Antifouling Coating from PPG

The latest addition to the successful PPG Sigma Sailadvance range and a significant breakthrough in antifouling technology, PPG Sigma Sailadvance NX coating was specifically developed to provide maximum hull protection and vessel performance in line with the requirements arising from International Maritime Organization (IMO) energy-efficiency measures. The coating delivers significant savings in fuel and related carbon dioxide (CO2) emissions, resulting in lower total operational costs and improved contribution toward global carbon-reduction measures.

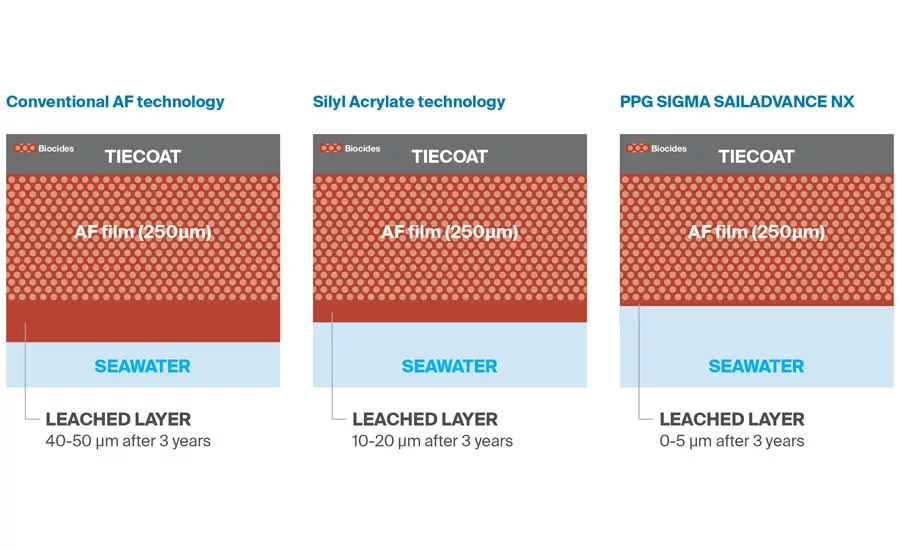

The culmination of 10 years of intensive product development by PPG’s resin synthesis experts, PPG Sigma Sailadvance NX coating delivers real linear polishing, a minimal leached layer and protection against a broad spectrum of global fouling conditions.

Formulated using PPG’s proprietary zinc methacrylate controlled surface active polymer (CSP) resin, PPG Sigma Sailadvance NX coating reportedly delivers ultra-premium performance with minimal speed loss of 1.0% to 1.5% on average over the operational period as well as improved fuel-saving capabilities and up to 15% CO2 savings.

The coating uses a binder formulation that provides real linear polishing that is unaffected by changing seawater temperatures and minimizes the development of a leached layer. Tests and applications with existing customers show no performance loss over the period of operation, with the coating reliably achieving 45 days of idle-time protection.

PPG reports that its PPG Sigma Sailadvance NX coating also contains an ultra-strong biocide package that targets a wide range of global fouling growth conditions, from bacterial slime and soft fouling to aggressive animal fouling.

“In developing PPG Sigma Sailadvance NX coating, our goal was to overcome the major challenges of antifouling technologies with a unique binder that ensures constant biocide availability on the hull surface and protection against broad fouling conditions,” said Ariana Psomas, PPG Global Segment Director, Newbuild and Dry Dock. “The new antifouling technology delivers significant CO2 savings during operation and guaranteed long-term static protection, making it an effective solution to meet emerging industry needs.”

PPG’s ultra-premium zinc methacrylate CSP resin gives a molecular structure with twice as many reactive sites to promote chemical hydrolysis than other acrylate technologies. This allows hydrolysis to be carefully controlled and results in a minimal leached layer and true linear polishing. It also ensures that biocide availability is controlled to the level required for maximum and stable protection over the operational period and while stationary.

To learn more, visit www.ppg.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!