Powder Coating: Trends and Future

Powder coatings have emerged as a popular finishing technique for various products, ranging from industrial machinery to consumer goods. With a durable finish, environmental advantages, and versatility, powder coatings have witnessed significant growth in recent years.

The market size for powder coatings was USD 14.7 billion in 2022 and is projected to reach USD 19.9 billion by 2028, at a CAGR of 5.2% during the forecast period. Economic growth in developing countries, end-use industry expansion, investment in infrastructure, stringent environmental regulations, and growing purchasing power drive the powder coatings market.

The penetration of powder coatings is estimated to increase in the long term, and is forecasted to witness a high CAGR in the coming years. The abundant availability of raw materials, particularly in Asia Pacific, is expected to fuel the production of powder coatings. The North American and European markets are also expected to grow steadily due to the rising environmental regulations and consumer preferences for eco-friendly products. However, political and economic conditions in Western Europe and the United States, and technological factors such as difficulty applying thin coats, have restrained the market's growth. High energy consumption during powder coating application is also expected to restrain market growth.

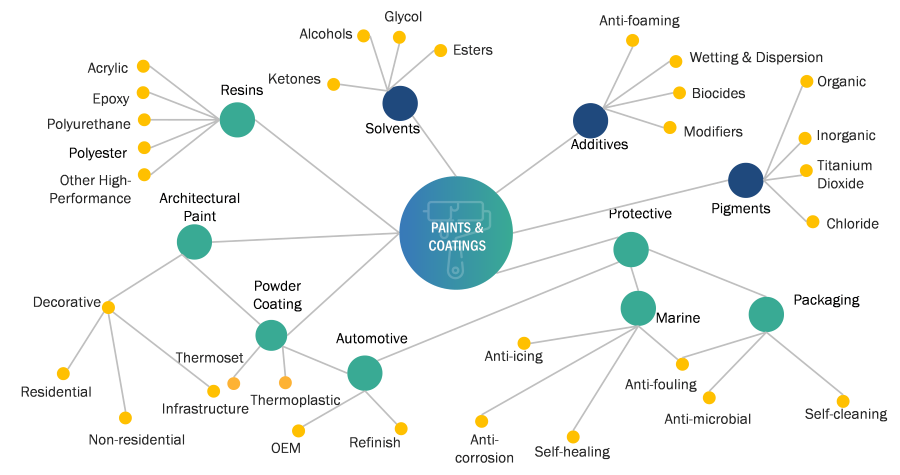

Figure 1 ǀ Market ecosystem.

Source: MarketsandMarkets

Rising Acceptance of Powder Coatings

Powder coatings have several advantages over other coatings, such as waterborne, high-solids, and solventborne coatings. Some features of powder coatings compared to other coatings are:

- Powder coatings are more durable and resistant to corrosion, abrasion, impact, weathering, and chemicals.

- Powder coatings are environmentally friendly, with low to no volatile organic compounds (VOCs) or hazardous air pollutants (HAPs) that can harm human health and the environment.

- Powder coatings are more cost-effective as they have higher transfer efficiency, lower material wastage, and lower energy consumption than other coatings.

- Powder coatings offer a wide range of colors, textures, gloss levels, and special effects that can improve coated products' aesthetic appeal and functionality.

Factors Impacting Market Demand

The rapid expansion of the powder coatings market can be attributed to advancements in materials, formulations, and application processes. The development of innovative solutions, coupled with improved equipment and application techniques, have propelled the growth of this market. Notably, the advantages of powder coatings, including enhanced durability, reduced VOC emissions, and superior resistance to corrosion, temperature, chemicals, and UV radiation, have contributed to their widespread adoption.

Global regulatory bodies, such as the Environmental Protection Agency (EPA) and Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH), have played a crucial role in driving the market growth. These entities have established stringent environmental protection regulations, creating a favorable environment for the popularity of VOC-free coating technologies like powder coatings. Despite these regulations, the market thrives due to the increasing demand from various industries.

In particular, the automotive, construction, appliance, furniture, and electronics sectors have emerged as significant contributors to the growth of the powder coatings market. The long-lasting, visually appealing, and eco-friendly finishes offered by powder coatings have positioned them as a preferred choice within these industries.

Moreover, the rising awareness of sustainable manufacturing practices has further boosted the demand for eco-friendly coating solutions. Powder coatings, with their solvent-free composition and minimal waste generation, align perfectly with the requirements of sustainable manufacturing. Consequently, manufacturers increasingly opt for powder coatings over traditional liquid coatings, driving the market growth.

The Asia Pacific region, particularly developing countries like China and India, along with countries such as Turkey, Russia, Brazil, and Saudi Arabia, present significant growth opportunities for the powder coatings market. These regions demonstrate high demand for coatings in the transportation, construction, and manufacturing sectors.

Additionally, consumer preferences for products with superior durability, aesthetic appeal, and reduced environmental impact have propelled the adoption of powder coatings. Additionally, rising disposable incomes and the demand for customized finishes have further boosted the market for powder coatings in the consumer goods sector.

Increasing Focus on Sustainable Coating Technology

Powder coatings are employed as a dry powder that flows freely. The coating is commonly applied electrostatically and cured under heat to flow and form a layer. The powder is either a thermoplastic or a thermoset polymer. It is usually used to create a tougher, harder finish than conventional paint. Powder coatings are mostly used to coat metal substrates such as home appliances, aluminium extrusions, drum hardware, automobiles, and bicycle parts.

Emerging Technologies that are Expected to Disrupt the Demand for Powder Coatings in the Future

The powder coating industry constantly advances and adapts to market needs and consumer expectations. Future disruptions that may impact the demand for powder coating are:

- Smart coatings: These can respond to external stimuli such as temperature, light, moisture, pH, etc., and change their properties accordingly. For example, self-healing coatings can heal themselves when damaged; they can repel dirt and stains. Anti-microbial coatings can prevent bacterial growth.

- Nanocoatings: These coatings are composed of nanoscale particles that can impart superior properties to the coated products, such as scratch resistance, anti-fouling, anti-corrosion, etc.

- UV-curable powder coatings: These are powder coatings that can be cured using UV light instead of heat. This can reduce the energy utilization and carbon footprint of the coating process. Moreover, UV-curable powder coatings can offer better performance and durability than conventional powder coatings.

Unveiling Lesser-Known Aspects of Powder Coatings that Could Re-Shape Market Trends and Demand

Powder coatings are applied using multiple methods, including fluidized bed, electrostatic spray, electrostatic fluidized bed, and more. Similarly, curing can be achieved through diverse energy sources like heat, ultraviolet light, and electron beams. Each method and energy source has advantages and restrictions, depending on factors such as powder chemistry, coating thickness, curing speed, and environmental considerations.

Moreover, powder coatings can be formulated with various resins, including epoxy, polyester, acrylic, polyurethane, and more. The selection of resin depends on specific application requirements and conditions, as each resin exhibits unique properties and performance characteristics.

Several Burgeoning Industries or Applications Propelling Market Demand

- Rising demand for metallic and special-effect finishes: The demand for metallic and special-effect finishes in several industries, such as automotive, consumer electronics, and home appliances, is rising. Powder coatings manufacturers are investing in research and development to create innovative new products.

- Plastics and composites: Powder coatings offer a viable solution for coating heat-sensitive plastics and composites, utilizing plasma pre-treatment to enhance adhesion, corrosion resistance, and overall appearance.

- Epoxy powder coatings: Epoxy powder coatings are extensively utilized for surface protection and hardness. Known for their toughness, flexibility, weather resistance, and cost effectiveness, epoxy powder coatings present a popular choice compared to other coating options.

Conclusion

Powder coatings have emerged as a leading finishing technique, experiencing growing market demand and notable advantages over alternative coatings. The market for powder coatings is projected to maintain steady growth, propelled by factors such as economic expansion, infrastructure investments, and strict environmental regulations. The durability, eco-friendliness, cost-effectiveness, and aesthetic adaptability of powder coatings contribute to their increasing adoption across diverse industries, including automotive and construction. The market may witness potential disruption in the future through emerging technologies like smart coatings and nanocoatings, while the demand for metallic finishes and epoxy powder coatings remains robust. In summary, powder coatings represent a versatile and sustainable finishing technique with a promising outlook for future growth and ongoing innovation.

Read the full report from MarketsandMarkets: https://www.marketsandmarkets.com/Market-Reports/powder-coatings-market-151375565.html.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!