Unparalleled Efficiency with Paint Shop and Final Assembly Systems

Production is underway at Togg’s new Technology Campus. Turkey’s global technology brand and first smart and connected EV manufacturer has an ambitious target for its Togg Technology Campus for electric vehicles: to be one of the most environmentally friendly plants in Europe. Dürr planned and built the paint shop as a general contractor and supplied systems for the final assembly process. NEXT.assembly, Dürr’s bundled technology spectrum for final assembly as a complete solution, was used for the first time, enabling Togg to achieve unparalleled efficiency in vehicle assembly.

175,000 smart and connected EV units are to roll off the production line annually at the Gemlik Togg Technology Campus in western Turkey by 2030. The turnkey paint shop project was awarded to Dürr in 2020, and a second order for the final assembly system followed in 2021. Together, they covered all plant engineering, application technology, and marriage, including fully automatic screwdriving stations and inspection equipment. “The pretreatment and cathodic electrocoating systems are already rated for the final expansion stage, while the plans include provision for doubling up of all other power units in the layout. Therefore, Togg can react quickly if the capacity requirements increase, for example, by adding a second oven or an entire line,” explains Bruno Welsch, CEO & President Paint and Final Assembly at Dürr Systems AG. Production started in the paint shop only recently, with the final assembly system set to be commissioned shortly.

Cutting Water, Electricity, and Heat Consumption

Togg initially opted for a lean painting process to minimize energy demand. The base coat and clear coat of the internal and external paint finish are applied in a single top coat line with integrated primer application, eliminating one drying phase. The solvent-based paints contain 30-35% more solid content than standard paints to achieve the required layer thicknesses with lower discharge rates. The EcoDryScrubber dry separation system concentrates the solvents released into the exhaust air fully automatically, and separates the overspray – saving resources in many ways. The system requires virtually no water and very little energy for air conditioning, which is usually one of the highest energy consumption processes in painting. Spray booth air recirculation of up to 95% means that heat and electricity consumption is reduced by up to 80% and 50%, respectively. This reduction also pays off economically, with energy consumption reduced by up to 60%. Togg goes well beyond the legal requirements with one additional measure to protect the environment. The Oxi.X, a regenerative thermal oxidizer (RTO) that can be operated auto thermally – in other words, without a primary energy supply for the burner – disposes of the booth exhaust air.

The EcoDryScrubber dry separation system saves 60% energy and stands for sustainable coating.

The EcoDryScrubber dry separation system saves 60% energy and stands for sustainable coating.

Latest Technology for High-Color Brilliance

Togg insists on high standards not only for environmental friendliness but also for coating quality. Next-generation Dürr robots apply the paint, including the seven-axis EcoRP E043i, which is mobile enough to paint doors from the inside and open tailgates. A unique technical feature is the EcoBell 3 atomizers, equipped with two main needles, which apply colored clear coats for particularly shiny surfaces. The second main needle eliminates the time-consuming rinse cycles previously required, reducing detergent consumption and ensuring the fastest color changes within the required cycle time.

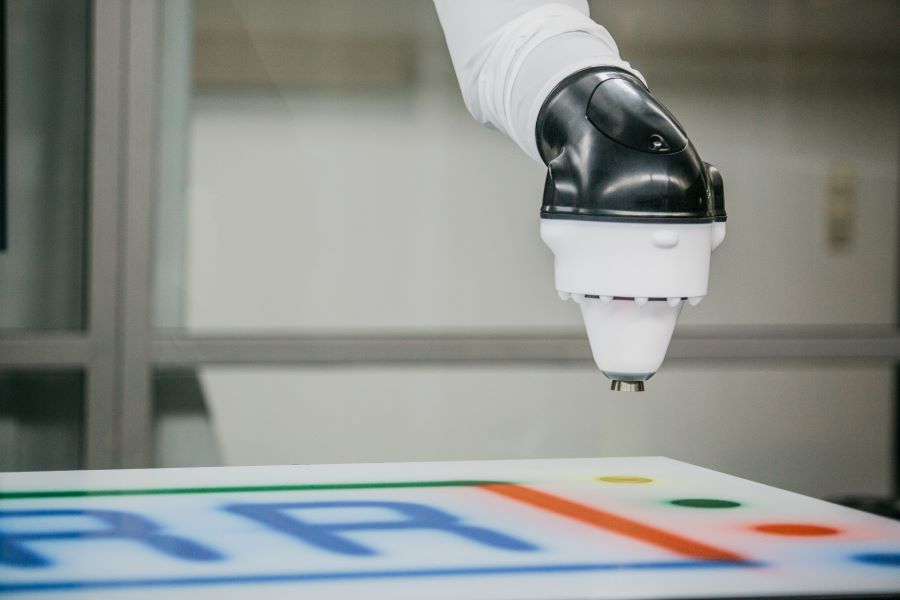

Seven-axis painting robots EcoRP E043i equipped with most recent application technology ensure highest coating quality.

Seven-axis painting robots EcoRP E043i equipped with most recent application technology ensure highest coating quality.

A New Way of Looking at Final Assembly

Togg benefits from NEXT.assembly in the final assembly area. Whereas individual components were previously the focus, the final assembly system is now considered a whole unit to make vehicle assembly as efficient as possible. NEXT.assembly bundles all of Dürr’s technology and consulting portfolio for maximum efficiency in the vehicle assembly process. The result is the most comprehensive final assembly portfolio on the market, to date. It is available as a complete solution or in individual modular parts. “Togg is the first car manufacturer to choose a complete solution from our final assembly offering. We developed a highly customized, resource-conscious solution that results in high synergy and efficiency at all levels along the whole line with precisely coordinated processes,” reports Andreas Hohmann, Vice President Consulting & NEXT.assembly.

Modern Conveyor Technology for Doors and Bodies

Dürr’s overhead conveyors ensure efficient processes. A total of 57 lightweight overhead conveyors transport the vehicle doors to a separate door pre-assembly line. Another 50 heavy overhead conveyors are provided for transporting the bodies. With the potential for future digitization, subsequent process integration or maintenance analysis tools is possible.

Window Gluing as Part of Line Tracking

One way to save material in pre-assembly is through precise dosing with the EcoShot Meter, which is suitable for almost all thick matter for sealing and gluing. The dosing unit, which is suitable for 1K and 2K applications, can also apply PU adhesives for window gluing. At Togg, these are used in the fully automatic gluing of windows and panoramic glass roofs. The automated process happens while the body is being conveyed (line tracking), making it much more efficient than the previous stop-and-go process where the vehicle conveyor had to be stopped for installation.

Flexible Marriage Process Thanks to Automation

Togg is ideally equipped for the specific marriage process for electric vehicles with a line divided into seven individual stations, including the fully automatic x-bolt screwdriving station with six individual spindles. They fasten the front-axle module, the battery, and the rear-axle module automatically with a total of 30 screwing points. A downstream manual screwdriving station fastens another 14 screwing points, which can be easily automated in the future.

Next Generation of Filling

The ProLine Cube guarantees faster and more high-quality filling for all media. As the technological core of the filling system, the fourth somac adapter generation – the ergonomic G4 blue adapter – determines the fill quality and process time.

Exact 3D-Axle Geometry Measurements

The battery-powered vehicles are inspected and aligned in two complete end-of-line systems by the wheel alignment stands x-wheel, among others. They are equipped with the new x-3Dsurface sensors. These provide 3D measurements of axle geometries and align them with an extremely high level of precision and reliability. The wheel alignment stands are combined with the headlight measurement and adjustment the systems x-light, as well as the complicated ADAS calibration systems x-DASalign, which are used for calibrating the SVC (surround view camera), FLC (forward looking camera), and FLR (forward looking radar).

The x-DASalign test stand calibrates the driver assistance systems at the end of line.

The x-DASalign test stand calibrates the driver assistance systems at the end of line.

“As the principal supplier, we work closely with Togg to meet high environmental and quality requirements,” says Bruno Welsch. The service offering is rounded out by the Turkey-based Dürr team, which will take over the ongoing servicing of the system in the future.

*All images courtesy of Dürr.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!