Sponsored Content

Next-Gen Matte Performance

Dow Reinvents Interior Coating Durability

Image courtesy of Dow.

Background

For interior wall paint applications, consumers tend to prefer lower sheen options, ranging from flat to eggshell, to hide imperfections in the walls and for a more pleasing visual aesthetic. Typically, flatter paints are less durable than higher sheen paints due to the higher amount of extender pigment at the film surface. In higher sheen coatings, there is more resin at the surface, bringing improved durability properties. While flat sheen paints address consumer aesthetic preferences, the durability properties — such as stain, scrub and burnish resistance —are usually lacking. Extender pigments also pose significant challenges in bulk handling due to their dry powder form, necessitating dispersion processes, which can add extra steps and complexity to the formulating process. Consequently, the coatings industry needs innovative solutions that not only enhance the performance of coatings but also improve manufacturing efficiency and simplification. Dow’s Durable Matte Technology solutions offer matting without compromising durability and are the key to successfully addressing the full range of consumer expectations.

Dow Coating Materials strives to lead the coatings industry through innovation, consistently introducing groundbreaking technologies. In addition to the RHOPLEX™ and EVOQUE™ acrylic resin portfolio — which brings exceptional durability, resistance properties and hiding to interior, exterior and specialty coatings formulations for the last several decades — our team has recently been developing the first generation of Durable Matte Technology platform products. This portfolio will be a distinct class of self-matting resins and polymeric matting extenders. OPTI-MATT™ 2300C Emulsion and Experimental (EXP) MT-8 polymeric extender are the first products from this technology platform in North America, offering low-sheen aesthetics with high-sheen durability properties, and are a continued focus for future innovation development.

OPTI-MATT™ 2300C 100% Acrylic Emulsion Polymer

This innovative binder technology is specifically designed for architectural interior wall coatings and allows for the formulation of low-sheen paints without the need for traditional matting extender pigments. OPTI-MATT™ 2300C Emulsion supports the production of matte paints with exceptional scuff and mar resistance, resistance to color transfer and can be blended with other binders to achieve a wider sheen range. Additionally, OPTI-MATT™ 2300C helps enable the production of paints using all liquid materials, eliminating the need for the energy-intensive high-speed dispersion of dry pigments.

Experimental MT-8 Emulsion Polymer Pigment

Experimental (EXP) MT-8 is an innovative polymeric pigment supplied in emulsion form and designed for controlling the gloss of specialty coatings, such as clear matte wood coatings and beyond. EXP MT-8 helps enable durable coating formulations with enhanced scuff and mar resistance, solvent resistance, stain resistance and exceptional resistance to color transfer when tinted — without the use of traditional extender pigments. EXP MT-8 can be combined with the formulator’s binder of choice for interior specialty and wall applications, supporting the development of formulations tailored to address specific end-use properties. EXP MT-8 also supports formulation using all liquid materials, eliminating the need for the energy-intensive high-speed dispersion of dry pigments.

The physical properties of OPTI-MATT™ 2300C Emulsion and EXP MT-8 are provided in Table 1.

OPTI-MATT™ 2300C Emulsion in Architectural Coatings

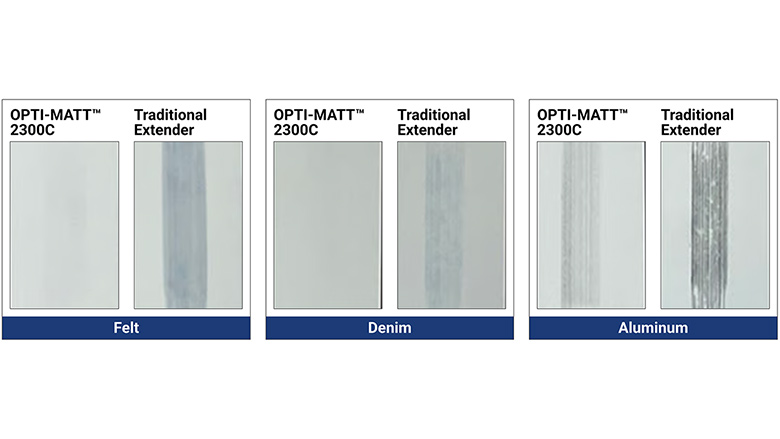

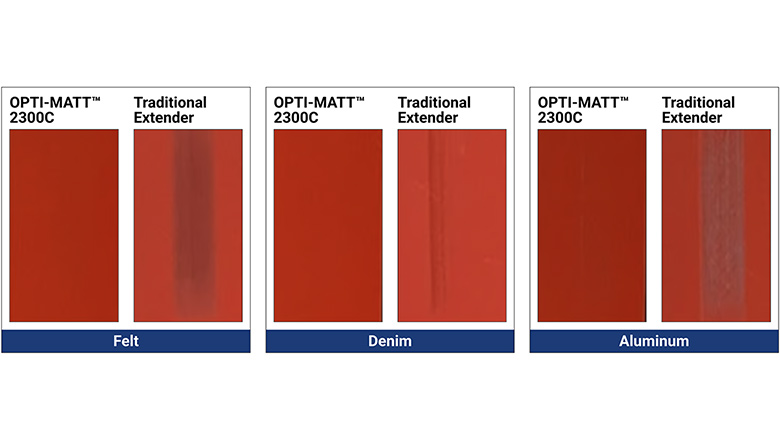

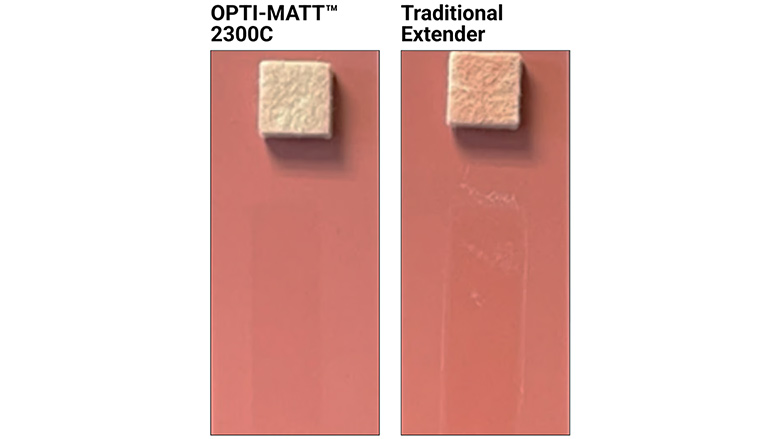

Evaluation of architectural coatings using OPTI-MATT™ 2300C Emulsion underscores the benefits in matte white and deep base paints. Comparisons of the mar resistance and color transfer of matte coatings formulated with OPTI-MATT™ 2300C compared to a similar coating formulated at equal PVC with a traditional inorganic extender are presented in Figures 1, 2 and 3.

Mar resistance was tested using a Veslic Tester model 402354 from SDL Atlas, fitted with felt, denim and aluminum test pads that were run across the film surface for 30 cycles. The paint formulated with OPTI-MATT™ 2300C has either no damage or significantly less damage compared to the paint formulated with the inorganic extender.

Color transfer resistance was tested using a Veslic Tester model 402354 from SDL Atlas, fitted with a wet felt pad that was run across the film surface for 50 cycles. The paint formulated with OPTI-MATT™ 2300C has no noticeable transfer of color to the white pad, while the paint formulated with the inorganic extender leads to transfer of the red iron oxide pigment to the felt.

EXP MT-8 Emulsion Polymer Pigment in Specialty Clear Coatings

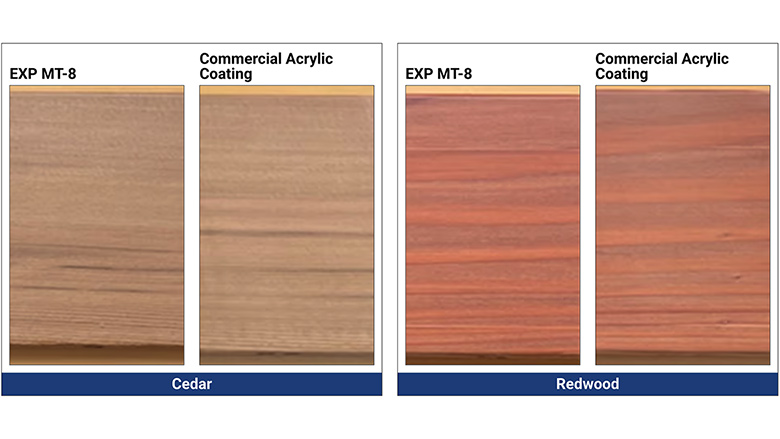

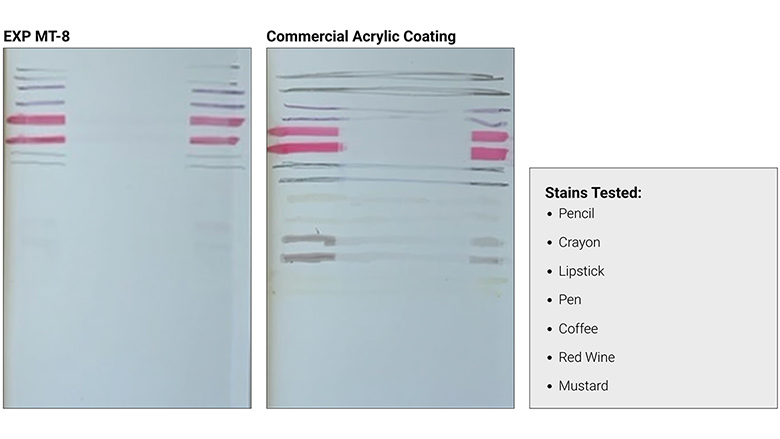

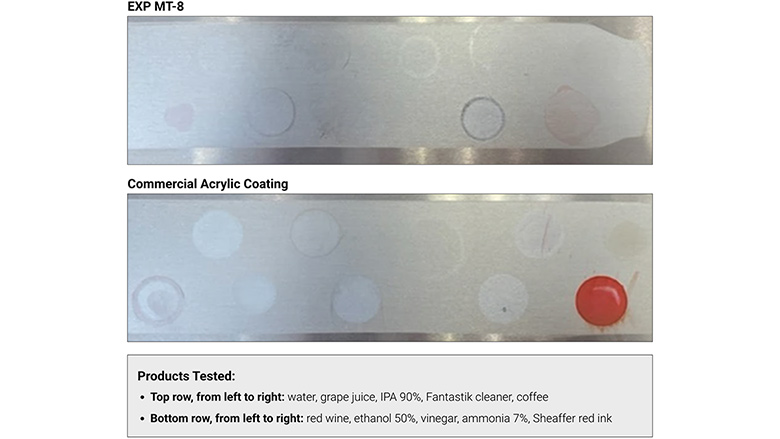

A clear flat wood coating was formulated with EXP MT-8 and RHOPLEX™ HG-98C Emulsion and compared to a commercial acrylic coating that contains inorganic matting agents. The formulation with EXP MT-8 matched the commercial product for gloss and sheen but had improved dry film clarity, stain resistance, and resistance to household chemicals.

Household stain resistance was evaluated by applying the clear coat to a white vinyl chart using a 7 mil Dow applicator. The film was dried for 7 days before the stains were applied and left in contact with the film for 2 hours prior to being washed following ASTM D2486.

Household chemical resistance was evaluated by applying the clear coat to untreated aluminum panels with a 7 mil applicator. The panels were dried for 7 days, and the chemicals were applied dropwise to the film, covered, and left in place for 16–18 hours before being blotted dry and evaluated for film damage.

Manufacturing Advantages

A key feature of the Durable Matte Technology is its capacity to eliminate the necessity for inorganic extender pigments and matting aids typically supplied in dry powder form. In turn, this eliminates the need for the high-speed dispersion process used to incorporate these materials. When OPTI-MATT™ 2300C is formulated into architectural coatings with a titanium dioxide slurry, there is no need for high-speed dispersion since all the pigments are supplied in liquid form. Likewise, when specialty clear coatings are formulated with EXP MT-8 as the flatting aid, the need to disperse a dry flatting aid is eliminated. This enhancement not only optimizes the manufacturing workflow but also can mitigate risks associated with handling dry and dusty powders.

Summary and Conclusions

Dow's Durable Matte Technology platform addresses the industry need for durable, scuff-resistant interior paints while maintaining aesthetic benefits of the more popular lower sheens. OPTI-MATT™ 2300C is Dow Coatings’ first offering from the platform supporting low-sheen durability, and the development of EXP MT-8 acrylic matting extender signifies further advancement, driving versatility across paint lines and extending scuff resistance solutions into specialty coatings. Dow drives forward with groundbreaking solutions — through our Durable Matte Technology platform and other areas —setting new standards for performance and sustainability in the coatings industry, helping to create a brighter and more sustainable future.

For more information, visit www.dow.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

-personnel-announcements-(1).webp?height=200&t=1681478349&width=200)