as widely used in general applications due to:

- Slow curing at room temperature;

- Selective compatibility with few solvents;

- Limited compatibility with universal colorants;

- Comparative low resistance to alkali;

- The ester linkages in polyester resin backbone are susceptible to attack of water and hydrolysis.

However, there are also advantages such as:

- Excellent durability;

- Acid resistance;

- Extended flexibility after curing, which makes polyester-based coating systems the most durable systems, as they retain adhesion on a long-term basis without turning brittle;

- Certain polyester formulations with the correct pigment show selective absorption of some of the visible or NIR radiations, due to which polyesters are the most preferred system for camouflage and coatings for the defense industry.

Looking into the ongoing investments in the infrastructure segment (bridges, metro stations, highrise buildings, etc.), structures are very difficult to maintain due to a variety of reasons, including very high labor costs. As a result, asset owners are looking for maintenance-free, highly durable coating systems.

In this category, inorganic polymer-based systems like polysiloxane are the obvious current choice. Based on the advantages and disadvantages, an argument could be made that a highly durable polyester resin system could be used as an alternative to an acrylic polyurethane system and polysiloxane system.

Experiment

The following experiments were conducted.

Selection of System: In order to study the performance and compare various systems, the following were selected.

Acrylic Polyurethane: The topcoat from an existing product range that is well established in the market and has a proven track record, was selected. It is based on an acrylic resin having the following specifications:

- Hydroxyl value 140 ± 10

- % Non-volatile 70 ± 2 %

- Tg = 35- 40 °C

- Styrene-free monomer combination

Polysiloxane: commercially established acrylic polysiloxane system. The lab data includes

UV – A resistance as per ASTM G 154 = 3,500 hours with gloss retention > 80%

Polyester System: Resin selection is one of the most important steps. Hence, it was important to select a resin (Figure 2) based on the cyclic monomers such as:

- CHDA – Cyclohexane dicarboxylic acid

- CHDM – Cyclohexane dimethylol

- IPA – Isophthalic acid and some saturated cyclic monomer

- The parameters of the resin were:

- Hydroxyl value 155 ± 10

- % Non-volatile 75 ± 2 %

- Tg = 35-40 °C

- Phthalic anhydride, maleic anhydride-free monomer combination

Typical Paint Formulation for White Shade

|

Sr. No |

Ingredient |

% by Weight |

|

1 |

Resin |

65.00 |

|

2 |

Polymeric dispersing additive |

01.00 |

|

3 |

Flocculating agent |

00.50 |

|

4 |

Rheological additive – pre-activated |

3.00 |

|

5 |

Pigment |

22.00 |

|

6 |

Flow additive |

01.00 |

|

7 |

Silicon free Defoamer |

01.00 |

|

8 |

DBTL – 1% Solution in Xylene |

00.50 |

|

9 |

PMA |

7.00 |

Paint Design Parameter

|

1 |

PVC |

9 -10 |

|

2 |

P/B ratio |

0.1/1 |

|

3 |

Hardener type |

HDI-based aliphatic isocynate |

|

4 |

-OH:NCO ratio |

1:1.1 |

|

5 |

% Volume solid |

58% |

Application Conditions

|

Substrate |

Hot rolled MS panel |

|

Surface preparation |

Grit blasting with G 25 grit |

|

Surface profile |

25-35 micron |

System of Application

|

Primer |

Epoxy zinc-rich primer having 80% zinc content on dry film |

65-75 µ |

|

Intermediate |

Epoxy high-build intermediate |

120-140 µ |

|

Topcoat |

Respective topcoats |

|

|

APU |

Acrylic polyurethane |

70-90 µ |

|

PE |

Polyester polyurethane |

70-90 µ |

|

ASi |

Acrylic polysiloxane |

70-80 µ |

Physical Performance Parameters

|

Sr No |

Parameter |

APU |

PE |

ASi |

Test Method |

|

1 |

Dry film thickness |

290-300 µ |

290-300 µ |

280-290 µ |

ISO 2808 |

|

2 |

Gloss @ 60° |

92-95 Unit |

94-96 Unit |

86-90 Unit |

ASTM D 523 |

|

3 |

Adhesion pull off |

7.2 MPa |

8.5 MPa |

9.2 MPa |

ASTM D 4541 |

|

4 |

Flexibility on MS panel 0.8 mm thickness |

Passes 7 mm |

Passes 6 mm |

Passes 7 mm |

ASTM D 522 |

|

5 |

Impact – Direct on MS panel 0.8 mm thickness |

1.5 kg x 12.5mm x 50 cm |

1.8 kg x 12.5 mm x 50 cm |

1.2 kg x 12.5 mm x 40 cm |

ASTM D 2794 |

Chemical Resistance as per ISO 2810 for 168 Hrs

|

Sr No |

Parameter |

APU |

PE |

ASi |

|

1 |

10% Acid resistance |

Passes without any visible film defect |

Passes without any visible film defect |

Passes without any visible film defect |

|

2 |

10% Alkali resistance |

|||

|

3 |

Aromatic hydrocarbon |

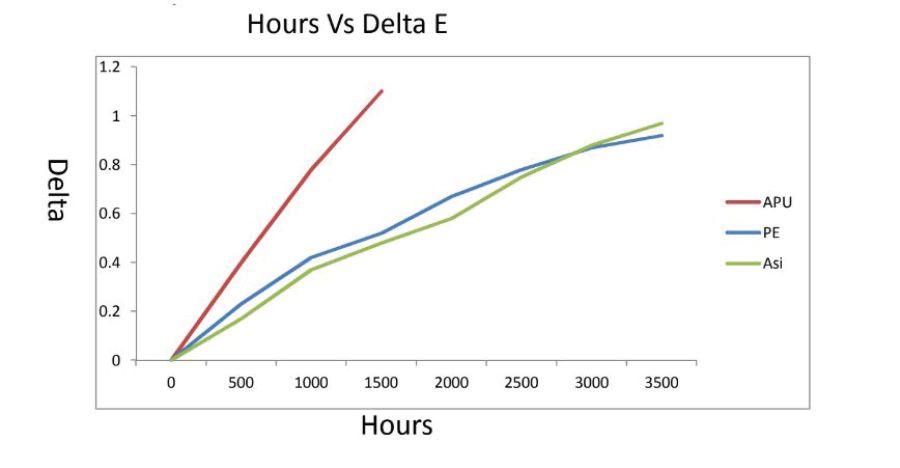

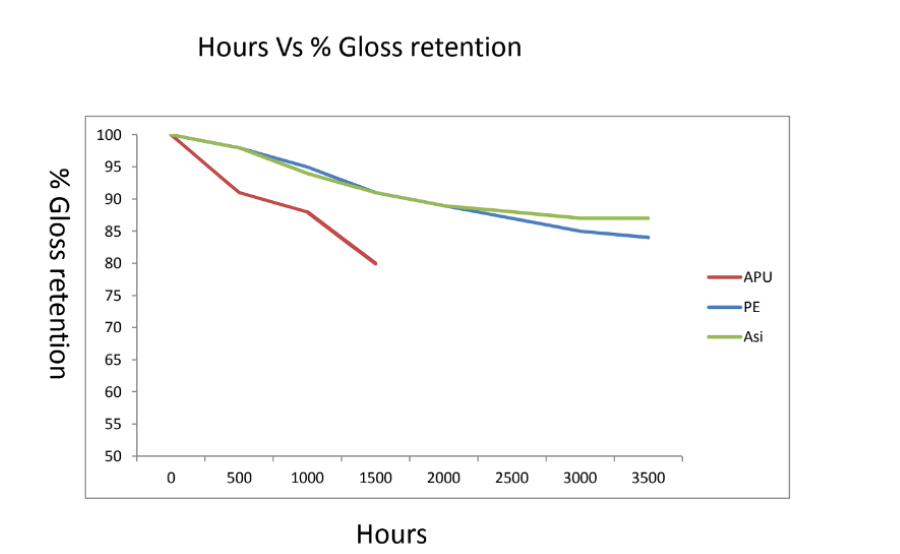

Weather resistance as per ASTM G 154

Test conditions: UV- A 340 nm-1 @ 50 °C for 8 hrs followed by condensation @ 40 °C for 8 hrs

|

Sr No |

No of Hrs |

Parameter |

APU |

PE |

ASi |

|

1 |

0 hrs |

Δ E |

- |

- |

- |

|

Gloss retention |

100% |

100% |

100% |

||

|

2 |

500 hrs |

Δ E |

0.4 |

0.23 |

0.17 |

|

Gloss retention |

91% |

98% |

98% |

||

|

3 |

1,000 hrs |

Δ E |

0.78 |

0.42 |

0.37 |

|

Gloss retention |

88% |

95% |

94% |

||

|

4 |

1,500 hrs |

Δ E |

1.1 |

0.52 |

0.48 |

|

Gloss retention |

80% |

91% |

91% |

||

|

5 |

2,000 hrs |

Δ E |

|

0.67 |

0.58 |

|

Gloss retention |

|

89% |

89% |

||

|

6 |

2,500 hrs |

Δ E |

|

0.78 |

0,75 |

|

Gloss retention |

|

87% |

87% |

||

|

7 |

3,000 hrs |

Δ E |

|

0.87 |

0.88 |

|

Gloss retention |

|

85% |

85% |

||

|

8 |

3,500 hrs |

Δ E |

|

0.92 |

0.97 |

|

Gloss retention |

|

83% |

84% |

Conclusion

The following can be concluded based on the above observations and results:

- Polyester polyurethane topcoat is closer in durability performance to acrylic polysiloxane.

- The theoretical proposition that performance of polyester can be improved when secondary hydroxyl and ester linkages are shielded. It is visible from the results that most of the deficiencies of polyester-based topcoats are addressed via new-generation polyester resins.

- This new-generation polyester resin can very well compete with siloxane with regard to durability.

Acknowledgement:

Author likes to express gratitude and regards to Mr. Bharat Chokshi, Mr. Ankur Chokshi and management of Grand Polycoats for giving an opportunity and encouragement to conduct experiments. Thanks to Mr. P Ramchandran and the R&D team who has contributed towards experimental work and data generation. Without their help, this paper would not have been possible. Grand Polycoats is an industrial paint manufacturer in India that specializes in High-Performance Protective Paints and Coatings.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!