Global Trends Represent Growth and Innovation Opportunities for the Coatings Industry

FredFroese, PhonlamaiPhoto, and imamember, iStock/Getty Images Plus, via Getty Images

In many ways, 2023 brought a feeling of “normalcy,” as the impacts of the COVID-19 pandemic and numerous supply chain disruptions receded further into history. Challenges certainly remain (including economic uncertainty and increasing regulatory pressures, among others), but opportunities abound for innovative companies in the coatings industry.

Three of the key trends we are watching include: more widespread commercialization of 3D printing, the increasing popularity of electric vehicles (EVs), and climate change-related challenges.

From the Ground Up

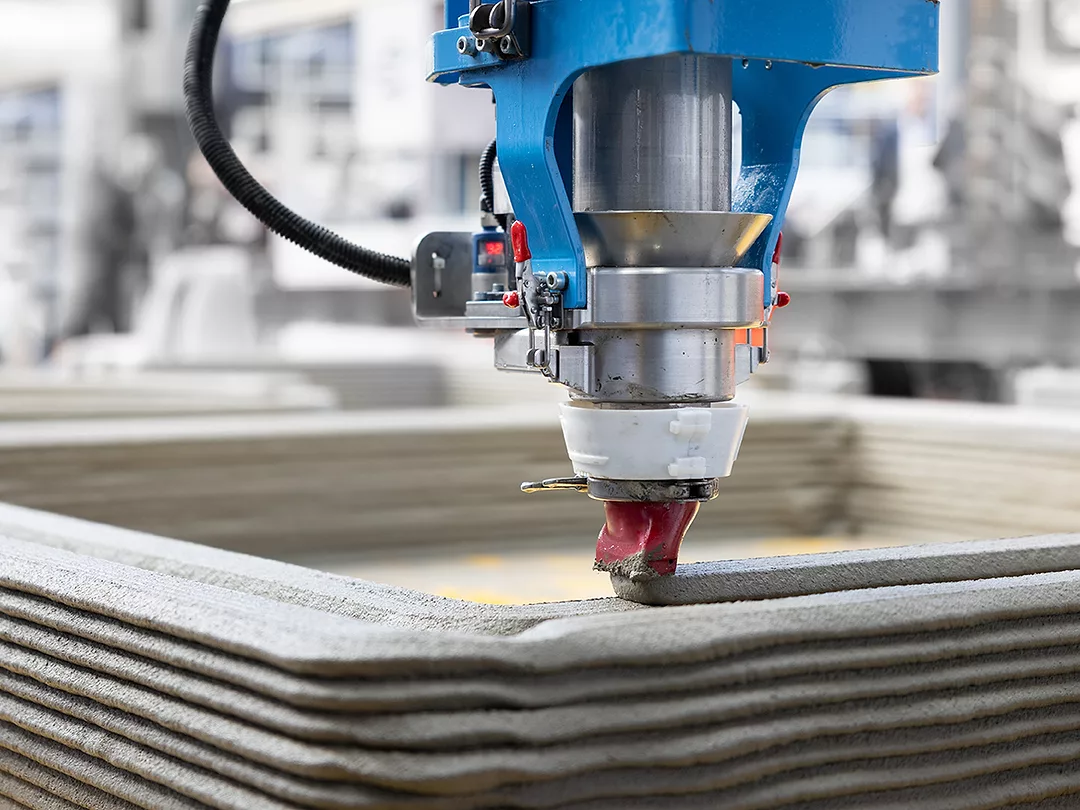

3D printing (also known as additive manufacturing) is a software-driven, computer-controlled production technique that builds parts layer by layer. In the construction sector, 3D-printed houses use concrete instead of traditional materials like wood to extrude concrete in layers, building the wall systems one layer at a time.

3D printing is attractive to the construction sector primarily due to two shortages: housing and labor. The interior and exterior wall systems for a 2,000-sq-ft house can be 3D printed in just one week, with a crew of only three people. Compared to the time and personnel required to produce a traditional wood-framed structure, 3D printing provides an opportunity to more quickly build a larger number of homes while simultaneously realizing substantial savings in resources.

In addition, 3D printing readily enables design-related innovations. New civil engineering tools assist architects and contractors in producing structures that incorporate energy efficiency from the start or include design elements like curved walls that aren’t easily accomplished with traditional construction methods and materials.

The already large global 3D construction market (estimated at $1.4 billion in 2022) is expected to see exceptionally strong growth through 2038, expanding at 80-100% CAGR to $4.2 billion. What does this mean for the coatings industry?

Concrete is much more porous than wood, and it’s also quite alkaline. Its pH is so high, best practices often dictate a waiting period of 28 days before concrete can be painted with traditional water-based paints. As a result, coating products that are tolerant to high alkalinity represent an opportunity for development and use in this market.

One route is to use mineral silicate paints. These products essentially utilize cement as a base for the paint, making them effective on cementitious substrates. Mineral silicate paints are considered durable and weather resistant.

Another option is to develop formulations with more alkaline-resistant resins, such as those like epoxies, polyurethanes, and polyaspartics that are used in concrete driveway coatings. A hybrid approach might prove effective as well, with new ways to quickly cure the cement potentially working in concert with coatings formulated specifically for 3D-printed substrates.

Many raw materials companies and coatings formulators are working on solutions in this space. Sika, for example, has invested huge resources and created a new division to focus on 3D printing in construction. In a press release, the company stated that it “has developed a multi-component system for 3D concrete printing including material supply, mixing technology, patented print head, printer system, and software control.”1

Going the Distance

Automobile manufacturers around the world have announced their plans for conversion to electric vehicles (EVs) in the next 5-10 years. Government incentives, combined with consumers’ desire to take steps to address sustainability, are driving growth in this sector.

Coatings are used for various EV components, including the battery cells and packs, power conversion systems, and electric drive systems. Estimated at $330 million in 2022, the global EV battery coatings market is expected to see a CAGR of 15% through 2028.

All EVs need fire protection, corrosion and impact protection, temperature management, and electrical shielding, though each battery pack design has its own set of requirements and challenges that need to be addressed. EV batteries depend on coatings to maintain optimal temperatures, reduce the risk of fire damage, and mitigate electrical interference.

These batteries are particularly susceptible to overheating due to arcing between metal parts. Dielectric coatings are used to prevent this arcing, with polyvinylidene fluoride (PVDF) being the preferred dielectric material.

As these materials are quite expensive, there’s a lot of opportunity here for the coatings industry to develop products that can stop a fire, prevent arcing, and keep the cost low. Due to concerns regarding PFAS (per- and polyfluoroalkyl substances), many researchers are also steering away from “fluoro” materials in their R&D efforts.

As a result, companies like Cabot, for example, are offering materials such as fumed silica and aerogel to address EV battery challenges. Silica-based materials don’t burn, and incorporation into a coating treatment could provide effective and cost-efficient protection.

Of course, EVs also represent a huge opportunity for the adhesives industry. Polymer substrate composites are being used to make lighter EVs, held together by adhesive systems on the body frame, powertrain, optical components, sensors, and radar systems.

Liquid adhesives (polyurethane, epoxy, silicone, and acrylic) represent 80% of the global EV adhesives market, which was estimated at $1.4 billion in 2022 and is expected to see an 8% CAGR through 2028. Factors for development here include thermal management, lightweighting, sustainability, safety, and cost reduction.

Cool Solutions for Hot Issues

Climate change is a driving force for innovation across myriad industries, including coatings. In urban heat islands, for example, highly concentrated buildings and roads absorb and retain heat, while a lack of greenery often limits the amount of shade. As temperatures around the world continue to increase, our cities will only become hotter.

According to the Cool Roof Rating Council, cool coatings for roofs, walls, and pavement will be vital as society explores solutions for urban heat islands.2 Due to their ability to reflect heat back into the atmosphere, installing reflective materials on buildings decreases the building’s surface temperature, as well as temperatures inside the building.

Compared to buildings with conventional roofs and walls, less air conditioning is needed to keep occupants comfortable, and buildings without air conditioning stay cooler. Cool roofs and walls also contribute to a community’s increased solar reflectance, which can actually help decrease outdoor air temperatures. The New York Times reports the island nation of Singapore is spending tremendous amounts of resources to cool itself and may provide a model for other cities.3

The global market for cool roof coatings alone was estimated to be $4.5 billion in 2022; growth is expected to remain strong, with a 7% CAGR through 2028. A cool roof is made of a material or has a coating that can lower the roof surface temperature, decreasing the amount of heat transferred into a residential or commercial building. In general, traditional roofs absorb sunlight during the day, heating the building and the surrounding air. Roofs that are lighter in color or are reflective stay cooler than roofs that absorb sunlight.

There are two ways to help cool a roof. First, a cool roof can have high solar reflectance (SR); it stays cooler by reflecting sunlight away. Second, a cool roof can have high thermal emittance (TE); it releases or emits heat (infrared radiation), so it remains cooler.

An ideal cool roof is one with both high SR and high TE. While lighter color roofs tend to have the best SR and TE, new coating and material technologies now exist for other colors that have high SR and TE.

In addition to SR, TE, and superior heat resistance, key coating properties for cool roofs include self-cleaning to maintain a clean, white surface; the ability to withstand ponding water; and elastomer-like properties to accommodate the structure’s continual shifting.

Exterior building walls are exposed to only about half the amount of sun as roofs, but they can also absorb heat. The same basic principles apply to cool walls as to cool roofs, though the coating requirements aren’t as stringent. These coatings should feature a degree of scrub-ability, as well as mold and mildew resistance.

On the other end of the spectrum, cool pavement coatings need to be exceptionally durable. These products should be resistant to hot tire pickup, ponding water, and any type of high abrasion.

Several areas of R&D are seeking to improve the effectiveness of cool coatings. Phase-change materials are particularly interesting and becoming more important as development continues. Typically micron-sized capsules, phase-change materials contain wax of a certain melting point. The wax absorbs the heat energy as it melts and then releases the energy as it cools and returns to a solid. In fact, a major roofing company, GAF, has invested in a phase-change material company, Phase Change Solutions, to secure its supply and develop new technologies.4

Climate change is also at least partly responsible for increasing numbers of natural disasters like wildfires and hurricanes. According to the “2021 LexisNexis® Home Insurance Trends Report,” nearly 15 million homes were impacted by severe natural disasters, causing $56 billion in property damage.5

The insurance industry has been tracking catastrophic weather events and the gaps between insured and uninsured coverage for many years, and the gap has been growing. In addition, an increasing number of insurance companies are refusing to offer coverage for some types of weather damage.

As Jacob Bogage wrote recently in The Washington Post, “At least five large U.S. property insurers — including Allstate, American Family, Nationwide, Erie Insurance Group, and Berkshire Hathaway — have told regulators that extreme weather patterns caused by climate change have led them to stop writing coverages in some regions, exclude protections from various weather events and raise monthly premiums and deductibles.”6

The restoration and remediation (R&R) market restores properties (residential and commercial) that have been damaged by wind, water, fire, smoke, and so on. The paint and coatings industry plays a major role in the R&R market, as specialty products are needed to address the problems seen in remediation sites. Examples include:

- Paint primers that can help mitigate stains from mold and mildew, smoke, and fire damage. Once dry, anti-microbial technology incorporated into paints can help prevent surface mildew regrowth.

- Paints that contain additives for odor control can help mitigate odors associated with mold and smoke damage.

- Safe, effective anti-microbial paints address increasing consumer awareness and concerns that mold damage can cause health issues.

- Coatings with fire-retardant properties could help prevent extreme damage to homes in drought-prone regions such as the western U.S., where fire damage has increased with the rise in wildfires.

Looking to the Future

Global megatrends represent the driving force that points to future technology growth needs and opportunities. Several megatrends, like the transition to electric vehicles and climate change, intersect to reduce the global warming potential.

Warmer environmental temperatures negatively affect the application, performance, and durability of paints and coatings. New technologies will be needed to adjust to these conditions. Keeping up with the need for housing that is safe and fire- and wind-resistant will no doubt help drive construction of 3D-printed homes.

Our likely future world will no doubt create new challenges for the paint and coatings industry. Keeping a watchful eye on global structural shifts will be essential in creating new products that address the coming needs.

To learn more, reach out to the author at vscarborough@chemquest.com, or visit https://chemquest.com.

References

1 “Sika Corporation Introduces Growing Team and Cutting-Edge Technology of 3D Concrete Printing,” June 28, 2021, https://usa.sika.com/en/construction/concrete/resource-center/news/sika-corporation-introduces-growing-team-and-cutting-edge-techno.html.

2 Cool Roof Rating Council, https://coolroofs.org.

3 Robles, P.; Holder, J.; White, J. “How to Cool Down a City,” The New York Times, September 18, 2023, https://www.nytimes.com/interactive/2023/09/18/world/asia/singapore-heat.html#:~:text=Singapore's%20prime%20minister%20has%20described,this%20isn't%20just%20uncomfortable.

4 “Phase Change Solutions Poised for Continued Growth and Innovation with Partnership and Investment from GAF,” August 2, 2022, https://www.prnewswire.com/news-releases/phase-change-solutions-poised-for-continued-growth-and-innovation-with-partnership-and-investment-from-gaf-301597758.html.

5 “2021 LexisNexis® Home Insurance Trends Report,” October 2021, https://risk.lexisnexis.com/insights-resources/white-paper/2021-home-trends-report.

6 Bogage, J. “Home insurers cut natural disasters from policies as climate risks grow,” The Washington Post, September 3, 2023, https://www.washingtonpost.com/business/2023/09/03/natural-disaster-climate-insurance.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!