Finding a Second Life for PVB

Recycled polyvinyl butyral (rPVB)

Recycled polyvinyl butyral (rPVB)

Recycled polyvinyl butyral (rPVB)

In recent years, advancements in recycling and recovery technologies, combined with consumers demanding improved sustainability profiles of products and manufacturing processes, have given life to new and unique applications for post-consumer recycled PVB.

rPVB in Paint and Coatings

Recycled polyvinyl butyral (rPVB) is used in paint and coatings for its excellent adhesive properties, flexibility and toughness. Some key uses and benefits include:

- Adhesion: rPVB has adhesive properties, making it ideal for coatings that need to bond well to various substrates, including metals, glass and plastics.

- Flexibility: rPVB provides flexibility to coatings, which helps prevent cracking and peeling. This is particularly useful in environments where materials expand and contract with temperature changes.

- Durability: rPVB enhances the toughness of coatings, making them more resistant to impact and wear. This is essential for protective coatings in harsh environments.

- Chemical resistance: rPVB offers good resistance to chemicals, oils and solvents, making it suitable for industrial applications where such resistance is critical.

- Barrier properties: rPVB can act as a barrier to moisture and gases, which helps protect the underlying substrate from corrosion and degradation.

Applications include protective coatings, industrial coatings, architectural coatings and automotive coatings. However, challenges such as ensuring consistency — typical for any recycled material — can arise when using rPVB in paints and coatings.

Historical Background

Polyvinyl butyral (PVB) is a polymer first developed in 1927. It has many desirable uses as a polymer matrix for composite materials produced by chemical formulators and manufacturers. PVB is a clear, tough and flexible engineering thermoplastic that offers many unique properties in a variety of applications.

In the early 1900s, French chemist Édouard Bénédictus pioneered the use of PVB film to make safety glass after accidentally discovering that a glass flask coated with cellulose nitrate did not shatter when broken. Building on this discovery, he developed the first practical application of laminated safety glass by sandwiching a layer of cellulose nitrate between two sheets of glass. Later, PVB replaced cellulose nitrate as an interlayer material due to its superior properties, such as transparency, durability and resistance to yellowing. Bénédictus’s invention revolutionized the safety glass industry, leading to the widespread adoption of laminated glass in automotive, architectural and other applications.

Recovering PVB for a Second Life

Since then, the automotive industry has used windshields with PVB film to prevent dangerous shattering on impact. Today, recycling efforts for PVB film from broken windshields have gained traction as part of broader initiatives to reduce waste and promote sustainability in the automotive industry. Recycling technologies for PVB have been developed to extract and reuse the polymer material from discarded windshields, creating an almost unlimited supply of post-consumer recycled (PCR) rPVB feedstock for companies like Meridian Adhesives Group.

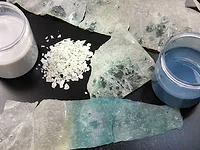

Recycling technologies for PVB involve diverting or collecting junked windshields from landfills, using glass recyclers to break the glass through specially designed machines, separating the broken glass from the PVB film, cleaning the reclaimed PVB film and converting it to chips, pellets or dispersion for distribution and use.

Each year, about 5.6% of the total vehicle population in the United States is junked. With the average car windshield measuring about 12.5 square feet, as much as 370 million square feet of PVB film is available for reclaiming and recycling each year, as opposed to being wasted in landfills. At the end of a vehicle’s useful life, approximately 1 kilogram of PVB sheet can be recycled from its windshield. Previous studies have focused on the recycling of laminated glass, especially on the effective separation of glass from PVB film. Although it has been reported that recycled PVB (rPVB) still possesses excellent mechanical properties and processing performance, there is still a large volume of rPVB that has not yet been widely destined for recycling.1

rPVB Advantages

Today, rPVB is quickly becoming a readily available post-consumer recycled product with a number of advantages. Recovery means PVB is not wasted or lost to landfills and does not require the amount of energy and processing used for virgin PVB. Like most plastic materials, the carbon footprint of rPVB is significantly lower than that of virgin PVB. It recycles with very little loss of inherent PVB characteristics and can provide a sustainably responsible, readily available and relatively affordable component replacement in polymer matrix formulations. However, virgin PVB is superior to rPVB in one respect: optical clarity. rPVB has a slight yellowish tint, making it unlikely to be used to laminate glass for windshields without expensive solvent-based cleaning processing steps.

Another area of difference between virgin and rPVB is the inherent presence of plasticizers in rPVB because it is a recycled plastic. Determining the precise nature of these plasticizers can be an expensive, lengthy process, if not impossible. This may (or may not) be an issue depending on its end use. Typically, phthalate-free plasticizers are used today for PVB plasticization, including triethylene glycol di-(2-ethyl hexanoate) (3GO), tetraethylene glycol di-n-heptanoate (TEGH), dibutyl sebacate (DBS), dihexyl adipate (DHA), dioctyl adipate (DOA) and others.2

Use of Waterborne Dispersion in Paint, Coatings and Dispersions

A waterborne dispersion is an excellent use of rPVB. By suspending rPVB in water, it can be used as a formula matrix component for various applications. Meridian Adhesives Group pioneered the use of rPVB water-based dispersions for the flooring industry and is developing more applications in other industries. Meridian’s technical teams work with customers to enhance product performance and characteristics while boosting sustainability, regulatory and certification compliance.

One of Meridian’s standard rPVB dispersion details includes:

- Solids: 47–49% (by weight)

- pH: 9.5–10.5

- Viscosity: <1,500 cps

- Specific gravity: 1.01

- Weight per gallon: 8.40 lb/gal

- Particle charge: anionic

- Readily available

Sustainability details for rPVB waterborne dispersions are as follows:

- Total recycled content by weight: ~46% (wet-as-supplied)

- Recycled content sourced from post-consumer polymer (sourced from post-consumer PVB from windshield/safety glass recycling partners)

- ~2 pounds of wet dispersion diverts a windshield from the landfill

- Largely decoupled from oil and gas

rPVB Applications

As a waterborne dispersion, rPVB can create sustainable paints, coatings and inks that are safe, nontoxic and greener. Additionally, rPVB can enhance textile coatings, contributing to durability, abrasion resistance, sound dampening and UV resistance. In every case, an rPVB waterborne dispersion can replace various styrene, polyurethanes, epoxies or acrylics with a sustainably superior, low-toxic and recyclable alternative that is preferred by consumers.

Here are just a few examples:

As a Textile Coating

“rPVB was investigated as a material for yarn coating. Polyester and polyamide mono- and multifilament yarns were coated continuously with solely a polymer dispersion and with mixtures of a crosslinking agent and polymer dispersion. Crosslinked rPVB coatings showed enhanced properties toward abrasion and chemical resistance. Coatings without the crosslinking agent showed diminished abrasion resistance and could be washed off with ethanol.”³

As a Backcoat Ingredient to Assemble and Protect Carpets

Meridian Adhesives Group has developed and employed a waterborne rPVB dispersion for customers in search of unique solutions in the flooring industry. For the commercial carpet tile industry, tile edges can be problematic, with fibers that can unravel. Manufacturers may also want to offer a more sustainable specification for architects. rPVB can satisfy both needs by keeping carpet yarns in place and contributing to LEED points. For marine carpet, lying flat and resisting weather and UV punishment without degradation is important. The use of rPVB accomplishes both. For nylon carpet used in indoor/outdoor installations, rPVB resists the usual decolorization that occurs from prolonged exposure to sunlight and heat.

Case Study: PC-9000 Tufted Carpet Backing for Automobile Interiors

An automaker wanted a tough, durable interior tufted carpet for its line of minivans that would resist the delamination of carpet fibers from day-to-day use. The carpet manufacturer chose to coat the carpet’s secondary backing with Meridian rPVB dispersion PC-9000 to hold the fibers securely in place while also fitting snugly to the vehicle’s interior upholstery design.

For this coating, the base dispersion is comprised of recycled, plasticized polyvinyl butyral in water. The dry compound contains 11–13% post-consumer recycled content. The film formed from PC-9000 is comparable to carboxylated SBR compounds and exhibits better water resistance. Windshield PVB is heat- and UV-resistant and those properties carry over to the recycled dispersion. This compound is a nonchlorinated vinyl that remains totally amorphous even in the cured state. This allows coated materials to lay flat on uneven surfaces. Formulators must be careful not to add ingredients with a pH below 7 because acids will coagulate the compound. The technical staff at Meridian can assist with customer formulation or create a ready-to-use product for specific needs.

rPVB Properties

- Solids, %: 71.0–74.0

- pH: 9–10

- Viscosity (cP): 6,000–8,000

- Specific gravity: 1.44

- Weight per gallon (lbs.): 11.5–12.5

PC-9000 is a fully compounded carpet coating formula containing calcium carbonate filler, a froth aid package and other components. Due to the presence of these additional components, PC-9000’s recycled content is 11–13%. PC-9000 is the trade name of the manufacturer for this particular use.

Summary

Awareness of sustainable products and the care manufacturers take to source responsibly made components are growing among a new generation of product developers and consumers. rPVB is a perfect example of reusing and repurposing a component without depleting or polluting resources. More case studies are being written every day for this remarkable material.

For more information, contact Meridian's Polycom brand at 706-271-0466.

References

1 Carmona-Cervantes, I.A.; Campos-Silva, I.; Figueroa-López, U.; Guevara-Morales, A. “Effect of recycled polyvinyl butyral (rPVB) addition on the tribological performance of glass-fiber reinforced polyamide (PAGF) during reciprocating sliding wear conditions.” Polymer, 2023.

2 Brendgen, R.; Graßmann, C.; Grethe, T.; Mahltig, B. “Coatings with recycled polyvinyl butyral on polyester and polyamide mono- and multifilament yarns.” ResearchGate, 2023.

3 Ude, M.; Ashraf-Khorassani, M.; Taylor, L.T. “Supercritical fluid extraction of plasticizers in poly(vinyl butyral) (PVB) and analysis by supercritical fluid chromatography.” Chromatographia, vol. 55, 2002, pp. 743–748.

4 Maŕin, A.P.; Tatarenko, L.A.; Shlyapnikov, Y.A. “Solubility of antioxidants in poly(vinyl butyral).” Polymer Degradation and Stability, vol. 62, 1998, pp. 507–511.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!