The Automotive Coatings Landscape

In the dynamic landscape of automotive manufacturing, one critical aspect that often remains unseen but significantly impacts both aesthetics and functionality is automotive coatings. We have witnessed the evolution of coatings from mere protective layers to sophisticated technologies enhancing performance, sustainability, and design. In this article, we'll delve into the definition of automotive coatings, the features favored by manufacturers, recent developments, expanding applications, and future trends in this vital sector.

Defining Automotive Coatings

Automotive coatings encompass a diverse range of materials applied to vehicle surfaces to provide protection, aesthetics, and functional properties. These coatings are meticulously engineered to withstand harsh environmental conditions, resist corrosion, enhance durability, and improve appearance. They serve as a shield against UV radiation, chemicals, abrasion, and other external factors that can degrade vehicle surfaces over time.

Key Features

Durability

Automotive coatings are engineered to withstand the harsh conditions vehicles encounter daily. Whether it's exposure to UV radiation, road debris, or inclement weather, coatings provide a protective barrier that prevents corrosion, scratches, and deterioration. Advanced formulations ensure long-lasting protection, preserving the vehicle's appearance and structural integrity over time.

Aesthetic Appeal

Beyond protection, automotive coatings contribute significantly to the visual appeal of vehicles. Manufacturers invest in coatings that offer superior gloss, color vibrancy, and finish consistency, enhancing the overall aesthetics and brand image. Customization options allow for a wide range of colors, finishes, and special effects, enabling manufacturers to meet diverse consumer preferences and market demands.

Environmental Performance

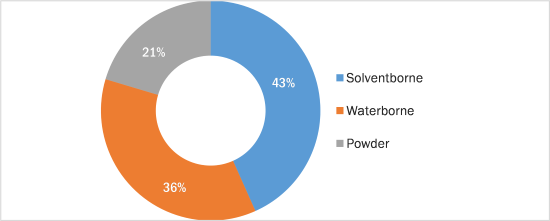

With increasing environmental awareness, automotive coatings are evolving to meet stringent regulatory requirements and sustainability standards. Waterborne coatings, for example, offer an eco-friendlier alternative to traditional solvent-based formulations, reducing volatile organic compound (VOC) emissions and minimizing environmental impact. Manufacturers prioritize coatings with low VOC content and eco-friendly ingredients, promoting sustainability throughout the vehicle's lifecycle.

Application Efficiency

Efficiency in coating application is crucial for optimizing manufacturing processes and reducing production costs. Automotive coatings are designed for easy application, with fast curing times and compatibility with automated spraying systems. Streamlined application processes ensure consistent coating thickness and coverage, improving quality control and reducing wastage.

Performance Enhancements

Automotive coatings go beyond aesthetics to enhance the performance and functionality of vehicles. Specialty coatings with properties such as scratch resistance, anti-corrosion, and thermal management contribute to improved durability, safety, and comfort. Coatings applied to functional components like engine parts and chassis provide additional protection against wear, friction, and thermal stress, prolonging their lifespan and optimizing performance.

FIGURE 1 | Stringent regulations in developed nations propel rapid growth in waterborne segment.

Recent Developments in Automotive Coatings

Recent years have witnessed remarkable advancements in automotive coating technologies, driven by the industry's pursuit of performance, sustainability, and innovation.

Nano-Ceramic Coatings

Nano-ceramic coatings represent a significant leap forward in automotive surface protection. These coatings utilize nanotechnology to create a dense, ceramic-like layer that offers unparalleled scratch resistance, UV protection, and hydrophobic properties. By forming a molecular bond with the substrate, nano-ceramic coatings provide long-lasting protection against environmental elements, preventing paint damage and preserving the vehicle's appearance.

Waterborne Formulations

With growing environmental concerns and tightening regulations, waterborne coatings have emerged as a sustainable alternative to traditional solvent-based formulations. Waterborne coatings significantly reduce volatile organic compound (VOC) emissions, minimizing environmental impact and improving air quality. Despite their lower VOC content, waterborne coatings offer excellent adhesion, durability, and color retention, making them an increasingly popular choice among automotive manufacturers committed to sustainability.

Self-Healing Coatings

Imagine a coating that can repair itself when scratched – self-healing coatings make this a reality. These coatings contain microcapsules or chemical additives that react to damage, automatically filling in scratches and restoring the surface to its original state. Self-healing coatings not only improve the appearance of vehicles but also enhance durability, reducing the need for frequent touch-ups and refinishing.

UV-Cured Coatings

UV-cured coatings revolutionize the coating application process by enabling rapid curing through ultraviolet radiation. Unlike traditional coatings that require extended drying times, UV-cured coatings cure almost instantly upon exposure to UV light, reducing production time and energy consumption. This technology also allows for precise control over curing parameters, ensuring consistent coating quality and performance.

Functional Coatings

Beyond protection and aesthetics, automotive coatings are increasingly incorporating functional properties to enhance vehicle performance. Specialty coatings with anti-corrosion, anti-fouling, and thermal management properties improve the durability, safety, and efficiency of vehicles. Coatings applied to critical components like engine parts and chassis provide additional protection against wear, corrosion, and heat, prolonging their lifespan and optimizing performance.

Smart Coatings

As vehicles become more connected and autonomous, smart coatings are poised to revolutionize the automotive industry. These coatings integrate intelligent functionalities such as self-cleaning, anti-fogging, and anti-microbial properties to enhance user experience and address emerging consumer demands. Smart coatings not only improve vehicle aesthetics but also contribute to safety, comfort, and convenience in the increasingly digitized automotive landscape.

Expanding Applications for Automotive Coatings

Beyond traditional exterior paint applications, automotive coatings are finding new and diverse applications across the vehicle.

Interior Surfaces

Automotive interiors are subjected to constant wear and tear from daily use, making them susceptible to scratches, stains, and fading. Coatings applied to interior surfaces such as dashboards, door panels, and trims provide protection against abrasion, UV radiation, and chemical spills, preserving the appearance and longevity of these components. Additionally, coatings can enhance tactile feel, imparting a luxurious and premium finish to interior surfaces, thereby enhancing the overall driving experience.

Functional Components

Beyond aesthetics, automotive coatings are increasingly applied to functional components and systems to improve performance and longevity. Critical components like engine parts, chassis, and suspension systems are prone to corrosion, wear, and thermal stress. Specialty coatings with anti-corrosion, anti-friction, and thermal management properties provide added protection, extending the lifespan of these components and optimizing vehicle performance. Moreover, coatings applied to functional surfaces reduce friction, improving efficiency and reducing energy consumption.

Advanced Driver Assistance Systems (ADAS)

The proliferation of ADAS technologies in modern vehicles has created new opportunities for automotive coatings. ADAS components such as sensors, cameras, and LiDAR systems play a crucial role in enabling autonomous driving and enhancing vehicle safety. Coatings with anti-reflective, anti-glare, and anti-fouling properties are applied to these components to optimize their performance and reliability in various driving conditions. Additionally, coatings help protect sensitive electronic components from environmental factors such as moisture, dust, and temperature fluctuations, ensuring the continued functionality of ADAS systems.

Light-Weighting Solutions

With the automotive industry's increasing focus on reducing vehicle weight to improve fuel efficiency and reduce emissions, lightweight materials such as aluminum, carbon fiber, and composites are being used extensively in vehicle construction. Automotive coatings play a crucial role in protecting these lightweight materials from corrosion, abrasion, and environmental degradation. Specialty coatings formulated for lightweight substrates offer superior adhesion, flexibility, and durability, ensuring long-term protection without compromising weight savings.

Table 1 | Automotive coatings market snapshot 2023 vs 2028.

Future Trends & Prospects

Looking ahead, several trends are poised to shape the future of automotive coatings.

Sustainable Solutions

Sustainability is no longer a choice but a necessity in the automotive industry. As regulations tighten and environmental awareness grows, automotive manufacturers are increasingly turning to sustainable coating solutions. Bio-based, recyclable, and low-emission coatings are gaining traction, aligning with the industry's commitment to reducing carbon footprint and minimizing environmental impact. Moreover, advancements in eco-friendly formulations and manufacturing processes are driving the adoption of sustainable coatings across the automotive supply chain, from raw materials to end-of-life disposal.

Smart Coatings

The integration of smart functionalities into automotive coatings represents a paradigm shift in surface technology. Smart coatings with self-healing, self-cleaning, and anti-fogging properties offer added convenience, safety, and comfort to vehicle occupants. For example, self-healing coatings can repair minor scratches and blemishes autonomously, reducing the need for costly repairs and refinishing. Similarly, self-cleaning coatings repel dirt and grime, maintaining the vehicle's appearance and reducing the frequency of car washes. As vehicles become more connected and autonomous, smart coatings will play an increasingly pivotal role in enhancing user experience and vehicle performance.

Advanced Materials

Materials science is driving innovation in automotive coatings, unlocking new possibilities for lightweight, durable, and multifunctional coatings. Advanced materials such as graphene, metamaterials, and nanocomposites offer superior mechanical properties, corrosion resistance, and thermal stability, making them ideal candidates for automotive applications. These materials enable the development of coatings with enhanced scratch resistance, UV protection, and thermal management capabilities, contributing to improved vehicle performance and longevity. Moreover, advancements in material synthesis and processing techniques are driving down costs and expanding the scalability of advanced coatings, making them more accessible to automotive manufacturers.

Digitalization and Industry 4.0

The digitalization of manufacturing processes is transforming the automotive coatings industry, enabling greater efficiency, precision, and customization. Industry 4.0 technologies such as artificial intelligence (AI), internet of things (IoT), and robotics are being integrated into coating formulation, application, and quality control processes. AI-driven formulation design accelerates the development of customized coatings tailored to specific performance requirements and environmental conditions. IoT-enabled sensors monitor coating application parameters in real-time, ensuring consistency and quality throughout the manufacturing process. Robotics and automation streamline coating application, reducing cycle times and minimizing errors. As digitalization continues to revolutionize automotive manufacturing, the adoption of digital technologies will become increasingly widespread in the coatings sector.

Enhanced Performance Coatings

The demand for coatings with enhanced performance properties continues to grow as vehicle technology advances. Specialty coatings with properties such as extreme weather resistance, anti-microbial efficacy, and thermal barrier functionality address specific challenges posed by modern vehicles. For example, coatings with anti-icing properties prevent ice buildup on vehicle surfaces, improving visibility and safety in cold climates. Similarly, coatings with anti-microbial additives inhibit the growth of bacteria and viruses, promoting a healthier interior environment for vehicle occupants. As automotive technology evolves, coatings will continue to evolve to meet the evolving needs of vehicle manufacturers and consumers alike.

Conclusion

Automotive coatings play a pivotal role in enhancing the durability, aesthetics, and functionality of vehicles, driving innovation and differentiation in the competitive automotive market. With continuous advancements in technology and evolving consumer expectations, the future of automotive coatings promises to be characterized by sustainability, performance excellence, and intelligent functionality, shaping the vehicles of tomorrow.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!