New Sustainable Outdoor Wood Coating Based on a Fungus

Wood is a popular raw building material, and will be for a long time. The benefits of using wood in building practices are well known. Wood itself is a renewable resource, has natural insulation properties, captures carbon from the air, is relatively lightweight, and has clear aesthetic advantages over other building materials. This being said, wood, especially outdoors, has clear disadvantages compared other building materials such as concrete, since wood is susceptible to decay resulting from cell wall degradation by fungal degradation,4 weathering conditions like UV-damage,5 and insect infestation. Furthermore, maintaining wood is a time-consuming task consisting of sanding and de-greasing, as well as extensive cleaning.

Bio-based systems account for only a small part of the wood-protection industry. With sustainability of greater importance for consumers and businesses today, the demand for green solutions for traditional problems has been steadily growing in multiple markets. In the wood protection market, sustainable innovation has resulted in a range of available bio-based products. Bio-based means based on a biological compound, however, this term does not say anything about the quantity of the biological compound present in the final product.

Cercam has introduced a 100%-biological alternative to traditional wood protection solutions that has excellent protective abilities for outdoor wooden surfaces, as well as being a substitute for wood coatings and paints, while not being susceptible to the same extensive maintenance procedures as paints.

Market Size of Wood Protection

First, a distinction must be made between the traditional wood protection market and the bio-products wood protection markets. It is difficult to get a precise and correct estimation of the global wood protection market, as this is a broad category. Both preservatives and coatings fall under wood protection, as well as treatments to the wood itself, such as pressure or heat treatments and fire retardants. Biocides, fungicides, and insecticides are regarded as preservatives. Coatings is an umbrella term. Paints, stains, varnishes, sealers, fire retardants, water repellents, insect repellents, and UV inhibitors can be categorized as wood coatings. Due to the broad nature of the wood protection market, it is difficult to get a reliable estimation of the current overall market size. Similarly, it is difficult to get a reliable estimation of the market size of biological wood protections. However, it is logically substantially smaller than the traditional wood protection market that consists of chemical solutions.

Given that biological wood protection is a relatively new concept to the wood protection market, it will likely be accompanied by a higher growth rate than traditional preservatives and coatings. Whether bio-based products will ever amount to a similar market size depends on various factors. One is simply time, asshifting consumer demands and more focus on sustainability in professional and industrial markets will result in more sustainable alternatives for wood protections and coatings.

A Shift Towards Sustainable Products for Wood Protection

What explains the expected higher growth rate for bio-based wood protection products in comparison to traditional chemical preservatives? Mainly the growing interest in sustainable, environmentally friendly practices across various industries. As demand grows, so will the innovation markets for and supply of eco-friendly wood protection or coating solutions. Ultimately, innovation drives change, and assuming that these biologicals will be further developed and integrated in the overall wood protection market, so will its market share increase.

Regulations can further drive innovation and adaption. For example, subsidies can create an additional incentive for industries to incorporate sustainable practices and technologies, fostering positive environmental and economic outcomes.

What Other Factors Play a Role in Both the Short- and Long-Term Application of Biological Wood Protection Concepts?

As stated, regulatory support creates further incentives for both short- and long-term integration and application. Consumer awareness is an already-growing phenomenon in societies worldwide, which is reflected in a growing industry awareness. Innovation drives change, and innovation and technological advances are closely interconnected. They often influence each other in a reciprocal manner. Technological advances provide a foundation for innovation, which can help create new solutions to existing problems. Therefore, technological advances can be a catalyst for change, with a global impact. Finally, industry collaboration between researchers, businesses that operate in said industries, and regulatory bodies accelerate the development and adaptation of biological wood protection products.

What Further Influences the Expected Growth of the Biological Wood Protection Market?

One of the primary challenges with new developments like this is to demonstrate the efficacy compared to traditional chemical preservatives that have a long history of trials and regulatory approval. Wide and long-term application of biological wood protection solutions is therefore partly dependent on demonstrating that they are as effective as their chemical counterparts in protecting wood against decay, insects, and weather conditions such as UV radiation. Secondly, the cost factor of biologicals could affect their widespread adoption in the market.

Positive Properties of Chemical Wood Preservatives and Why this Dynamic is Changing

It would not make sense to elaborate only on the harmful consequences of the use of chemical substances in wood protection for two reasons. The first is that there is extensive regulation in place. This ensures that health considerations are included in the regulatory framework, which leads to ‘acceptable’ toxicity levels with ‘acceptable’ environmental consequences. Acceptable is an arbitrary term, and what is acceptable is determined by scientists and institutions that have been erected in order to advise regulatory bodies on these highly specialized topics.

The second reason involves the proven efficacy and relatively low-cost consistency and reliability in wood protective properties of chemical preservatives. These are very important aspects and ensure that wood, a sustainable building material, has a long life expectancy, protected against decay, insect infestation, and UV damage. However, these important properties of chemical preservatives are mostly relevant in a world where there are no viable alternatives for treating wooden surfaces. For decades, traditional preservatives have extended the life expectancy of wooden surfaces and structures and as a result, high-quality buildings could be built. In order to increase life expectancy, chemical solutions were applied, which prevented wood from being damaged by both biotic and abiotic stress. However, chemical wood protection has undeniable negative consequences for non-harmful insects and organisms in the ecosystem.

However, now this perspective is shifting. Innovations are taking place, and as a result, the negative environmental consequences of chemical wood protection solutions cannot be seen as unpreventable, necessary side effects of high-quality building practices. Innovations towards more-sustainable wood protection are part of a process of change, and these innovations will most likely increase in the future. With more viable alternatives to traditional wood protection products being introduced to the market, its market share will likely increase. In addition, increased consumer demand for sustainable building practices can at least be partly explained by a higher utility that consumers derive from a larger focus on sustainability. This increased utility is not only relevant for consumers, but for businesses and societies as a whole. The increased utility that a society derives from sustainable materials can at least partially be ascribed to the extensive body of research that has been conducted regarding the current environmental state of our planet, with a growing global concern for the future sustainability of our planetary ecosystem.

Biological Wood Protection Based on a Fungus

A house that has been treated with Presta BioFinish and linseed oil.

A house that has been treated with Presta BioFinish and linseed oil.

Presta BioFinish is a 100%-natural, environmentally friendly solution for wood protection. When used to protect outdoor wooden surfaces and as a staining finish, Presta BioFinish offers a long-term, sustainable alternative to traditional wood protection solutions and coatings.

The concept for this finish is based on linseed oil impregnation and a fungal-based coating.2 The fungus with protective properties for wooden surfaces is Aureobasidium pullulans, which is the most widely known species of the genus Aureobasidium. Aureobasidium produces extra-cellular polymeric substances (EPS), which enable the attachment of cells to surfaces and bio-film formation.2

By harnessing the power of a living fungus and its protective abilities for wood, an industry precedent is being set in biocide-free wood protection. When applying the combination of Aureobasidium pull. and linseed oil on wooden surfaces, besides protecting the wood against biotic or abiotic stress, it also gives the surface a black stain finish, as can be seen in the image above. This black stain finish is the result of bio-film formation.

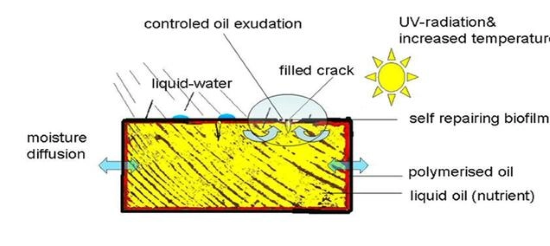

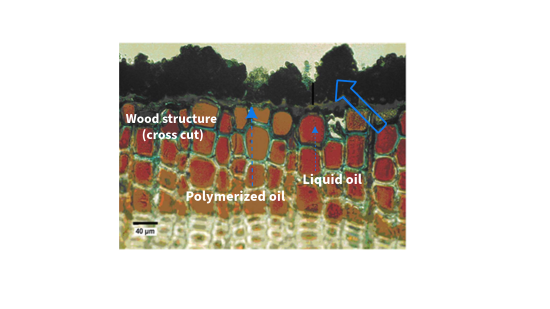

Usually, discoloring bio-films are considered negative, but in this case it can be leveraged, having a positive impact on wooden building materials.3 A pre-requisite for bio-film formation on a wooden surface is the presence of vegetable oil,1 which acts as a nutrient source and assists in the surface adhesion of microorganisms consisting of Aureobasidium pull. to wooden surfaces. The conditions that support the creation of a bio-film can be seen in Figure 1.3 A microscopic examination of the positive bio-film is shown in Figure 2.3

FIGURE 1 | Conditions supporting the creation of a bio-film.

Linseed oil stimulates the growth of Aureobasidium on surfaces and it can function as repellent for liquid water into the wood.2 The combination of linseed oil impregnation and a surface treatment with the living fungus Aureobasidium extends the service life of outdoor wood and significantly reduces maintenance costs. The linseed oil nurtures the Aureobasidium, ensuring a quick growth and stable surface of the fungus on the wood. This ensures optimal results, both in protecting the wood and aesthetics, and leads to unmatched durability.

Linseed oil stimulates the growth of Aureobasidium on surfaces and it can function as repellent for liquid water into the wood.2 The combination of linseed oil impregnation and a surface treatment with the living fungus Aureobasidium extends the service life of outdoor wood and significantly reduces maintenance costs. The linseed oil nurtures the Aureobasidium, ensuring a quick growth and stable surface of the fungus on the wood. This ensures optimal results, both in protecting the wood and aesthetics, and leads to unmatched durability.

FIGURE 2 | Bio-film (Aureobasidium pull.) on treated wood after 36-months exposure (magnification 100x).

Market Introduction of New Bio-Finish

Research into this fungus has been conducted for over 20 years, which led to the venturing of Presta BioFinish, contributing to a sustainable future, while giving the same care and protection to outdoor wood. Since its initial development, research has been an ongoing process in order to get a better understanding of optimizing the product’s protective capabilities and gathering more information on aspects such as fire behavior and application practices. Over the last 10 years, the new finish concept has been used in many projects and buildings throughout the Netherlands and other locations in the Northern Hemisphere. As of now, we have finalized setting up European distribution for industrial markets and the home and garden market.

Environmental Considerations

Traditional wood preservatives and coatings often contain heavy metals and volatile organic compounds (VOCs), resulting in a negative environmental impact and toxicity concerns. This can have long-term adverse effects on soil life, aquatic life, and bio-diversity. Biological solutions, however, are composed of and leverage natural substances; they are typically biodegradable and less or not harmful to the environment. Lower environmental impact and toxicity lead to a reduced risk of harm to ecosystems and aquatic life, or soil life due to soil contamination, when treated wood eventually enters the environment.

Application and Maintenance of Aureobasidium Pullulans

BioFinish’s stable surface prevents swelling and shrinking. In contrast to paint applications, the wooden surface does not need to be sanded, degreased, or otherwise prepared before application. This saves time and leads to very-efficient maintenance of outdoor wooden surfaces.

After application, a wooden surface holds its color for around five years and protects the wood much longer. Just one extra layer is needed for maintaining the color and extending its protection.

The Future of Wood Protection Practices

Not all of the described environmental concerns can be directed at the traditional wood protection market. Either way, within industry and across industry collaboration, paired with profitable innovation and a regulatory framework that assists industries and businesses, this type of product can provide a long-term alternative to traditional wood protection products. These alternatives will have similar protective capabilities, with reduced negative environmental impact. In the coming years, this will probably lead to refined green building standards, which combine wood protection and sustainability standards regarding toxicity levels, and certifications that prioritize environmentally friendly construction practices. This creates further space for innovations in biological wood protection solutions, fostering competition and further market development.

It is expected that the global wood protection market will keep growing, but the biological wood protection market will most likely grow at a steeper growth rate compared to traditional solutions. We hope to remain a part of this development for many years and contribute to the further development of the wood protection industry, as well as the sustainability of our ecosystem.

References

1 Filippovuch, K.; Huinink, H.; van der Ven, L.; Adan, O.C.G. Characterization of biofilm formation on wood treated with vegetable oils by color-based image interpretation method. The International Research Group on Wood Protection, 2015. https://www.irg-wp.com/irgdocs/details.php?e8e2c549-fc22-e934-7903-eac60cf79a34

2 Rensink, S.; Sailer, M.; Roukens, S.; Gerber, J; van der Mel, H.; Potgieter, K.; Spit, J.; Bulthuis, R.; Struck, C.; Bennink, M. Biofinish: A Functional Wood Surface Treatment based on Aureobasidium. The International Research Group on Wood Protection, 2020. https://www.irg-wp.com/irgdocs/details.php?3a624754-81ff-6f5f-280b-c2b67fe6693a

3 Sailer, M.; Van Nieuwenhuijzen, E. J.; Knol, W. Forming of a functional biofilm on wood surfaces. Ecological Engineering, 2010, 36(2), 163-167.

4 Schmidt, O. Wood and tree fungi - Biology, damage, protection and use, ed. Czeschlik, D., Springer-Verlag, Berlin Heidelberg, 2006.

5 Williams, R. S. Weathering of wood. In: Handbook of wood chemistry and wood composites, ed. Rowell, RM, CRC Press, 2005, 139-185.

*Images courtesy of Cercam.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.webp?height=200&t=1741213707&width=200)