Ultra-Low-Temperature Cure for MDF Applications

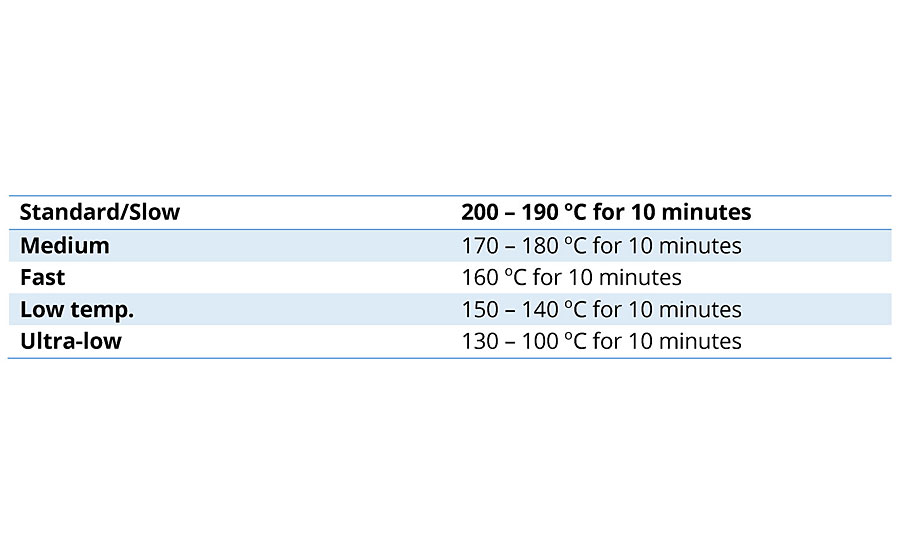

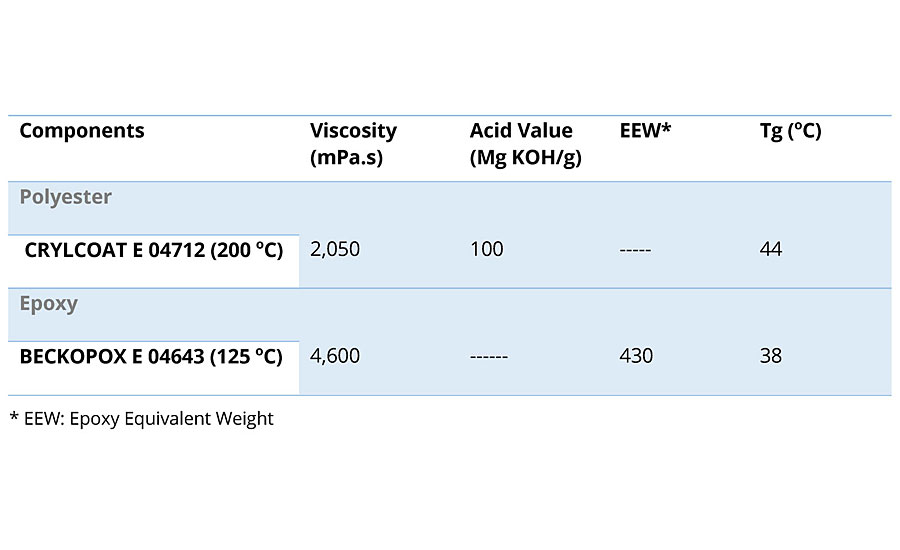

When powder coating technology was discovered in the 1940s and 1950s it was primarily used on metal substrates. Most thermoset powder coatings typically cure at 190-200 °C (metal temperature) for 10 to 15 minutes in a conventional oven. These temperature ranges were determined to be adequate to realize full cure without degrading the integrity of the formulated products, as full cure is required to achieve the desired performance benefits (Table 1).

As powder technologies continued to mature through the years, the need to further lower the curing temperatures has become more significant. In the past few years, there have been various developments of low-temperature cure technologies ranging from medium and fast down to low-temperature cure systems (Table 1) driven by the need to increase output, lower energy cost, and to conform to the environmental and regulatory policy to switch away from solventborne coatings. Most recently, we have seen a strong demand for the ultra-low-temperature cure technology for heat-sensitive and non-metal substrates such as wood and plastics.

Why Ultra-Low-Bake Powder Coatings?

Based on market analysis conducted by Research and Markets, the global wood coating resins market was estimated at USD 3.9 billion in 2020. It is projected to reach USD 5.1 billion by the year 2027. Another study by Irfab in 2017 estimated that the global domestic use of kitchen and office industrial wood furniture resins in the powder coating market is expected to reach USD 45 million, representing about 40% of the total market in North America and Latin America, with the estimated value of USD 18 million.

The ability to coat thermally sensitive substrates is one of the reasons for the heightened demand for ultra-low-cure and fast-curing powder coatings. This need comes with such benefits as offering a simplified process for industrial wood, design freedom for complex shape components in MDF and cabinetry, shifts in regulatory policies to switch away from solventborne to more environmentally friendly coatings, and the ability to coat thinner, heat-sensitive metal sheets.

Another reason for the demand of the ultra-low-cure technology is the need to cure slow-to-heat components. Massive metal components by nature are slow to heat and take longer to cure (Figure 1). They also consume time and energy. Lower curing temperatures means massive components can be coated faster, thereby increasing throughput and productivity. Lower cure temperatures also increase applicator production efficiency and energy savings.

Ultra-Low Bake Challenges

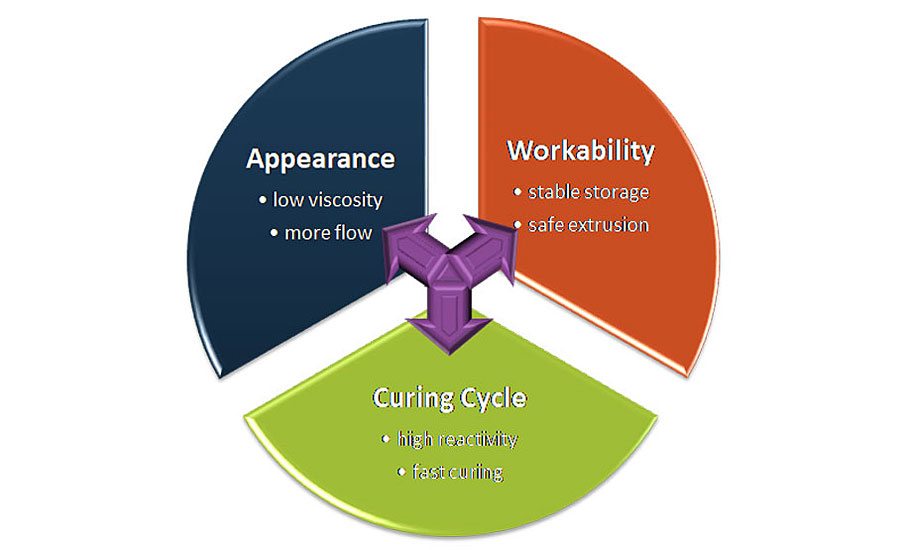

Appearance, workability and curing cycles are the three major hurdles that must be overcome to balance the desirable properties and coating performance of low-temperature and fast-curing powders. Appearance depends on low viscosity and high flow of the entire formulated product. Workability is the measure of the overall handling of the polymer and the processing of the formulated powder such as storage stability, safe extrusion, grinding and application. Workability is also influenced by the glass transition of the polymer, which must be high enough to ensure stability. High reactivity, fast curing and coating appearance, such as orange peel, good chemical resistance and mechanical properties, are another set of challenging factors that depend on the curing cycles (Figure 2).

It is in the light of these challenges that the novelty of an advanced chemistry for interior nonmetallic applications is presented in this article.

An Advanced Chemistry for MDF Coating

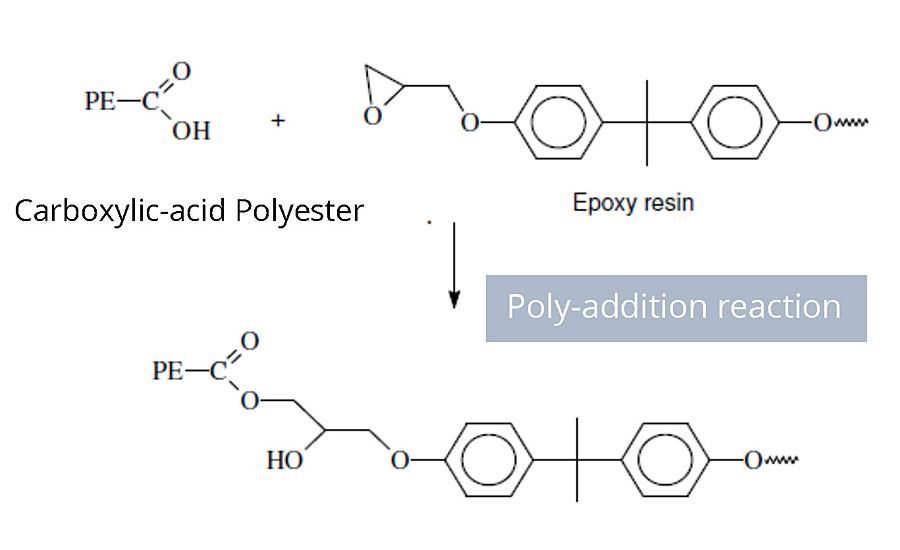

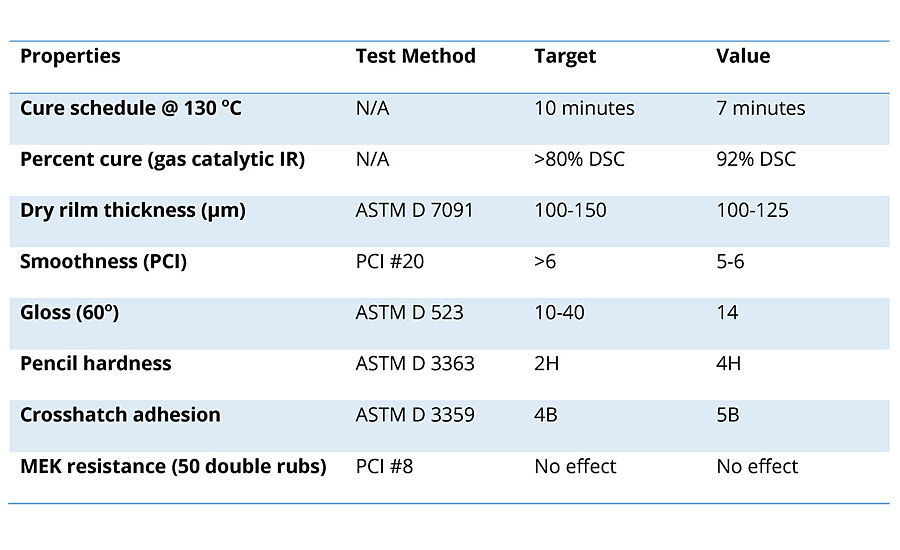

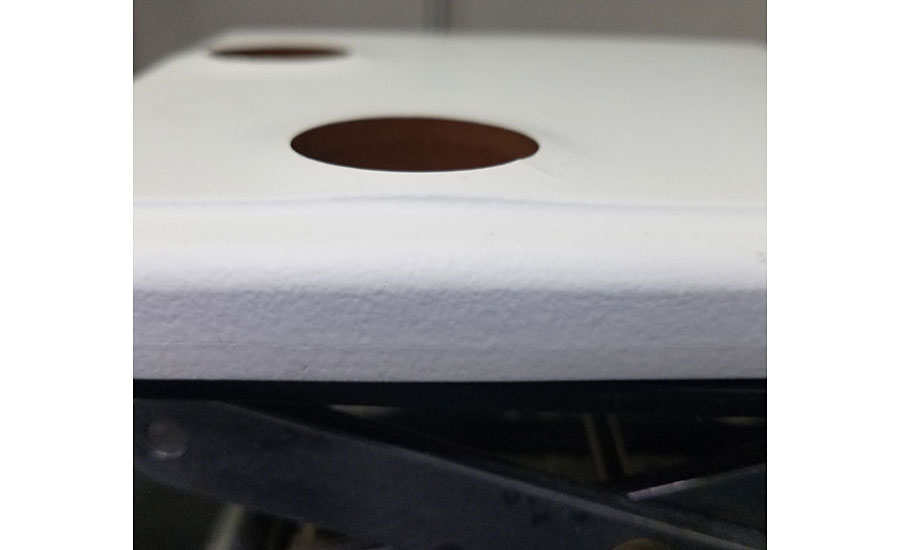

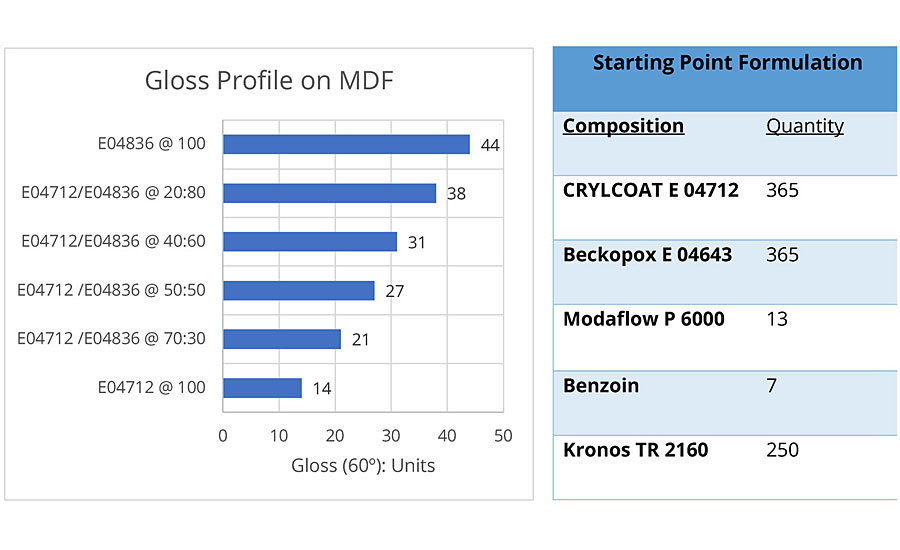

The new innovative and performance-oriented technology is designed to meet the delicate balance of the low-bake conditions for coating MDF. The technology is based on unconventional polyester-hybrid technology with a complete binder package approach that offers synergistic performance benefits of flow, smoothness, excellent chemical and stain resistance, adhesion on MDF and metal, ease of workability, and one-shot matte capabilities at low temperatures (Figure 3 and Table 2).

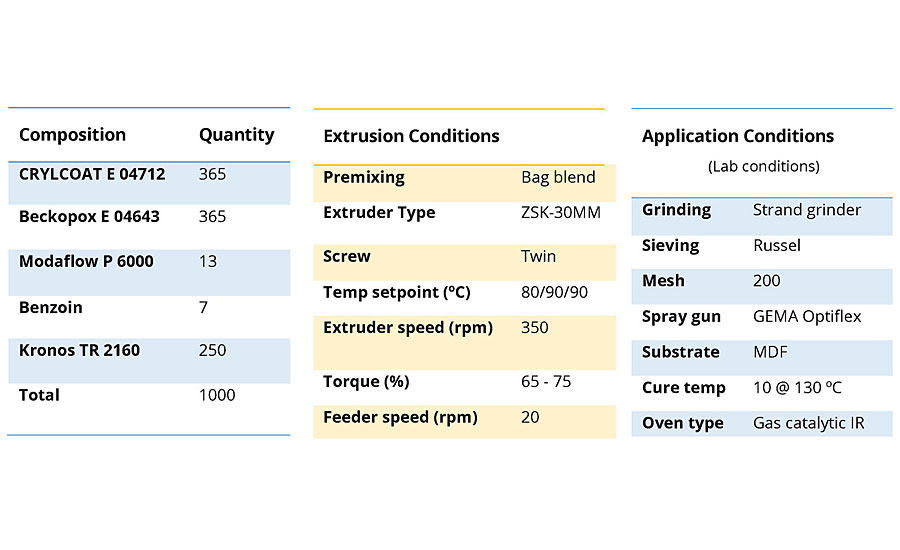

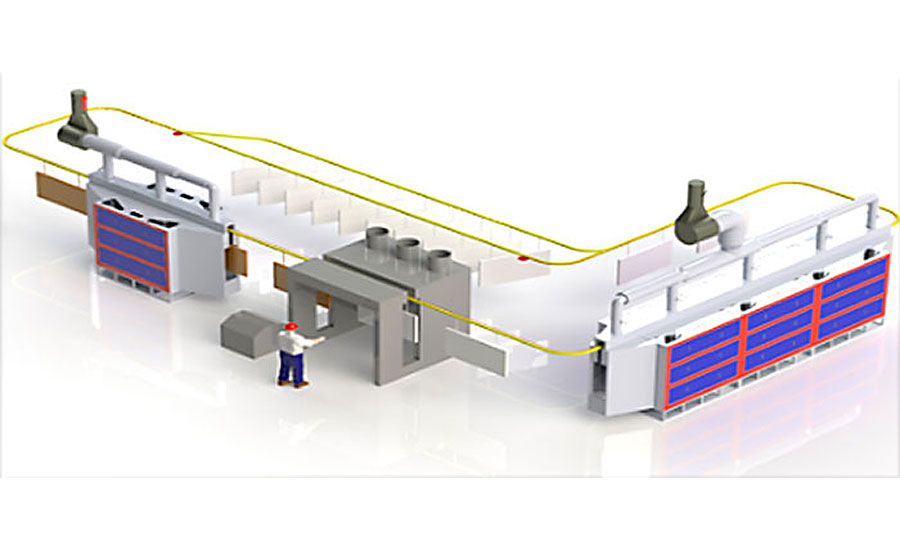

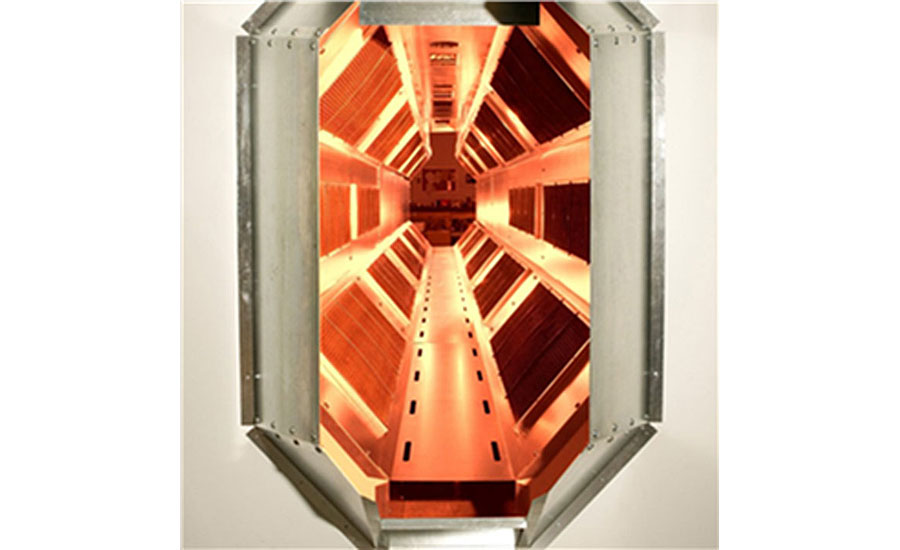

This platform is compatible with the conventional powder coatings manufacturing conditions. Although the product could be cured in a conventional oven, optimum smoothness and matte development are best achieved using gas catalytic infrared (IR) ovens. This process does not rely on heated, moving air to increase the part temperature and therefore does not add significant energy to the substrate. The capability of this platform to build up to 125 microns of dry film thickness on a single pass is not only beneficial to hide the MDF micro-fibers but also reduces the operational costs associated with multiple sanding in the liquid paint. The new innovation, combined with the recommended robust process steps as presented, will achieve the desired finishes (Table 3).

Processing and Thermal Cure

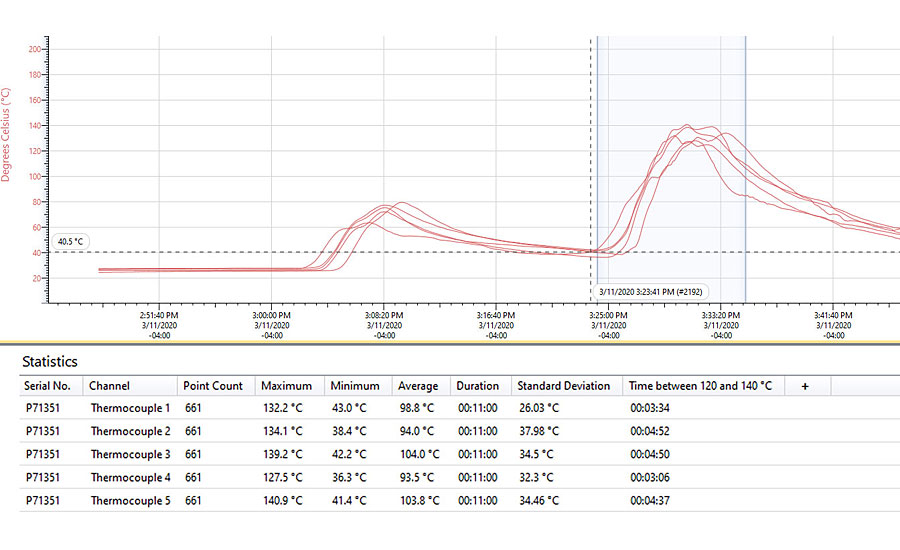

The quality of the coating based on this new technology is maximized when cured under the catalytic gas infrared oven. Refer to Figures 4-7 for oven layout, pre-heat and cure.

Figure 8 indicates the oven minimum temperature and time required to achieve complete cure. This technology is designed to withstand diverse process conditions and to overcome commonly occurring film defects such outgassing associated with poor-quality MDF.

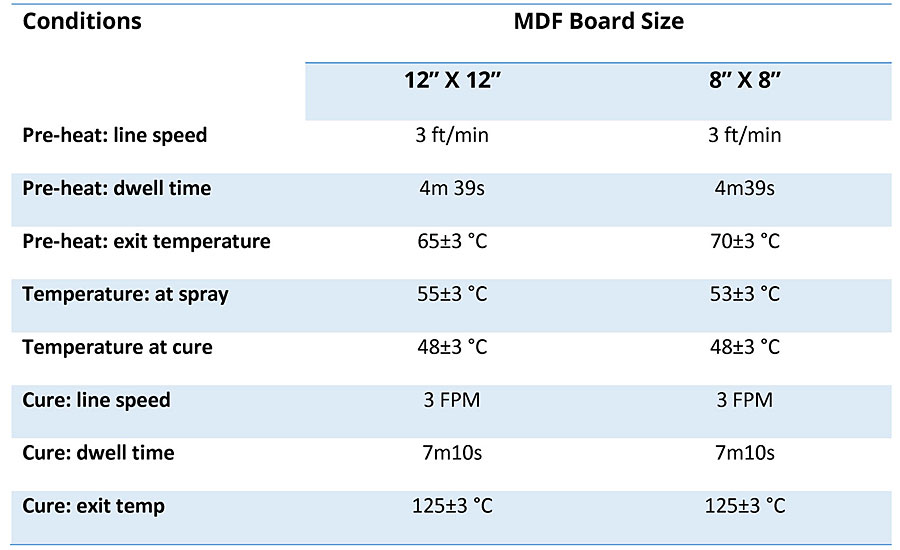

Table 4 shows the process steps in handling varieties of MDF boards curing at average temperature of 125 °C for five minutes (object temperature).

Coating Performance Characteristics

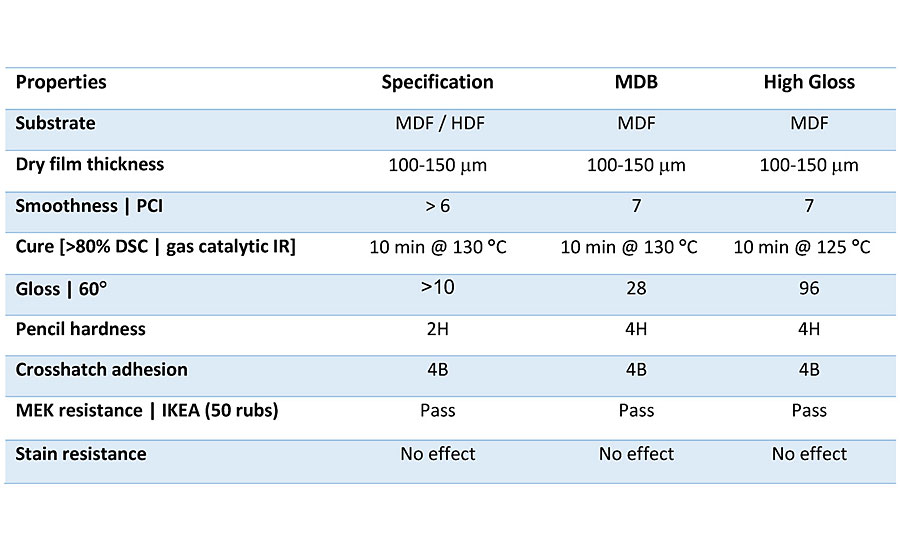

Table 5 summarizes the basic coating performances against the industrial requirements for kitchen and bath cabinet applications. The MDF boards selected in this evaluation were readily available online or over the shelf. Different geometric parts were evaluated to verify consistency in appearance and performance. Based on the configuration of the infrared ovens and paint part hangers, it could be challenging to achieve even distribution of the energy on the entire part surfaces. The use of different contours of MDF in the test does not only guarantee the performance consistency of the parts but also validates the robustness of the new technology. The high film build was targeted to avoid multiple coats and sanding.

The edge cracking test is a stringent requirement established by IKEA to determine the chance of cracking of a powder coated MDF and wood boards. When subjected to this test, this new technology shows excellent performance with no cracking after 48 hours of exposure, as demonstrated in Figure 9.

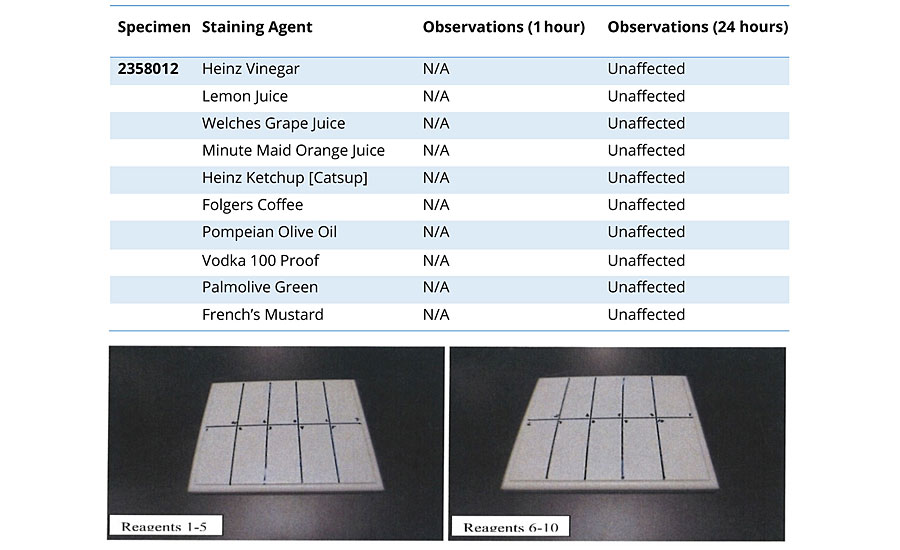

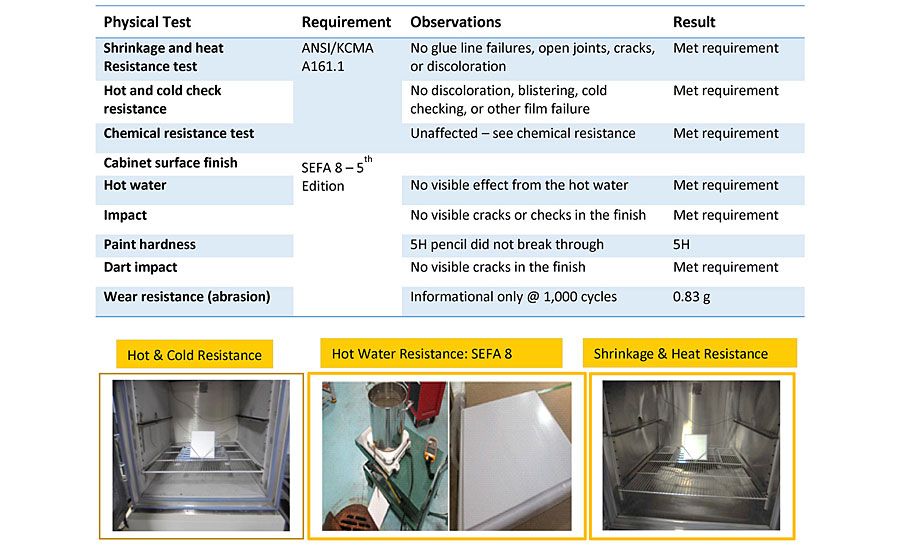

As the coating is intended for kitchen and bath vanity cabinets, this technology is designed to withstand certain substances and the harsh environment typically exposed to the kitchen and bath. Per Tables 6 and 7, the stain resistance and destructive physical test conducted by a certified independent testing lab per ANSI/KCMA A161.1-2017 showed no discoloration, stain or whitening of the coating after 24 hours. The results also met the requirements of the destructive physical tests conducted by per ANSI/KCMA and SEFA 8-5th edition standards.

Storage Stability and Handling

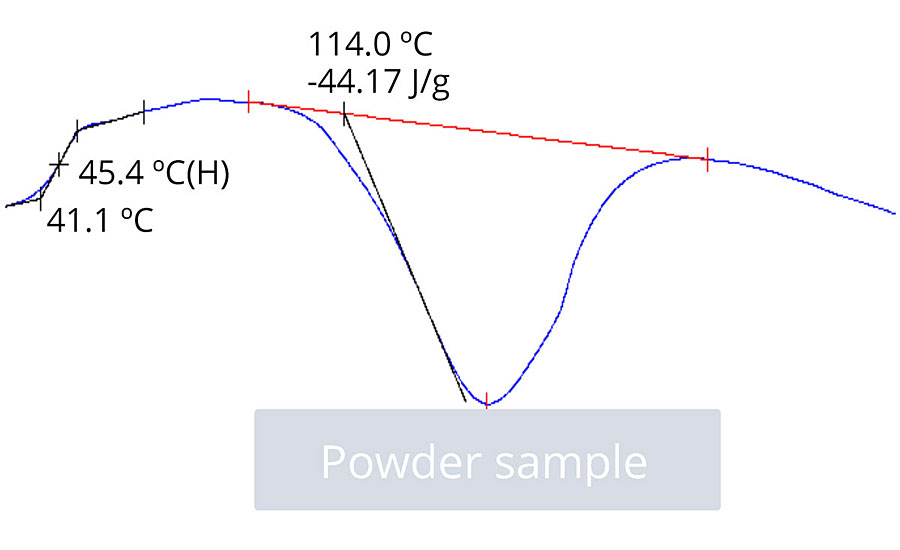

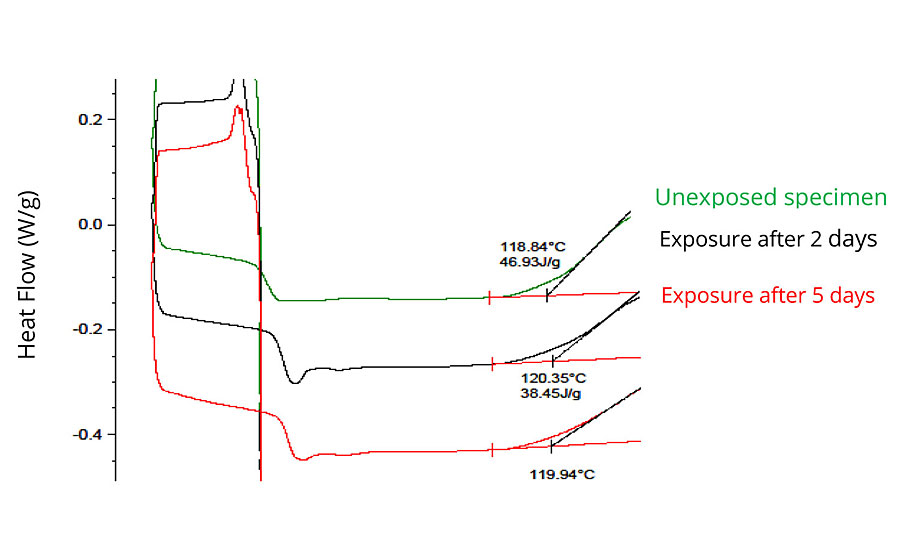

The glass transition temperature (Tg) of the unapplied formulated powder coating of the new technology is high enough to demonstrate the absence of aging and premature curing and to ensure good storage stability at standard use conditions (Figure 10). The DSC thermal analysis of the powder exposed after five days at 35 °C showed a change of 1 °C on the onset temperature versus the unexposed specimen (Figure 11). This marginal change suggests little or no chemical advancement or any handling issues after five days exposure at 35 °C.

The technology was also evaluated at room temperature (20-22 °C) after 60 days to determine any changes in performance such as appearance, gloss, chemical and mechanical resistance. It was observed that all the key properties were not negatively impacted after 60 days.

Extension of the Technology

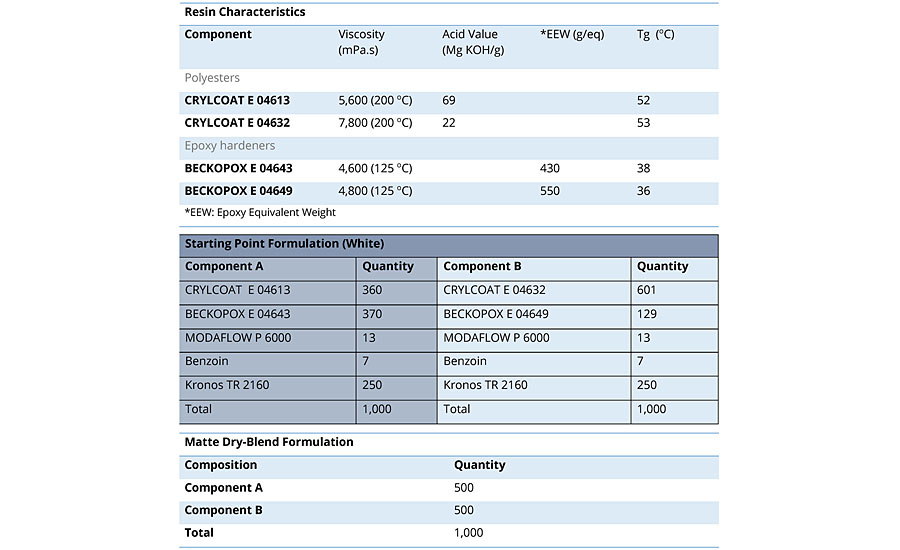

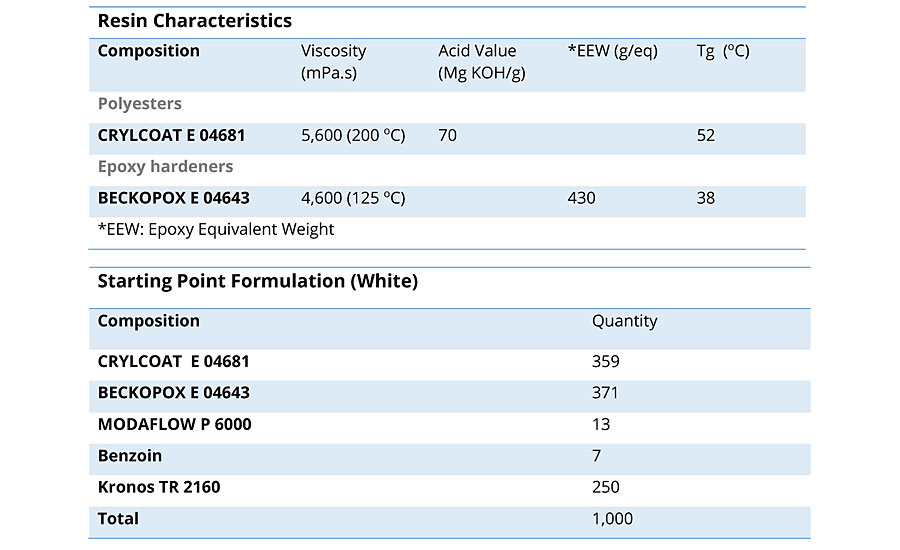

Most applications in MDF kitchen and bath cabinets specify matte finish, as it provides physical and aesthetic properties, a warm and softer appearance, is easy to clean, and makes the coated surface less visible to sunlight. In addition to the one-shot matte technology capable of achieving a gloss level of 10-20 units on a 60° gloss scale at 120 °C, there are other variations of this technology that offer high-gloss (HG) and matte-dry-blend (MDB) low-gloss finishes suitable for toilet seats and casework applications. The MDB approach uses traditional two-component paints (Component A and Component B), blended together in a 50:50 ratio to achieve the finished matte paint. Tables 9 and 10 show the starting point formulations for the high-gloss and MDB technologies. These two sister products also follow the same process parameters, and offer similar performance and handling characteristics as the one-shot-matte (OSM) technology already discussed. Refer to Table 11 for the typical coating performance characteristics of the HG and MDB systems.

Summary

The intriguing aspect of this technology is not only the excellent adhesion it has to metal but its capability to achieve matte finish at such low temperatures without compromising the outstanding chemical resistance, smoothness and manufacturing efficiency. This development furthers the allnex strategy as an innovative leader in ultra-low-bake powder coatings by expanding product offerings and widening the application window of powder coatings in areas of heat-sensitive substrates such as plastics, fiberglass and drywall.

For more information, visit www.allnex.com. You can also reach out to your regional contact below for more technical information:

Americas: cal.ezeagu@allnex.com

China: rong.xiong@allnex.com

EMEA: dietmar.fink@allnex.com

Rest of Asia: Supunnee.supeerapat@allnex.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!