A New Breed of Smart Inhibitor

As the world is awakening to a new green era, one of the biggest inefficiencies is left unaddressed. It is estimated that 40% of all new steel is used to replace steel damaged or destroyed by corrosion. This equates to an estimated 3.2% of the world’s CO2 emissions on maintenance alone.1

Within the oil and gas industry, corrosion is known to be one to the main reasons for the failures of infrastructure.2 According to NACE International, the annual cost of corrosion to the oil and gas industry in the United States alone is estimated at $27 billion – leading some to estimate the global annual cost to the industry as exceeding $60 billion.3

Evidently, all metals are susceptible to corrosion, but the nature of crude oil itself promotes corrosion further due to its harmful impurities like napthenic acid and sulfur. Plus, the issue is further exacerbated within the industry as 90% of the materials used within the oil and gas network are metals.3 Therefore, the effective management of this natural phenomenon will not only save companies money but will also save the environment through saved resources, and less repairing and replacing.

Phasing Out Hexavalent Chromium

For decades, numerous key industries such as marine, automotive, and oil and gas have relied on hexavalent chromium [Cr(VI)] for protection against corrosion. This chemical is clearly highly effective in its objective of protecting metal assets, however, it is also known to cause cancer in humans and animals.4

Since being phased out, a popular alternative in the oil and gas industry has been zinc phosphate. Albeit somewhat effective, this inhibitor does not match the performance of chromate complexes; and despite extensive research since the 1980s, hexavalent chromium remains the benchmark corrosion-preventative compound in most industries.5

A Highly Effective, Sustainable Inhibitor

Due to its micro-reservoir technology, a ‘new breed’ of inhibitor is currently driving innovation in the protective coatings market. Hexigone Inhibitors’ Intelli-ion® incorporates an active ingredient that has never been used effectively within coatings – making it a completely unique innovation.

The technology protects in a ‘smart’ way via three modes of electrochemical protection. The active ingredient sits dormant in a micro-reservoir and is triggered on demand when corrosion is sensed at the coating surface – via ions or pH changes. Ions that pass through the coating are sequestered, rendering them neutral and also triggering the release of the inhibitor to migrate to the metal surface.

A defect in the coating or at a cut-edge once under corrosive attack would have the same response from the reservoir system. The inhibitor forms a protective nano layer over the bare metal surface at the anode and cathode, and forms insoluble salts with any dissolved metal ions preventing mass transport of corrosive ions, as well as moderating under-film pH.

Independent Proof of Performance

Due to this unique approach, over 40 coatings companies worldwide are formulating with this product, with exciting results in the protective, coil and aerospace industries. Hexigone is currently supplying a leading marine coatings manufacturer, Teal & Mackrill Ltd. (Teamac), who has demonstrated remarkable results when comparing performance against their current zinc phosphate inhibitor.

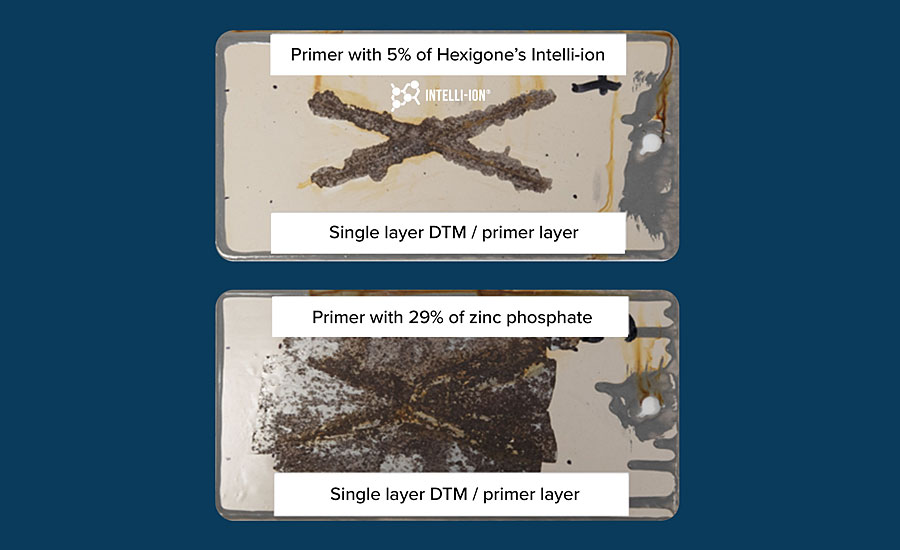

The top panel in Figure 1 was coated in a Teamac 2K epoxy primer containing Intelli-ion AX1 and no zinc phosphate. The bottom panel was coated in the same primer but contained zinc phosphate only. The samples were then scribed with a 1-mm cutter and placed into the salt spray chamber in racks at an angle of 45°. The chamber was run in accordance with ASTM B117 continuous salt spray fog testing. This consisted of creating a fog of 5% w/v NaCl in distilled water at pH 7.0 at 35°C consistently for 250 hours.

Following completion of 250 hours of accelerated weathering (ATSM B117), the panels clearly show superior corrosion protection with the 5% addition of the new inhibitor. The panel containing 29% zinc phosphate immediately peeled off, revealing extensive corrosion damage and no adhesion given the longer intact system. These results also show that by using Intelli-ion, the weight percent of inhibitor required is greatly reduced.

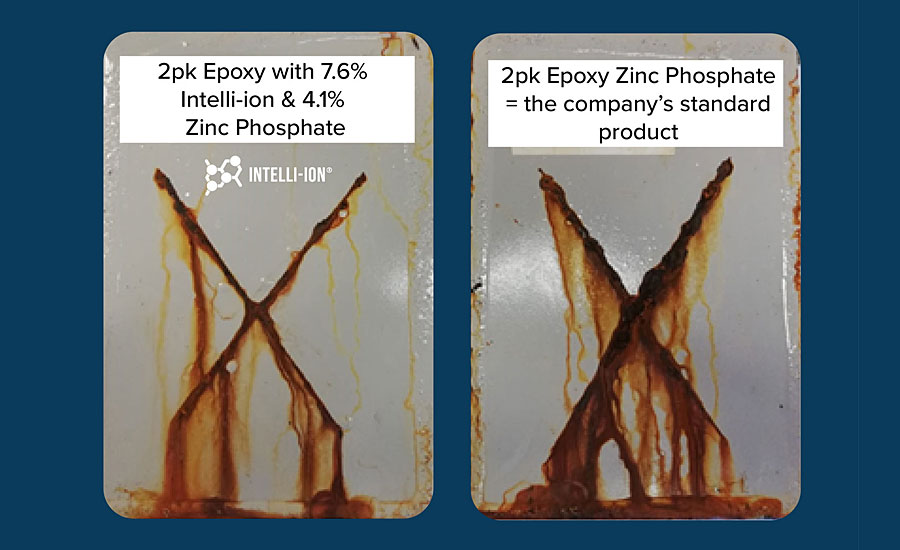

Furthermore, the new product range has been shown to work highly effectively alongside more traditional inhibitors such as zinc phosphate, with performance jumping when the products are used in synergy. In Figure 2, Teamac added Intelli-ion and zinc phosphate to a 2-pk epoxy primer and compared it to their existing zinc phosphate system. Following 750 hours ASTM B117, the company’s standard inhibitor was shown to be less effective than the new combination of Intelli-ion and zinc phosphate combined.

When considering that between 1990 and 2012, 9,000 oil and gas pipeline failures due to internal corrosion were reported3 – accounting for 54.8% of all spills – it easy to see the real-world potential of these results, both financially and environmentally.

One cost analysis with an oil and gas refinery found that just one of their off-site chemical storage tanks costs them $374,000 to repaint every 15 years due to corrosion. Hexigone’s AX1 has shown to increase metal asset longevity by about 50% and can therefore increase the life cycle of the tank by seven years, halving the maintenance costs per tank.

In-Depth Analysis via SVET and Natural Weathering

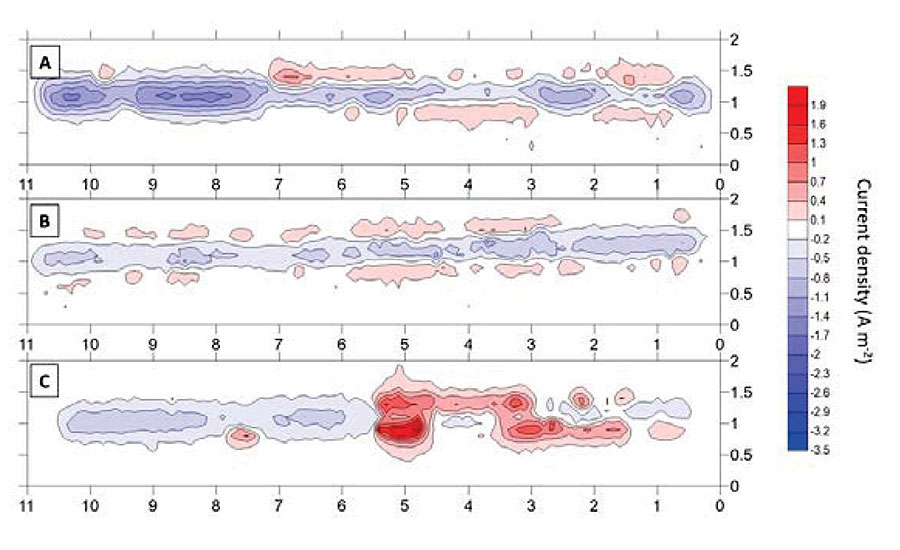

Further analysis of this product has recently been published in Surface Coatings International by Auckland University Researcher, Sina Sheikholesami, who was investigating the correlation between the scanning vibrating electrode technique (SVET) and natural weathering for analyzing corrosion. SVET is used to study localized corrosion behavior by giving spatially resolved corrosion measurements of microstructural changes in the material. The results demonstrated that by using SVET, the industry can accurately understand how an inhibiting system is performing in 24 hours, versus nearly nine months natural weathering.6

In this study, products A and B are Intelli-ion technology, and product C is a market-leading chrome-free inhibitor. Sheikholeslami reported that the SVET maps show that the inhibitive species released at the cut edge by coating systems containing Intelli-ion were more efficient than the alternative chrome-free system.6 This is visible via the red areas in Figure 3, which highlight high levels of anodic corrosion in product C following 24 hours exposure in 5 wt. % NaCl solution.

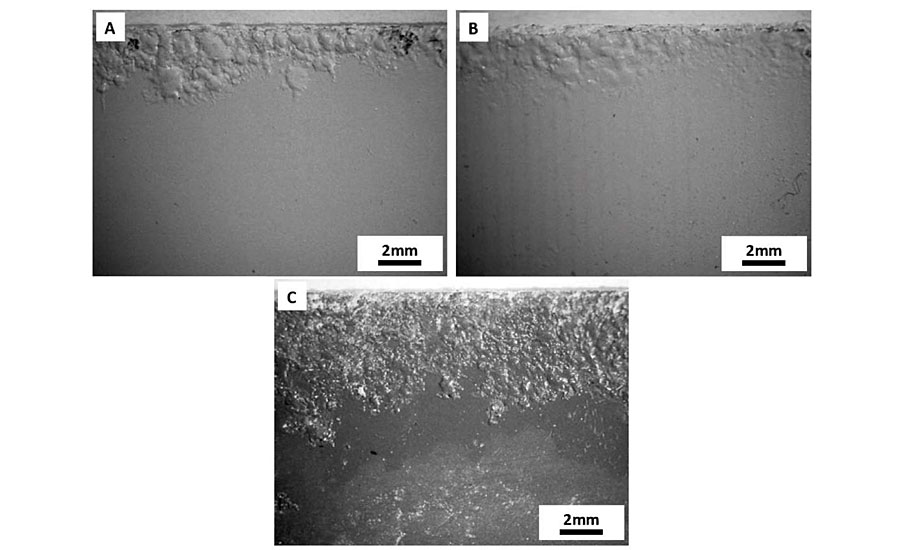

Furthermore, these laboratory results correlated with natural weathering testing performed at Muriwai beach site in New Zealand. The three coated panel systems A, B (Intelli-ion) and C (chrome-free alternative) were assessed following 10 months of exposure according to the AS/NZS 2728 standard. Figure 4 shows that product C has significantly more undercutting and corrosion than both the Intelli-ion products, which supports the SVET analysis previously carried out.

Conclusion

In the oil and gas industry, it is vital to maintain the integrity of pipeline infrastructure to avoid economic and environmental disasters. Following the phasing out of hexavalent chromium, there was a clear need for innovation in order to offer the same level of protection against corrosion. Through pioneering micro-reservoir technology, Hexigone is able to incorporate chemicals that were previously incompatible with coatings and offer a smart inhibitor that delivers on price and performance.

Independent testing by coatings manufacturers and researchers have validated the performance of Intelli-ion technology through industry-standard testing such as ASTM B117, natural weathering and SVET maps. These results clearly demonstrate that when used in a primer system, the additives dramatically increase the corrosion protection, enabling coatings manufacturers to offer a differentiated product that results in reduced maintenance cycles and economic savings.

References

¹ C. Hoffmann, M.V. Decarbonization Challenge for Steel. Retrieved from McKinsey & Company: https://www.mckinsey.com/industries/metals-and-mining/our-insights/decarbonization-challenge-for-steel#, (2020, June 3rd).

2 Kausalya Tamalmani, H.H. Review of Corrosion Inhibitors for Oil and Gas Corrosion Issues. Applied Sciences, 16, (2020).

3 Papavinasam, S. Corrosion Control in the Oil and Gas Industry. Houston, TX: Elsevier Inc., (2014).

4 United States Department of Labor. (2020, December 9th ). Hexavalent Chromium: Health Effects. Retrieved from United States Department of Labor: https://www.osha.gov/hexavalent-chromium/health-effects.

5 O Gharbi, S.T. Chromate replacement: what does the future hold? Nature, 8, (2018).

6 S. Sheikholeslami, L. G. Evaluation of cut-edge corrosion in environmentally friendly waterborne coil-coatings using the Scanning Vibrating Electrode Technique (SVET). Surface Coatings International, 5, (2020).

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!