Carboxylic-Functional Ultramatte Binders

A Breakthrough in Two-Component Coating Technology

Courtesy of Stahl

The coatings industry is constantly evolving to meet the increasing demands for high-performance, environmentally friendly products. One of the latest advancements in this field is the development of a new carboxylic-functional ultramatte binder for two-component (2K) systems, designed to offer high-performance coatings with enhanced chemical and mechanical resistances, transparency and self-healing properties. This article provides a comprehensive overview of this innovative coating system, exploring its composition, performance and benefits compared to traditional silica-based matting agents.

Introduction to Ultramatte Coatings

Ultramatte coatings are gaining popularity due to their aesthetic appeal and functional benefits, including a nonreflective surface that enhances the visual quality of various substrates. These coatings are widely used in automotive, furniture and consumer electronics applications. However, achieving a durable ultramatte finish while complying with stringent health, safety and environmental regulations remains a challenge.

Market Needs and Challenges

The coatings industry faces increasing regulatory scrutiny, with requirements related to labeling, risk phrases, VOC emissions and carbon footprint reduction. Additionally, there is a growing demand for superior scratch resistance, chemical resistance and self-healing properties.

Innovative Solution: Carboxylic-Functional Ultramatte Binder

To address these challenges, a new carboxylic-functional ultramatte binder has been developed for 2K systems. When crosslinked with a carbodiimide, this binder enables high-performance coatings that meet modern market needs. The system is based on inherently matte polyurethane dispersions (PUDs) enhanced with optimized carboxylic functionality, allowing for effective crosslinking and improved durability.

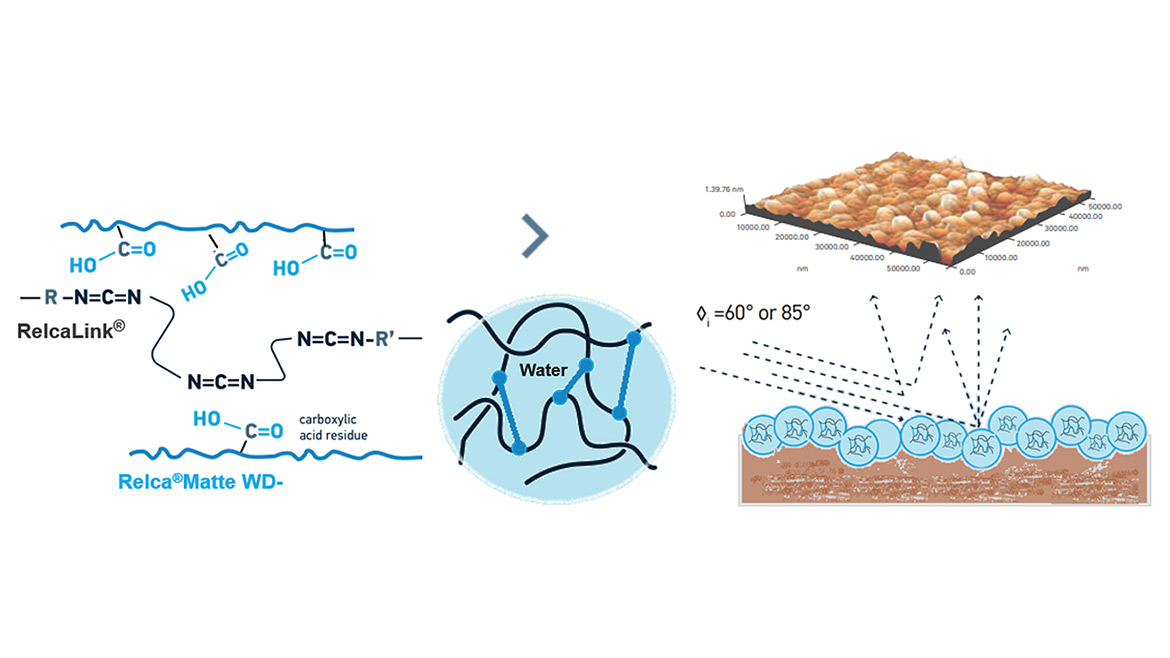

Composition and Mechanism

This innovative ultramatte coating system consists of a matte binder and a multifunctional carbodiimide crosslinker (Figure 1). The binder is designed with specific particle shape and size distribution, which controls surface roughness at the microscale during film drying. This micro-roughness diffuses light, resulting in a matte appearance. The crosslinker enhances the physical and chemical resistance of the coating, ensuring long-term performance.

Comparative Performance Testing

Extensive testing was conducted to compare the new ultramatte coating system with a standard PUD + silica-based matting agent formulation. The key performance indicators included:

- Chemical and Stain Resistance: The new system demonstrated superior resistance to various chemicals and stains, maintaining integrity and appearance after prolonged exposure.

- Scratch Resistance: Using a diamond tip scratch test, the new coating showed higher resistance to scratching compared to traditional systems.

- Transparency: The new ultramatte coating maintained excellent transparency, ensuring that the underlying substrate's appearance was not compromised.

- Blocking Resistance: The coating exhibited good blocking resistance, preventing surfaces from sticking together under pressure.

- Taber Abrasion: The new system showed lower weight loss in abrasion tests, indicating higher resistance to wear.

- Rub Resistance: The coating maintained its gloss and appearance even after multiple rubs, demonstrating high rub resistance.

- Self-Healing Properties: One of the standout features of the new system is its self-healing ability. After being subjected to mechanical damage, the coating can recover its original gloss and appearance over time.

Detailed Test Results

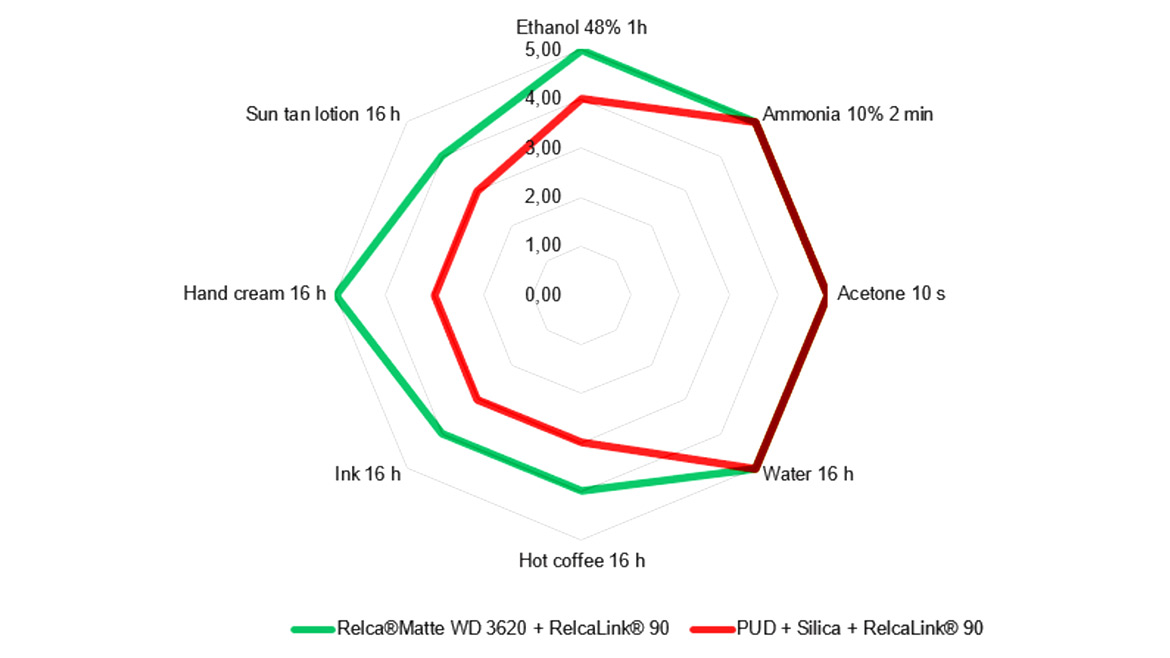

Chemical and Stain Resistance

The chemical and stain resistance tests involved applying various substances such as ethanol, ammonia, acetone, water, hot coffee, ink, hand cream and sunscreen to the coated surface. The new ultramatte system showed minimal changes in appearance and maintained its integrity, outperforming traditional PUD and silica-based systems (Figure 2).

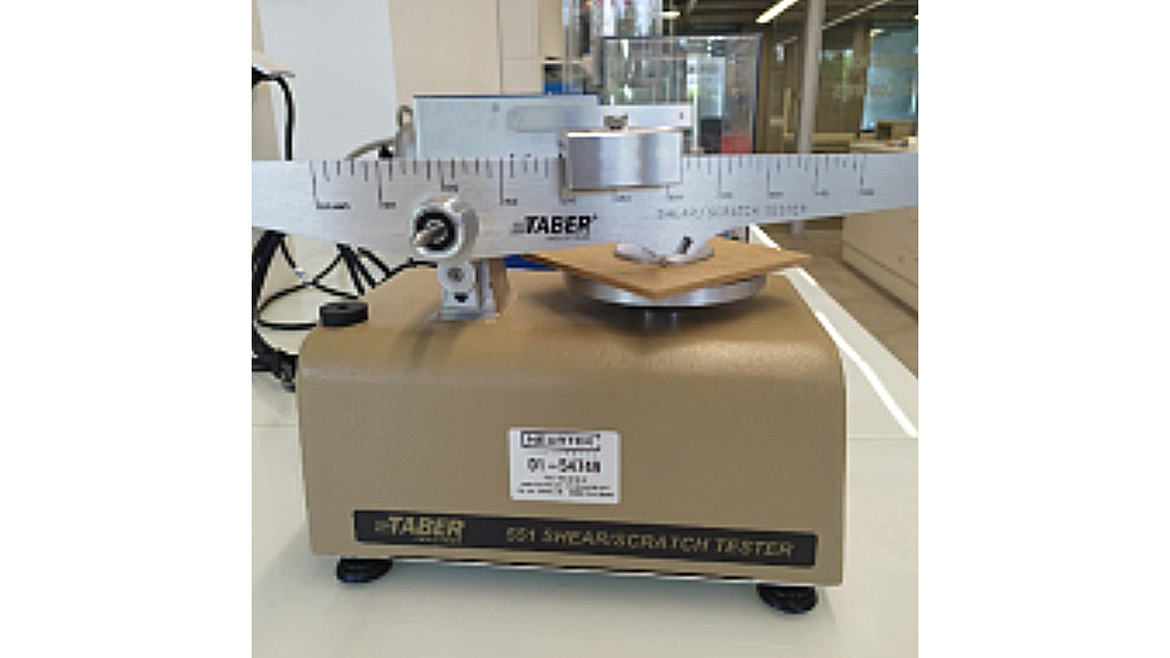

Scratch Resistance

Scratch resistance was evaluated using a diamond tip to apply a variable force to the coating. The minimum force that left a visible mark was recorded. The new ultramatte system required a higher force to leave a mark, indicating superior scratch resistance compared to traditional systems (Figure 3).

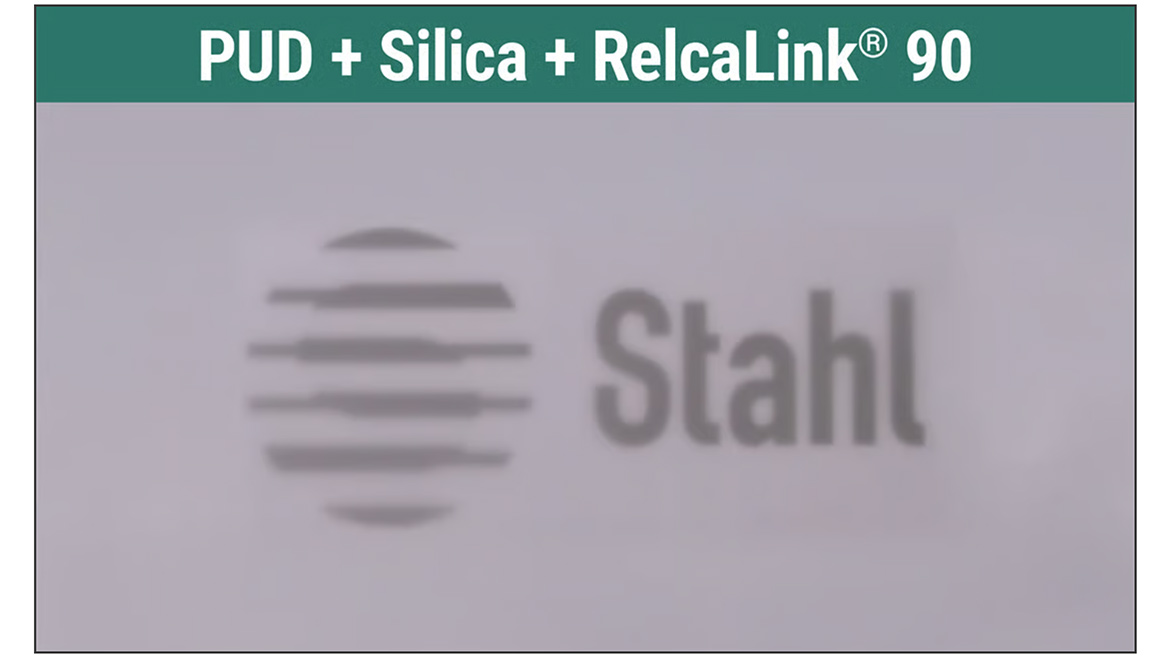

Transparency

Transparency tests involved applying the coating to a substrate and visually evaluating the clarity of an image placed behind the coated surface. The new ultramatte system maintained excellent transparency, ensuring that the underlying substrate's appearance was not compromised (Figure 4).

Blocking Resistance

Blocking resistance tests involved applying the coating to a substrate, drying it and placing two coated surfaces face-to-face under pressure. The force required to separate the surfaces was measured. The new ultramatte system exhibited good blocking resistance, preventing surfaces from sticking together under pressure (Table 1).

Taber Abrasion

Abrasion resistance was tested using Taber CS17 wheels with a 1 kg weight for 1,000 cycles. The weight loss after the test was measured. The new ultramatte system showed lower weight loss, indicating higher resistance to wear compared to traditional systems (Figure 5).

Rub Resistance

Rub resistance tests involved applying the coating to a substrate and subjecting it to multiple rubs using a felt pad, with gloss measurements recorded before and after. The new ultramatte system maintained its gloss and appearance even after multiple rubs, demonstrating high rub resistance (Figure 6).

Self-Healing Properties

Self-healing properties were evaluated by measuring the gloss change and recovery after subjecting the coating to mechanical damage. The new ultramatte system showed significant gloss recovery over time, indicating its self-healing ability (Table 2).

Environmental and Safety Benefits

In addition to its performance advantages, the new ultramatte coating system is designed to be environmentally friendly. It has a low-VOC content and is free from hazardous labels, making it safer for both manufacturers and end users. The optimized carboxylic functionality also contributes to a lower carbon footprint, aligning with global sustainability goals.

Applications and Market Potential

This innovative ultramatte coating system is well-suited for various industries, including:

- Automotive: Providing a durable, aesthetically pleasing finish for car interiors and exteriors.

- Furniture: Enhancing the appearance and durability of wooden furniture.

- Consumer Electronics: Offering a sleek, non-reflective finish for electronic devices.

Given its performance and environmental benefits, this coating has significant market potential, addressing the demand for high-quality matte finishes while meeting regulatory requirements.

Conclusion

The development of carboxylic-functional ultramatte binders marks a significant advancement in 2K coatings. This innovative technology provides high scratch resistance, self-healing properties and environmental compliance

As the coatings industry evolves, sustainable, high-performance solutions will play a critical role in shaping the future. This new ultramatte system offers a comprehensive solution, meeting market needs for durability, aesthetics and eco-friendliness.

*All images and graphics courtesy of Stahl.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!