Custom Coil Coating System Meets Production and VOC Removal Demands for Automotive Manufacturer

Every manufacturing operation that produces finished painted metal products needs to assess the benefits of using pre-coated metal coils or applying paint directly on the finished product. Epcon Industrial Systems pursued a feasibility study for a large automotive manufacturer regarding its transition from the painting of metal parts on-site to the coating of coils used for various automobile parts. Both the coil coating process and the post-painting of automotive metal parts are notorious for high thermal requirements in coater rooms, in-house spray booths, curing ovens and volatile organic compound (VOC) removal.

A re-engineered system with updated technology can not only increase the speed of the operations and output, but also improve the efficiency of the air pollution controls. This particular project objective was to design and assemble a new pre-painted metal production line equipped with a regenerative thermal oxidizer to remove the VOCs from the curing sessions. The client's initial perception of needed investments was highly expensive before Epcon's team proposed an integrated unit with optimized energy efficiencies and adequate process controls. This re-engineered process design would require minimal heat input with more than 85% thermal recycling throughout the system.

To better understand the system design and enhancements, it is important to have a greater context for the role of pre-painted metals and coil coating applications across industries. The coil coating industry is growing at an estimated compound annual growth rate of 5% for the forecast period of 2019 to 2025. With the overall demand for the production of pre-painted metals increasing from year to year, new coil coating technology advancements are able to increase the production efficiency for many process applications. For example, in the automotive industry the traditional method of metal parts processing consists of cutting and rounding edges before painting. This has several disadvantages, as each metal part has a specific shape. The paint application cannot be done promptly and efficiently because each part requires a separate operation, which increases the manipulation costs. In addition, the automated painting booths for the variously shaped metal parts are costly and challenging in terms of needing specialized robots that manage spraying directions for speed and uniformity. This requires highly accurate control systems that ensure applying liquid coating without wasted paint ending up outside the metal surface.

As a response to the mentioned disadvantages, the automotive industry became the third-ranked industry in the procurement of pre-painted metals. Today most automotive panels and parts like doors, body panels and bumper assemblies are commonly made of pre-painted metal in some of the world's greatest automotive factories. Because of the increased interest in pre-painted metal manufacturing methods, coil coating equipment and processes are being continuously optimized in terms of operational cost reduction, while simultaneously enhancing the products’ performance.

Another key advantage of pre-painting metals is that it ensures a consistent color, texture, thickness and the highest quality performance of finished products. Pre-painted parts certainly outperform post-painted application quality since coated coils are uniformly cleaned, pretreated and painted as a flat surface. The flat metal surface of the coil coating application contributes to the material's higher impact strength and enhances its scratch resistance. After brushing, to flatten the metal surface, the initial primer coating is applied to metal coils. Besides preventing the undercutting of paint and enhancing corrosion resistance, the polymers used for primer coating are tightly bonded to the metal, providing excellent adhesion. Achieving these uniform results in a post-painted approach is nearly impossible, as the parts are already molded into various shapes. Besides the obvious labor efficiencies, environmental benefits and energy savings, coil-coated material is inherently more consistent than those products produced on a part-by-part basis.

Challenges

A large automotive manufacturer already had a liquid coating process line mounted in the facility. As the production output requirements grew and environmental legislation became stricter, the production team faced several problems with the existing equipment and process design.

First off, finished automotive parts are especially unique, as they are exposed to a wide range of external conditions: tremendous temperature and pressure ranges, mechanical impacts and water exposure, and their mechanical properties need to remain constant in all scenarios. The automotive line’s current liquid coating process could no longer reach the latest impact resistance standards and coating durability requirements. The company’s in-house research and development team invented several coating formulations, however none of them had the durability and performance to satisfy the primary requests regarding mechanical features and product lifespan with the existing equipment in place.

In addition, achieving uniform peak temperatures during the curing phase was a challenge due to the curing oven configuration and demands. The customer required a line speed of 85 fpm to satisfy the expected product throughput. The curing oven's dwell time needed to be between 20 and 40 seconds to ensure consistent coating with the stiff bond to metal. To satisfy the curing time at that speed, the oven's length had to be approximately 50 feet. However, the greater the oven length, the more difficult it is to have uniform and efficient heating. In the counter flow regime of the air and conveyor belt, the air inlet temperature varies significantly from the air outlet temperature, leaving the strip heated unevenly. It is crucial to ensure that every part of the metal surface reaches the target peak metal temperature (PMT) during dwell time. The PMT required for this coil coating application was 480-500 °F, depending on the thickness of the aluminum strips.

Within that short period, the greatest challenge for the new design parameters is to achieve the desired coating durability by maintaining the uniform temperature distribution across the oven's length, through specialized thermal dynamic controls.

From the environmental regulations perspective, the greatest issue represents the VOC emissions that are by-products of the organic coating’s application. The highest VOC emissions occur in the coating rooms, followed by the curing ovens, where their evaporation occurs due to higher ambient temperatures. The type of VOCs released depends on the polymer used, but all VOCs are highly toxic for humans if inhaled. According to EPA standards, all VOCs from manufacturing facilities must be completely destroyed before exhaust gas emissions enter into the atmosphere. Thermal oxidization is the most commonly used technology for VOC removal due to exceptional efficiency, but this often causes overwhelming additional costs since required operating temperatures are around 1,500 °F.

Solution

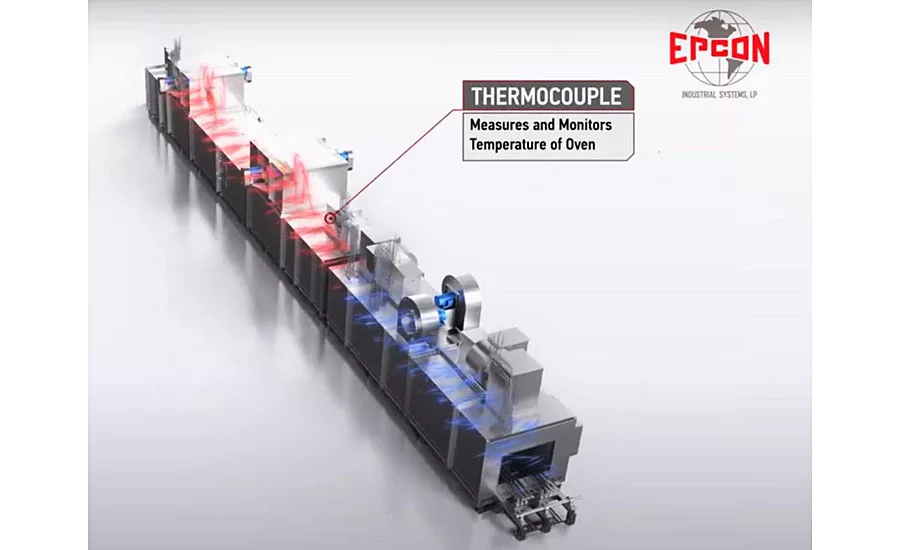

After a detailed analysis of the process requirements, Epcon’s engineering team developed a custom-designed coil coating system composed of coating rooms and curing ovens interconnected with heat exchangers and a regenerative thermal oxidizer (RTO) via an internal piping network. The custom-designed coating line provides an automated liquid covering of metal coils by passing through a series of rollers, ensuring a constant film thickness across the metal surface area, while the thermal oxidizer breaks down the VOCs in the exhaust gas so that no harmful emissions enter the atmosphere.

A typical organic coil coating line consists of decoilers, entry strip accumulator, cleaning, chemical pretreatment, primer coat application, curing, final coat application, curing, exit accumulator and recoilers. Therefore, the aluminum sheet passes through the curing oven at two junctures; after the primer coat application and again after the final coat application.

Curing ovens are specially designed with a no-heat flash tunnel and two independent temperature zones to meet exact process requirements. The operator is able to define the setpoint in both zones corresponding to the specific composition of organic coating applied to the metal surface. The accomplishment of two different temperature setpoints during the continuous process enables optimal polymer atomic structure transition while forming stiff and durable bonds. Both oven zones are comprised of one combustion chamber installed on the side of the oven equipped with a gas-fired burner and gas train. Each combustion chamber has a burner and a 30,000 cfm recirculation fan that evenly transfers heat across the section’s length, enabling the uniform temperature distribution with minimal deviations. The flash tunnel is located at the entry of the oven with insulation, and is void of recirculation or heating capabilities. The oven has top- and bottom-mounted supply plenums through which heated inlet air enters the oven while being evenly distributed through each section by forced flow, induced via recirculation fans. The heated air from the secondary heat exchanger coming to the oven has a sufficient temperature with only a minimal heat requirement, added by automatically controlled natural gas combustion to reach the oven’s setpoint.

After the aluminum strips pass through the oven, they enter the cooling chamber, which is a push-pull type used to reduce their temperature. The cooling chamber is mounted at the end of the curing oven, and it is provided with one ambient air supply fan that cools the strip via a convection mechanism and a 55,000 cfm exhaust fan. The inclusion of the cooling chamber is essential for enabling instantaneous material handling and continuous process resumption.

The VOC-laden exhaust air then flows from the coater room and curing ovens through interconnected pipes to the primary heat exchanger. There, the exhaust air is pre-heated by treated clean air coming from the oxidizer outlet. After passage through the primary heat exchanger, the temperature difference between the thermal oxidizer's setpoint and VOC-rich exhaust gas temperature is significantly reduced. The required additional heat is supplied from the natural gas booster burner mounted perpendicularly to the exhaust gas airflow in the oxidizer's combustion chamber. The perpendicular assembly and specially designed nozzles enable the air's turbulent flow, mixing all fluid layers and reaching a required temperature of 1,500 °F to ensure the successful and complete oxidation takes place.

The RTO structure design was quite complex, and Epcon's engineering team had to determine the thermal oxidizer's required dimensions according to the client's predefined VOC evaporation rate from both sources – the ovens and coater room. The two-chamber RTO’s length and capacity are specifically designed to maintain the 1-second residence time, taking into account the volume flows of the exhaust air from the process sources, and additional air intake provided by natural gas burners. The mentioned residence time is crucial to secure complete VOC oxidation without any residual emissions. Components of a traditional RTO include a system fan, motor, burner, heat exchange media, flow control valves, electronic and automatic system controls, temperature recorder, and exhaust stack. The system is typically lined with ceramic or media fiber insulation, while its exterior is comprised primarily of steel.

Conclusion

Applied coatings meet the highest impact strength and scratch resistance standards due to optimal curing of the coating with temperature uniformity in the curing oven within ±5 °F. The specially designed and energy-efficient thermal oxidizer removes more than 99% of VOCs while simultaneously providing thermal energy for curing ovens and even some other processes in a manufacturing facility. Therefore, coil coating operation costs are tremendously reduced due to carefully engineered thermal integration throughout the system.

All process variables are constantly adjusted and maintained with Epcon’s pre-tested control system made up of thermocouples to measure temperature, fans and spray nozzles adjusted by variable frequency drives, a custom PLC and operating interface panel. The negative feedback control loop parameters are tuned by the Epcon engineering team according to defined setpoint temperatures in each oven section and thermal oxidizer as well. The most notable control system performance is reflected in the fastest speed of setpoint achievement, enabling short oven dwell time while forming bonds of the highest strength and quality. Most importantly, users can in real-time assign process variables, control and monitor complete integrated units remotely from one place using user-friendly software.

The described integrated unit represents the highest quality, economically viable and ecologically compatible solution for the coil coating process and VOC removal. For this parts manufacturer, the presented design provides the ability to successfully meet enormous production capacity demands in the continuous process that is a must in the modern automotive industry.

For more information, visit Epcon's website.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!