Debunking Conventional Wisdom: How High-Quality TiO2 Actually Reduces Overall Paint Costs

We all know that TiO2 quality impacts appearance and performance, and that it’s also a key driver in costs. But the effect of TiO2 pigment on paint cost is more complex than simply the price of the TiO2.

Paint formulators today have more choice than ever before when it comes to the quality of pigment they select. Above all, formulators need to produce a quality paint. Whether it be applying a coating durable enough to protect a bridge, wind turbine or other piece of industrial equipment, or requiring complete opacity when painting over dark colors or stains in a residential home, formulators need to know their paints will stand up to the job. Especially as many industrial applications are demanding greater efficiency via longer-lasting, more-durable coatings that increase the length of service, quality is of critical importance.

Formulators also need to keep expenses in check. The growing availability of lower-cost TiO2 has presented many formulators with a quick way to decrease the upfront expenses when creating a paint.

Producers of these bargain pigments offer a seemingly compelling proposition to formulators in the form of lower prices. If the ultimate goal for the paint formulator is to lower overall costs, selecting lower-quality TiO2 may seem like an easy and simple way to do so.

However, the truth of the matter is that these bargain pigments are not actually a good bargain. Despite the lower upfront prices, using low-quality TiO2 can actually end up costing formulators more in the long run. When formulators take a closer look, it becomes clear that it makes more financial sense to choose higher-quality TiO2 most of the time.

Here are the three of the biggest reasons why:

Reason 1: Using Higher Quantities of Bargain TiO2 Cannot Overcome Quality Shortfalls

The quality of TiO2 used is critical in determining a paint’s total opacity, and it’s no secret that lower-quality pigments produce paints with lower levels of opacity. Many producers of bargain pigments often tell formulators that these opacity shortfalls can be overcome by simply adding in a higher quantity of lower-quality pigment. When formulators are approached with a 10% cost savings on a pigment that produces a paint with 5% less opacity, it can seem on the surface that they’re receiving a good deal.

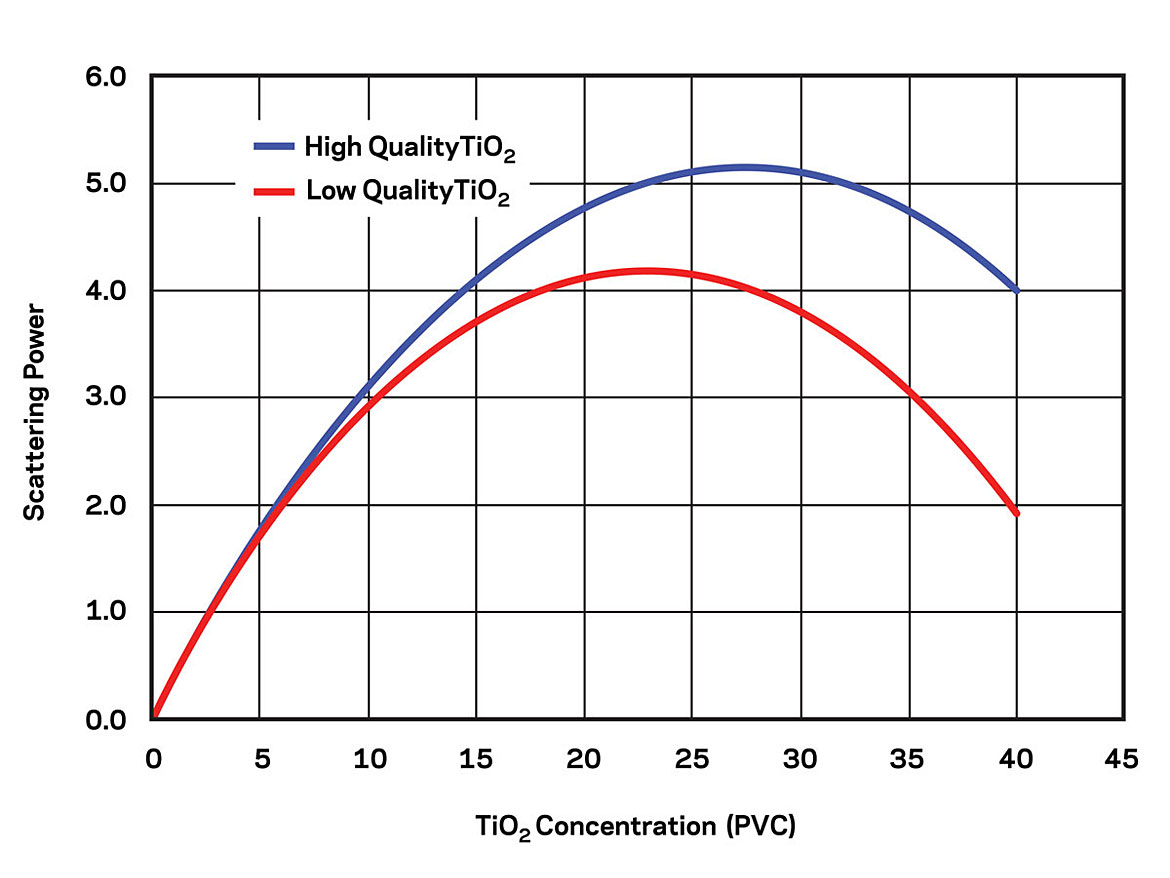

However, despite what many formulators may have been told, simply adding 5% more TiO2 does not increase light scattering by 5%, and it can be the case that using higher quantities of lower-quality TiO2 physically cannot make up the difference in opacity. In other words, there is no amount of bargain TiO2 that can achieve the same level of light scattering as high-quality TiO2. In fact, as Figure 1 demonstrates, the opacity benefit of TiO2 decreases as TiO2 levels increase, and there is an upper limit where adding too much TiO2 can even become detrimental to the overall light scattering power of the paint. In such cases, the only way to achieve complete opacity is to increase the thickness of the paint film.

These quality shortfalls eventually translate to higher overall costs. When using a paint with a lower overall light scattering power derived from low-quality TiO2, more paint will be required to cover the surface of the substrate with complete opacity. When more paint is required for a job, the formulator will need to factor in the additional resins, solvents, additives and other materials that will drive up the overall cost. In some cases, this will also require an additional coat to be applied, which adds cost to the paint user.

Most of the time, formulators can spare themselves the extra materials and energy costs required to make a greater amount of lower-quality paint, along with the headaches associated with doing so, and instead produce a higher-quality paint from the start that will end up costing less in the end.

Reason 2: When Toned For the Same Brightness, Using High-Quality TiO2 Almost Always Leads To A Less-Costly Outcome

There are two factors that contribute to a paint’s total opacity: its ability to scatter light and absorb light. Light scattering involves light rays being deviated from their straight pathway when they hit an obstacle, such as TiO2. As a result, more light bounces out of the film, and back to the eye, before penetrating deeply enough to strike the substrate. Light absorption involves light rays being absorbed and converted into energy, thus stopping the light from returning to the eye. The sum of both light scattering and light absorption is what determines a paint’s total opacity.

Low-quality TiO2 has worse light scattering than its higher-quality counterpart. Paint using low-quality TiO2 is able to overcome some of this light scattering deficiency due to the pigment’s tendency to have colored impurities, which absorb some light. Due to its higher levels of light absorption, replacing high-quality TiO2 with lower-quality TiO2 can occur with little or no change in total opacity.

However, this does not mean that the lower-quality pigment performs identically to the original pigment. Instead, we find that low-quality pigments produce paints that are slightly darker in color due to impurities. This means that while the low-quality TiO2 paint is as opaque as the high-quality TiO2 paint, it is also less bright in appearance.

If this lower brightness is acceptable for the job and the formulator is more focused on containing costs than producing the brightest white paint possible, then one must consider what would happen if the high-quality TiO2 paint was toned to the same brightness. In doing so, a significant increase in opacity can be achieved at a lower overall cost, understanding that less paint would be required to cover the surface of the substrate with complete opacity.

Exploring Brightness, Opacity and Cost Through An Example

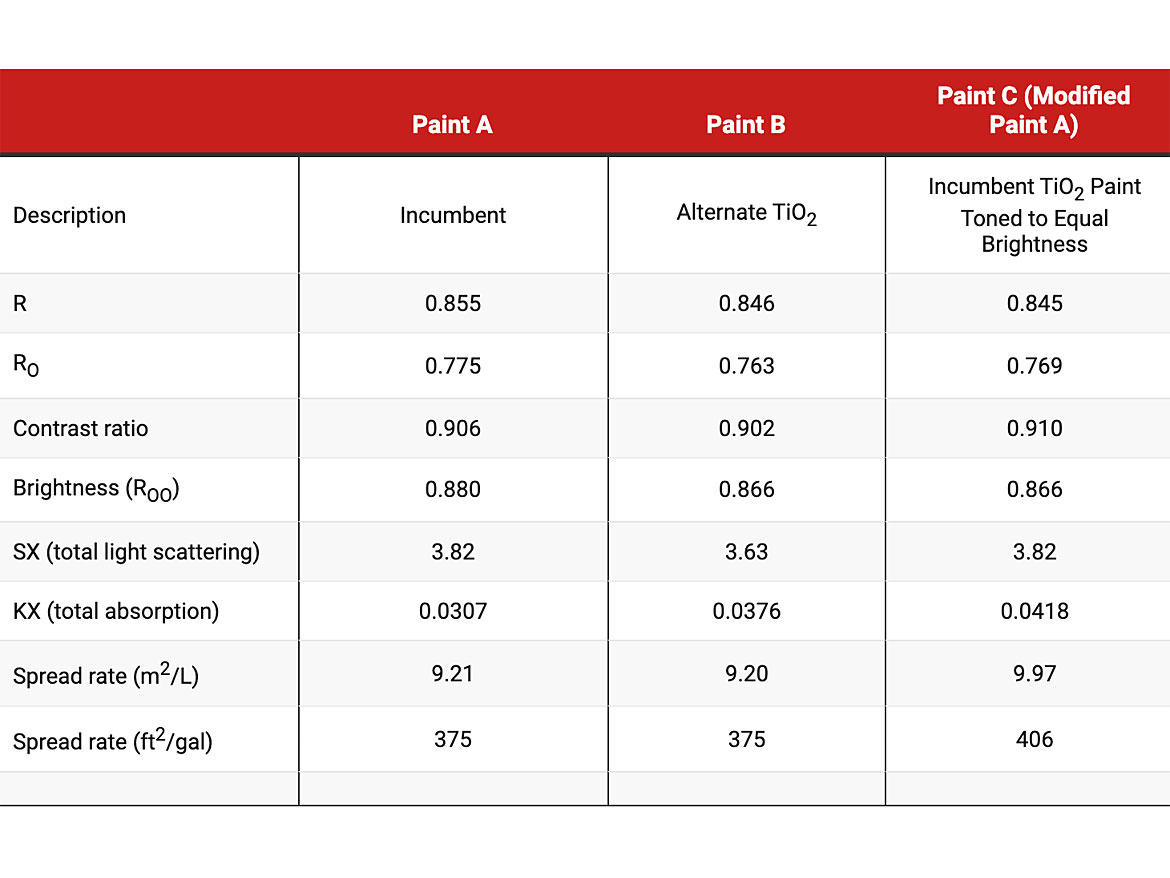

This effect is best understood through the exploration of a theoretical case study. As an example, consider the optical characteristics – brightness and opacity – of three related paints. Paint A is the incumbent paint made with a high-quality TiO2. Paint B is identical to Paint A except the TiO2 has been replaced on an equal basis with a lower-quality pigment that costs 5% less than the incumbent pigment. Drawdowns are made of both paints and the optical parameters measured on both are shown in Table 1.

As can be seen from the RꝎ and spread rate values, Paint B is less bright than Paint A but has the same opacity. The SX (total light scattering) and KX (total absorption) values calculated from the reflectance measurements confirm that this reformulation reduces light scattering but increases light absorption. We can therefore decrease the TiO2 pigment cost of the paint by 5% while maintaining opacity. Since TiO2 costs can be as high as 40% of the total raw materials cost of a paint, this exchange could decrease total ingredient costs of the paint by as much as 2%.

If the slightly lower brightness of Paint B is acceptable, then the formulator should consider Paint C, which is simply a modification of Paint A to which carbon black toner has been added to give it the same brightness as Paint B. This modification does not change the light scattering strength of the paint (SX) but increases the absorption strength (KX). Paint C differs from Paint B, then, in two important ways – stronger light scattering and stronger absorption – both of which increase opacity. As can be seen in Table 1, this increases the spread rate by over 8%.

As calculated above, Paint B provides a total ingredient cost savings of 2% compared to Paint A. However, because Paint C is 8% more opaque than Paint A (and Paint B), it decreases the cost of coverage ($/m2) by 8%. The greater savings, then, is to maintain the high-quality pigment but to tone the paint to match the lower brightness of paint made with the low-quality pigment. Looked at differently, we can say that Paint B cost less on a gallon basis but more on a coverage basis.

Reason 3: Greater Dispersibility of High-Quality TiO2 Lowers Energy Costs

Additional cost savings from using high-quality TiO2 can also be realized during paint formulation. By using the highest-quality TiO2 grades, formulators can lower the amount of dispersant needed in formulation because dispersant binds more efficiently to the surfaces of the high-quality pigment. In addition, high-quality TiO2 enables a faster, lower-energy grind because of its enhanced wettability and lower dispersant demand. On top of reduced material costs by requiring less dispersant per can, this reduction in grind time and the possible elimination of unneeded milling operations can lower the energy costs needed to produce the paint.

Through its advantages of more rapid grind-in, potentially fewer grind steps, and flexibility to be formulated at higher solids grind base, high-quality TiO2 also offers an extremely cost-effective means of increasing capacity at rate-restricted coatings manufacturing facilities.

Additionally, there are other benefits to using less dispersant that affect the quality of the paint. For example, paints that use less dispersant tend to produce films with less water sensitivity, stronger adhesion to substrates, lower hardness and greater resistance to humidity. As a result, these paints will require less touchups and can help extend the life of the underlying asset.

Calculating Total Cost is a Nuanced Equation

There are many factors to account for when selecting a TiO2 grade for paint formulation. While the lower upfront prices of bargain pigments can be extremely tempting to procurement professionals and paint formulators, most of the time it makes more financial sense to go with the higher-quality TiO2. Especially when the end goal is to produce a high-quality paint that meets the increasingly demanding requirements of today’s industrial and architectural applications, formulators can save themselves headaches and unforeseen expenses down the line by going with the higher-quality pigment from the start.

Calculating the end impact of TiO2 quality on the overall cost of the paint requires some critical thinking, but is a worthwhile exercise for paint formulators attempting to create the highest-quality paints at the lowest possible costs. For this reason, it is important to work with a TiO2 supplier that understands the unique products a formulator is producing and the various materials and steps required to create them. With this intimate knowledge, material suppliers can help formulators make the best decisions that will meet the needs of their end customers.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!