Anti-Soiling Properties and Coffee Stain Resistance

A Novel Self-Matting Coating for Automotive Interior Applications

fcafotodigital, iStock / Getty Images Plus, via Getty Images

Recently, polymer-based dull coatings became the first choice for automotive interior finishes. Self-matting, polymeric dullers ushered a new area of performance. Soft-touch haptics and non-marring behavior are now the superior properties compared to the traditional silica-based matting agents.

However, even polymeric dullers still cannot impart the matting effect simultaneously to anti-soiling properties and coffee stain resistance. Meeting the requirements from the automotive market is still a major challenge. Moreover, even with systems specialized in anti-soiling performance, coffee staining is still a key issue.

LANXESS has made research advancements in self-matting compounds with optimized formulations meeting the most stringent requirements in terms of anti-soiling properties and coffee staining. The newly developed lacquer can significantly improve both anti-soiling and coffee stain performance compared to standard self-matting lacquers. The lacquer has been tested under severe conditions. Thus, the newly developed lacquer is a state-of-the-art anti-soiling finish for automotive interior materials.

Low-gloss coatings for automotive applications based on polymer-based matting agents are already very popular, and their unique non-marring performance and soft-touch feel is unmatched. Furthermore, chemical extinction can achieve extremely low gloss levels without adding matting agents like silica. Chemical extinction refers to the synthesis of specific polymer resins via chemical reactions, taking advantage of the relationship between its structures and properties or the difference of properties within the components. The advantage is that coatings will not suffer from typical defects like brittleness, lack of abrasion, or bending issues arising from conventional dulling additives.

In addition, automotive coatings are often required to have outstanding stick-slip performance and anti-scratch properties. The most convenient way to achieve such properties is by adding a variety of additives, such as waxes, silicones, or special micro-powders. These additives, especially the group of polysiloxane additives, have been used to elevate the anti-squeak and scratch resistance of self-matting polyurethanes to a new level. However, even with the addition of such additives, other desired features like anti-soiling or coffee stain resistance are still an obstacle to overcome. Despite several attempts to solve the cleaning issue when testing automotive standards like EMPA 128/1 or EMPA 104, there are no successful solutions based on the self-matting technology available.

The commercially available products for automotive seating materials are often blends of acrylic resins and other polymers and additives in order to improve dirt pick-up. Although this method of blending can improve anti-soiling properties, it has obvious defects. Besides losing the extremely dull appearance due to mixing with glossy components, the risk of losing chemical fastness and other important properties like anti-squeak is acute.

Moreover, these blends cannot simultaneously impart the coffee stain resistance and the anti-soiling feature, so the development of a self-matting, waterborne polyurethane (PU) coating accompanied by excellent anti-soiling characteristics and coffee stain resistance is still a challenge.

Hence, how to develop a system that is able to achieve both anti-soiling and coffee stain resistance at the same time became a research hotspot.

Experimental

LANXESS has developed a unique compound based on a new self-matting PU dispersion (PUD) with excellent physical and chemical performance. This PUD is optimized to meet the latest requirements for anti-soiling and coffee stain resistance at the same time.

The compound comprises all necessary components, and just needs the addition of a crosslinker, preferably isocyanate.

The lacquer is applied by rotogravure onto the substrate (PVC, TPO or PU) with a coating weight of 10-20 g/m2 wet, and dried at 100-120 °C for 1 minute. In case of a PVC or TPO substrate, the coated material is post-embossed at 180 °C. The PU substrate already has a grain and does not need any further embossing.

Anti-Soiling Properties

The evaluation of the anti-soiling feature has two components: soiling behavior and cleanability. Generally, the test methods used are EMPA 128/1 (tested with cotton jeans, indigo/sulfur black, soiled with carbon black/olive oil) and EMPA 104 (tested with polyester/cotton (65/35), soiled with carbon black/olive oil) to evaluate the efficiency of the coating.

The soiled cloth is rubbed 1,000 times with a 1 kg weight by a Martindale testing machine over the specimen surface. Any color change of the soiled area is rated with the help of a grey scale (1 indicates intense soiling and severe change compared to unsoiled area, and 5 indicates no color change visible compared to unsoiled area) or a spectrophotometer (e.g. Konica Minolta CM-25 cG) which defines the ∆E value. Next, half of the soiled area is cleaned with a white rubbing cloth, which is soaked with a 0.5% cleaning soap solution. The cleaned area is evaluated by either grey scale or spectrophotometer.

Coffee Stain Resistance

The assessment of the coffee stain is done after approximately 1 mL of a defined mixture (instant coffee diluted in water in a certain concentration) is applied at 60-80 °C onto the specimen surface, and dried for 1 hour and 8 hours, respectively. The cleaning is performed with the help of a white rubbing cloth, which is soaked with water and soap. Any color change of the stained area is rated by the help of a grey scale (1 indicates intense staining, severe change compared to unstained area, and 5 indicates no stain visible, no change compared to unstained area) or a spectrophotometer (e.g. Konica Minolta CM-25 cG) which defines the ∆E value.

Results

Effect on Anti-Soiling Behavior

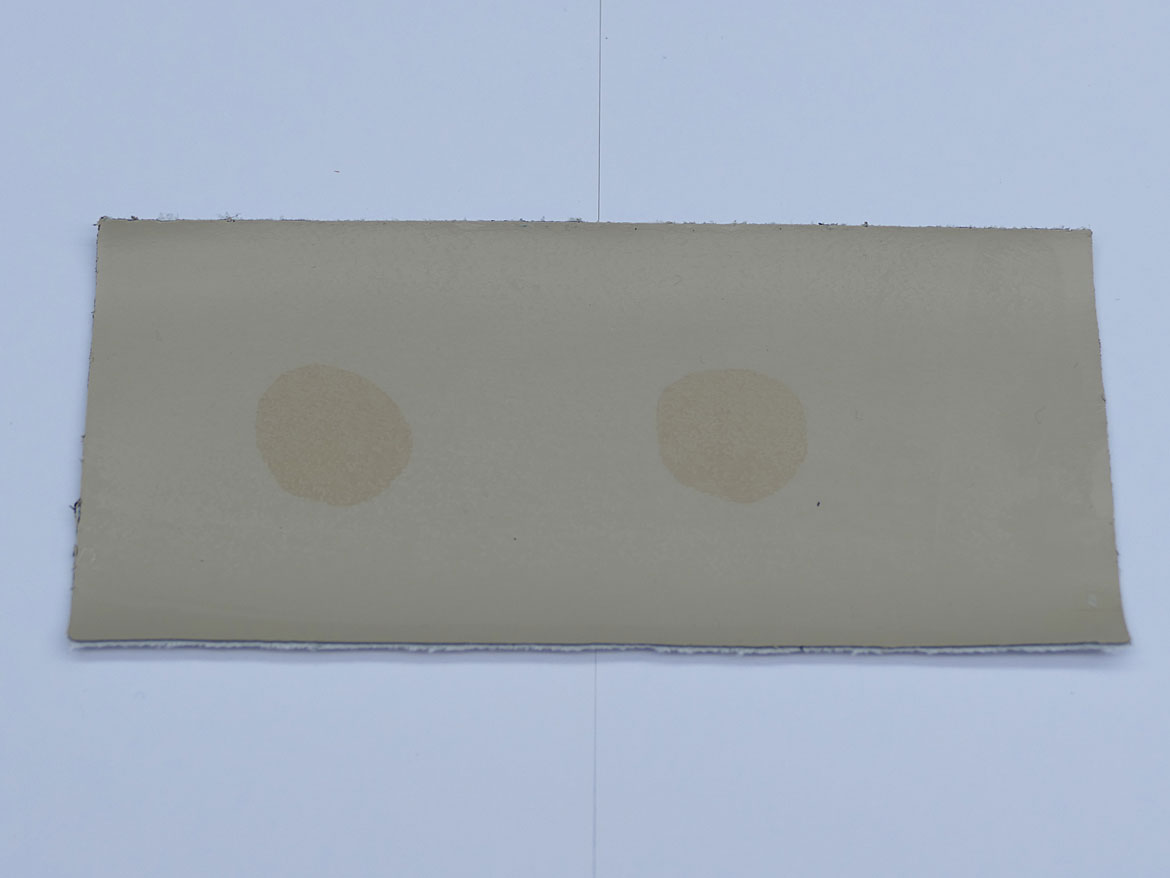

A conventional, self-matting PU for automotive interior coatings is, despite the excellent performance in matting, anti-marring, and chemical resistance, a disillusionment when it comes to anti-soiling. Looking at the results in the image below, it becomes obvious that the soiling of the specimen surface is clearly visible. This is a typical effect of finishes based on self-matting polyurethanes. Even the addition of silicones (e.g. to improve the haptics and anti-squeak properties) does not prevent the surface from being soiled. The cleanability of the surface is insufficient, which means that the dirt is not being removed.

On the other hand, finishes based on acrylic resins might show excellent dirt pick-up properties (see the image below), but have a lack in chemical resistance, matting power, and flexibility (especially cold flex resistance at -30 °C). Moreover, even when additives like silicones are added, properties like anti-squeak or required haptics cannot be obtained easily.

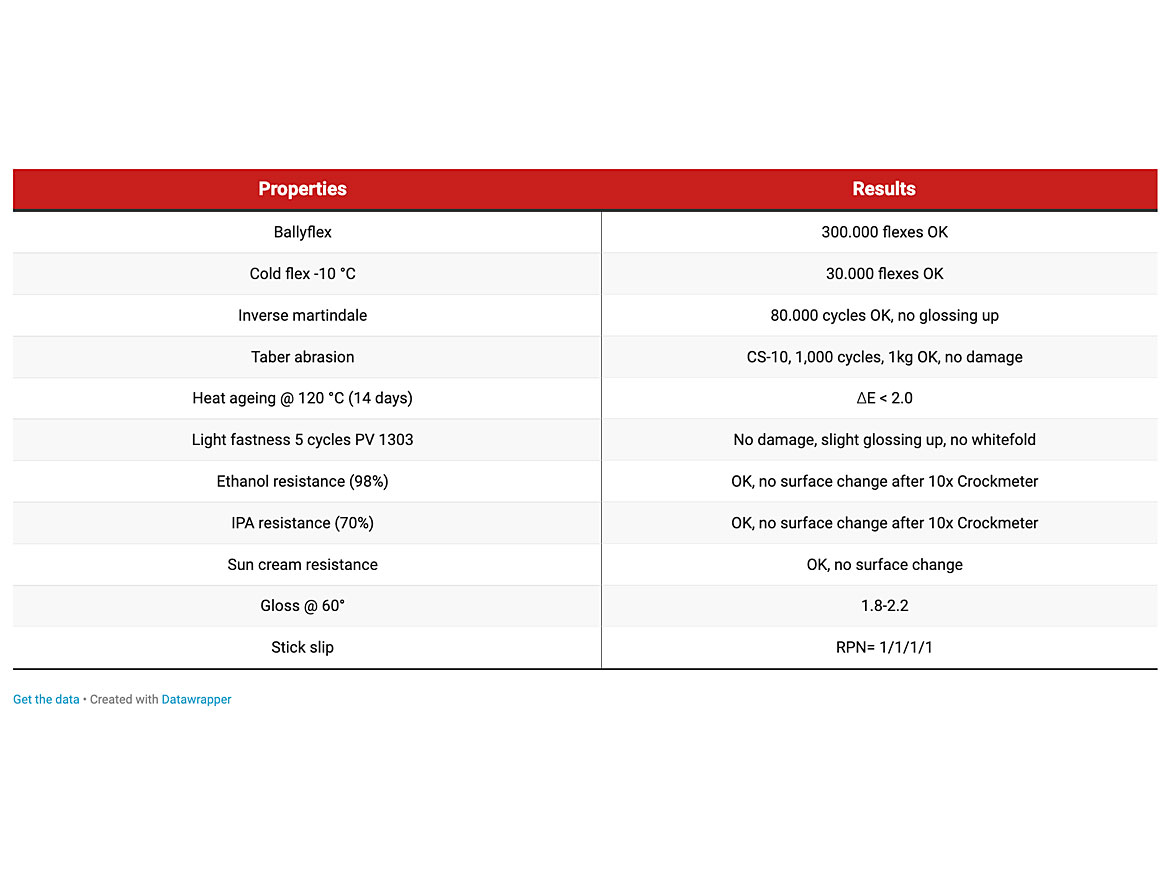

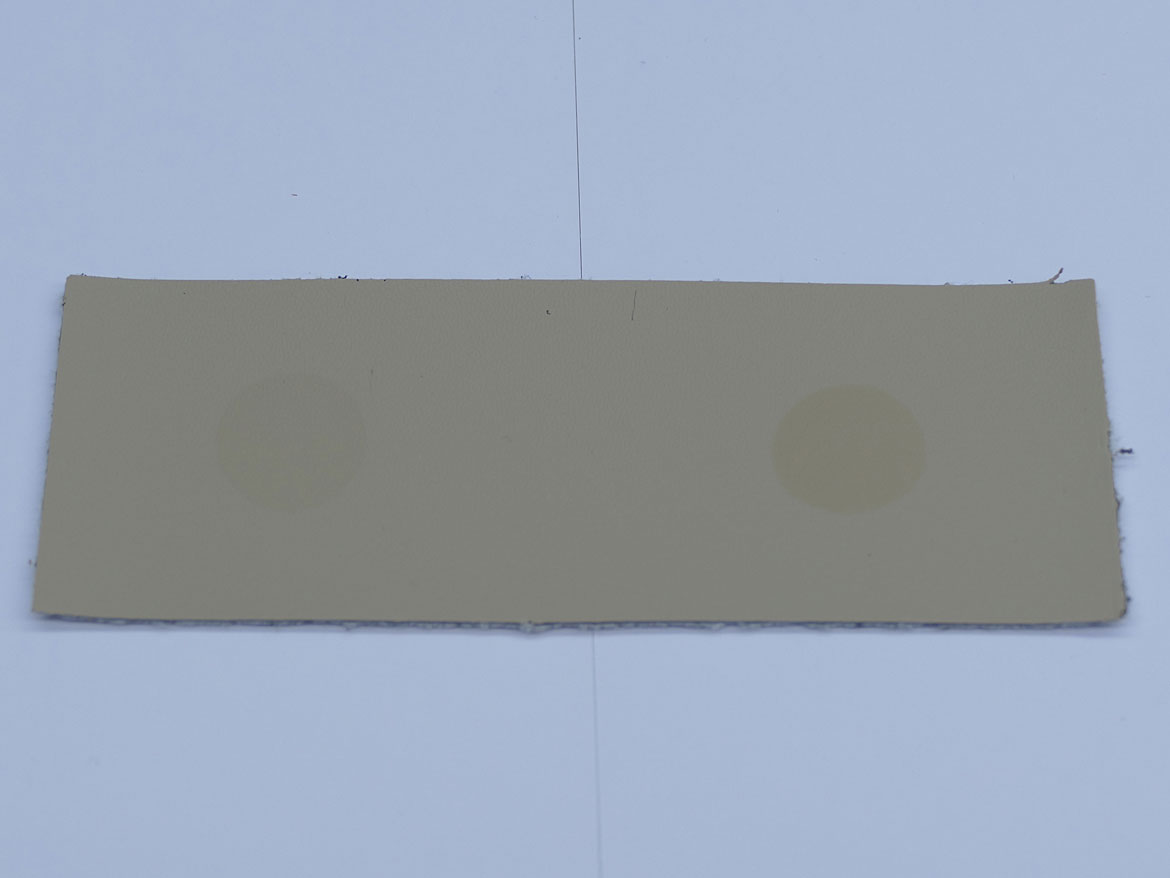

The new Pellart® lacquer system from LANXESS has the ability to combine the best of both: automotive-compliant fastnesses and easy-clean properties. This system is unique in the market. Table 1 demonstrates the performance level in terms of physical and chemical properties, and the image below demonstrates the anti-soiling behavior.

Effect on Coffee Stain Resistance

Similar effects like bad anti-soiling of conventional, self-matting PUDs are important when it comes to coffee stain resistance. They absorb coffee stains, which are impossible to clean once the coffee is dried. The poor coffee stain resistance can be seen in the image below.

Contrary to self-matting PUDs, most acrylic-based automotive finishes have outstanding coffee stain resistance (see the image below); however, as stated before, the performance on physical and chemical properties is not sufficient, besides the poor haptics and anti-squeak feature.

Combining the best of both systems, the LANXESS’ new lacquer provides excellent coffee stain resistance (see image below), and passes all other automotive requirements.

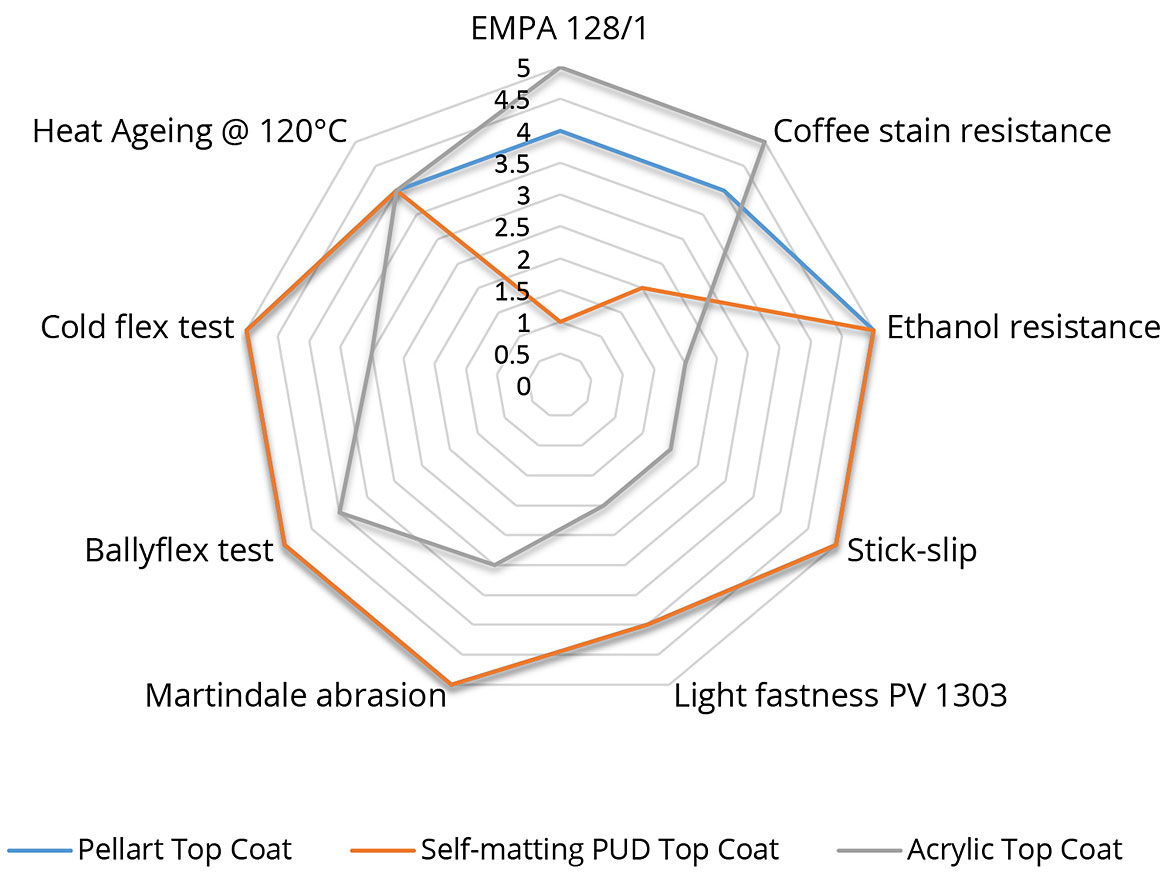

Figure 1 is a comparative overview of most used systems for automotive interior coatings.

Conclusion

In summary, both self-matting compounds and traditionally prepared coatings with classical matting agents cannot achieve the newest market requirements of having an excellent physical and chemical performance, and concurrently demonstrating good anti-soiling and coffee stain resistance.

LANXESS has developed a specific polymer-based matte coating with exceptionally good resistance to coffee stains and anti-soiling feature, respectively. This lacquer system is able to combine the advantages of a state-of-the-art self-matting resin with top-notch cleanability for automotive interior coatings.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!