Comparative Evaluation of Electric and Manual Pencil Hardness Testing

- This article compares electric and manual pencil hardness testing methods used to evaluate coating hardness and film durability.

- Experimental results examine how testing speed, coating thickness and operator variability influence pencil hardness outcomes.

- Microscopic analysis highlights differences in scratch morphology and repeatability between manual and automated testing systems.

- The findings show that automated pencil hardness testing improves consistency reproducibility and measurement reliability in coatings evaluation.

A coating is a solid, continuous film formed by applying paint or similar material to substrates such as metal, fabric or plastic. It serves various functions including protection, insulation and decoration, thereby extending the service life of the underlying material. Among the performance indicators of coatings, hardness (also referred to as film hardness) is a critical measure of mechanical strength. It is a key quality parameter closely related to product durability and is a primary focus in product quality control.

At present, the main methods for testing coating hardness include the pendulum damping test, the pencil hardness test and the indentation hardness test. These correspond to the standards GB/T 1730–2007 Paints and varnishes—Pendulum damping test, GB/T 6739–2006 Paints and varnishes—Determination of film hardness by pencil test and GB/T 9275–2008 Paints and varnishes—Buchholz indentation test, respectively. Each method has its own advantages and limitations. Among them, the pencil hardness test is the most widely used in the coatings industry due to its simplicity, speed and low cost. In this method, pencils with known hardness grades are drawn across the coated surface and the hardest pencil that does not produce a scratch or defect 3 mm or longer indicates the coating’s hardness level.

Manual pencil hardness testers are widely used in practical applications. However, due to significant human influence during the testing process, the manual pencil hardness method suffers from drawbacks such as inconsistent speed and unstable applied force. With advances in science and technology, electric pencil hardness testers have attracted increasing attention.

This study compares the testing methods of electric and manual pencil hardness testers and investigates the factors affecting the test results. According to GB/T 6739–2006, the pencil must be pushed at a speed of 0.5–1 mm/s over a distance of at least 7 mm. In contrast, ISO 15184:2020 Paints and varnishes—Determination of film hardness by pencil test specifies that the pencil should be applied at a slow and constant speed over a sufficiently long period. To minimize the impact of speed variations on test outcomes, this study adopts the ISO 15184:2020 standard for testing.

Experimental Section

Materials and Instruments

Coated Test Panels (Supplied by GAC Honda Automobile Co., Ltd.)

- 60 μm (primer: 15 μm, intermediate coat: 10 μm, topcoat: 10 μm, clear coat: 25 μm)

- 80 μm (primer: 15 μm, intermediate coat: 20 μm, topcoat: 15 μm, clear coat: 30 μm)

- 100 μm (primer: 15 μm, intermediate coat: 25 μm, topcoat: 15 μm, clear coat: 45 μm)

Pencils

- Uni brand, Mitsubishi Pencil Co., Ltd.

Electric Pencil Hardness Tester

- BEVS 1309, manufacturer BEVS INDUSTRIAL (GUANG ZHOU) CO., LTD; testing speed: 0.5–8.5 mm/s; applied loads: 500 g, 750 g and 1,000 g

Manual Pencil Hardness Tester

- BEVS 1301, manufacturer BEVS INDUSTRIAL (GUANG ZHOU) CO., LTD; applied loads: 500 g, 750 g and 1,000 g

Inverted Metallographic Microscope

- DMi8A, Leica Microsystems

Testing Methods

Test Panel Preparation

Each test panel was prepared in accordance with GB/T 9271–2008. Prior to testing, the surface of each panel was wiped with alcohol using degreased cotton to ensure the coating was clean and free of contaminants.

Electric Pencil Hardness Testing Method

After placing the test panel on a stable horizontal surface, the electric pencil hardness tester was positioned on the panel. The horizontal alignment mechanism button was pressed to level the device and the counterweight was adjusted to 750 g. A pre-sharpened pencil was inserted, the alignment mechanism was reset and the operating speed and duration were set via the control panel. The test was then initiated.

Manual Pencil Hardness Testing Method

Testing was conducted in accordance with ISO 15184:2020 Paints and varnishes—Determination of film hardness by pencil test.

Optical Microscopy Analysis

The scratched area of each sample was placed on the microscope stage and brought into focus. Observations were made in bright-field mode using a 10× eyepiece and a 5× objective lens.

Results and Discussion

Effect of Coating Thickness

Table 1 presents the coating hardness values obtained using the two testing methods at different coating thicknesses. For the electric pencil hardness tester, the speed was set to 1.0 mm/s with a testing duration of 10 seconds. For the manual pencil hardness tester, the pencil was advanced slowly at a speed of 0.5–1.0 mm/s.

From Table 1, it can be seen that both the manual and electric pencil hardness testers yielded the same hardness values for coatings of different thicknesses. In general, the thinner the coating, the higher the measured hardness.

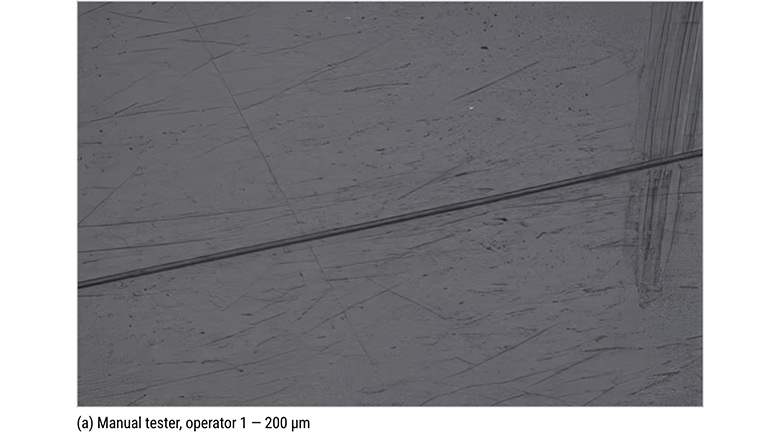

Figure 1 shows the optical microscopy results of pencil hardness (H) testing at different positions on a 60 μm thick coated panel using the manual pencil hardness tester. The hardness values obtained at different positions were F, HB and HB. Among them, the F and HB pencils left almost no visible marks on the coated surface, while the H pencil—having a higher hardness (H > F > HB)—left the most distinguishable mark, aligning closely with the final hardness rating. The manual and electric test results were consistent in this case.

As observed in Figure 1, even on the same test panel, scratches produced by pencils of the same hardness at different positions varied in form—some were just small points, while others were long or short scratches. This indicates that coating uniformity is also a key factor influencing pencil hardness test results. To ensure the reproducibility of results, it is essential that the coating thickness across the test samples remains consistent.

Effect of Testing Speed

Table 2 presents the coating hardness results obtained using the two testing methods at different testing speeds. For the electric pencil hardness tester, the speeds were set to 0.5, 1.0 and 2.0 mm/s, with a test duration of 10 seconds. For the manual pencil hardness tester, the pencil was advanced at low speed (0.5–1.0 mm/s) and high speed (2.0–3.0 mm/s), respectively.

From Table 2, it can be observed that the coating hardness measured using the electric pencil hardness tester remained consistent across different testing speeds. In contrast, the manual pencil hardness tester showed variation in results at different speeds. This discrepancy is primarily due to the manual operation method: higher speeds are achieved by applying a pushing force at the rear of the tester, while lower speeds rely on the operator holding and guiding it by hand. Since the testing speed is controlled solely by the operator’s perception, it may exceed the intended range. A faster and non-uniform speed increases the force exerted on the pencil lead, which in turn intensifies the damaging effect on the coating surface.

Compared to the manual method, the electric pencil hardness tester produces more reliable results because it maintains a constant and uniform testing speed, thereby minimizing the influence of speed on the measurement. This highlights that a uniform testing speed has a significant impact on the accuracy of coating hardness results.

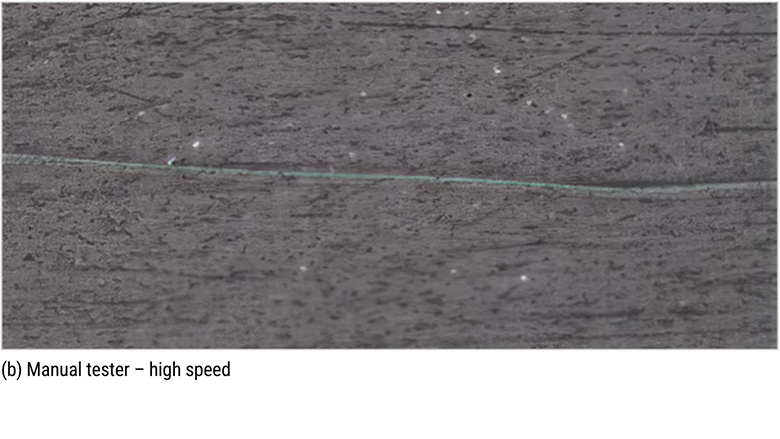

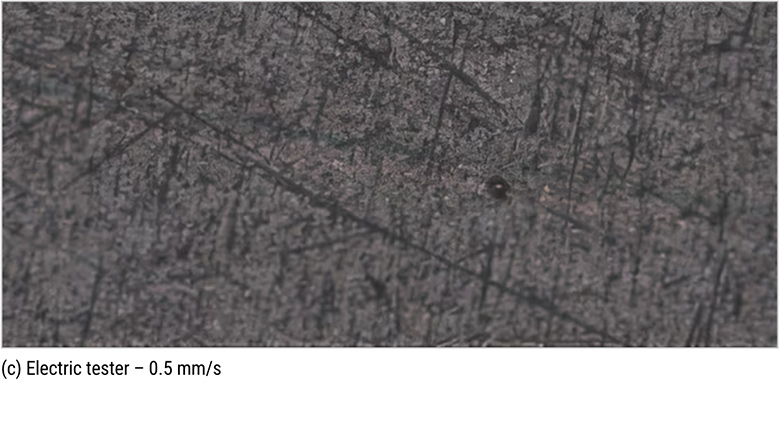

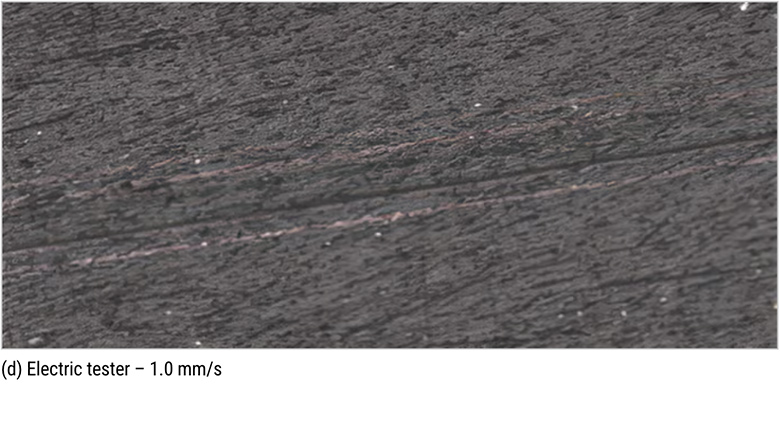

Figure 2 shows microscopic images of pencil hardness (F) results on a 100 μm thick coated panel at different testing speeds.

As seen in Figure 2, whether using the manual or electric pencil hardness tester, faster pushing speeds result in more pronounced marks on the coating surface. Under the microscope, this appears as darker traces, indicating greater damage to the coating.

Influence of Different Operators

Table 3 presents the coating hardness results obtained by different operators using the two testing methods. For the electric pencil hardness tester, the speed was set at 1.0 mm/s with a test duration of 10 seconds. For the manual pencil hardness tester, a fast pushing speed was used.

According to Table 3, experienced operators were able to achieve consistent results in their evaluations.

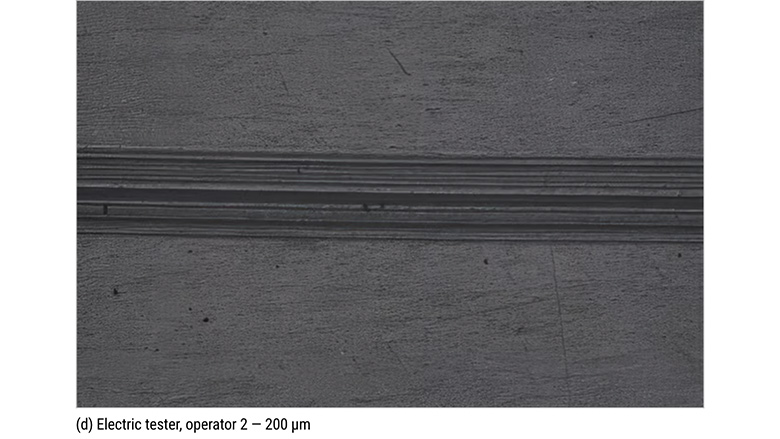

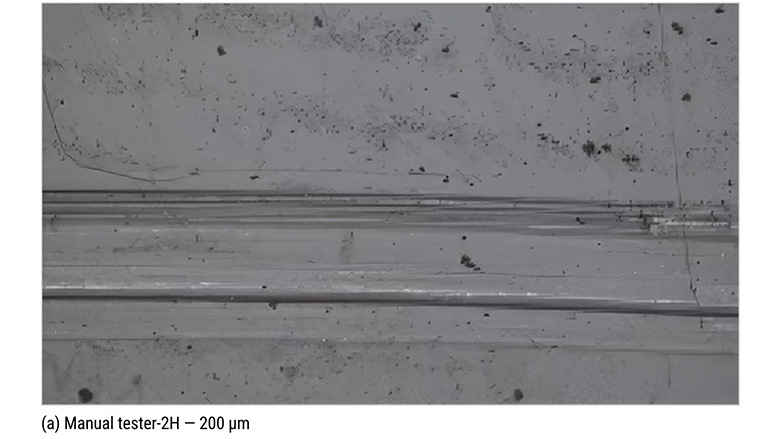

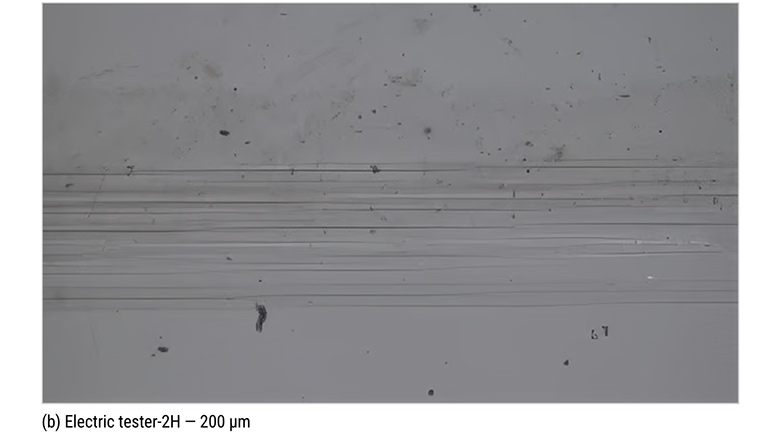

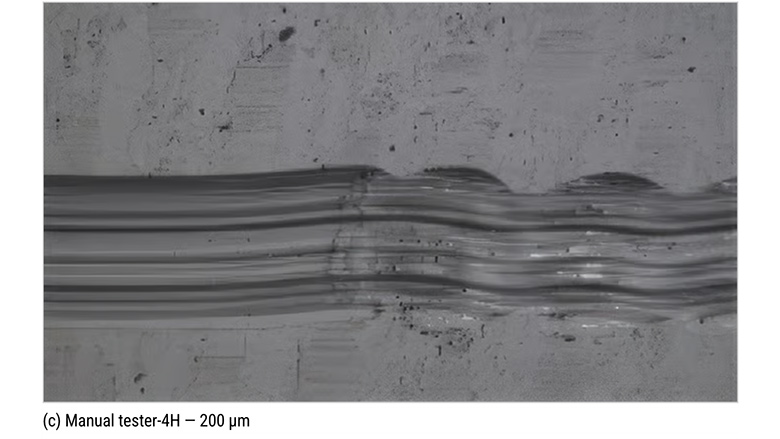

Figure 3 shows the microscopic results of pencil hardness (H) tests conducted by different operators on a 100 μm thick coated panel. Adjacent coating areas were selected for comparison to minimize the influence of coating variability.

As shown in Figure 3, when using the manual pencil hardness tester, the depth and appearance of the scratches varied among operators. Under the microscope, this is reflected by differences in scratch color, width and morphology. These inconsistencies are attributed to individual operator habits, such as differences in leveling the instrument, subjective interpretation and control of pushing speed, all of which can affect the results.

In contrast, the electric pencil hardness tester is equipped with an automated process control system. It requires no manual leveling and ensures a uniform, stable testing speed. This minimizes operator influence and leads to more consistent scratch depths, which under the microscope are observed as more uniform coloration.

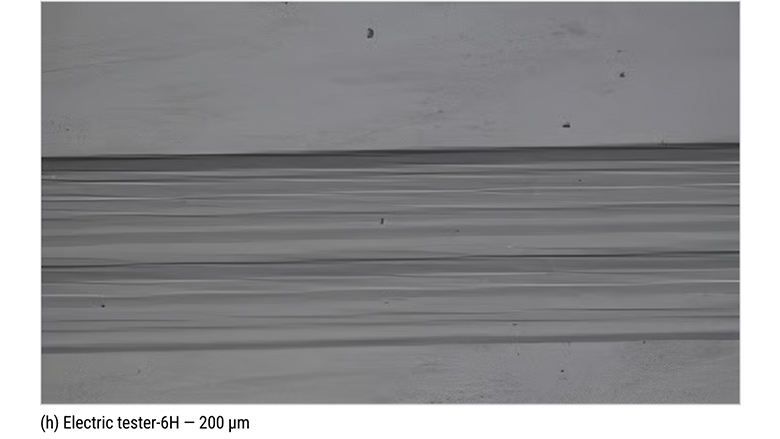

Microscopic Analysis of Results

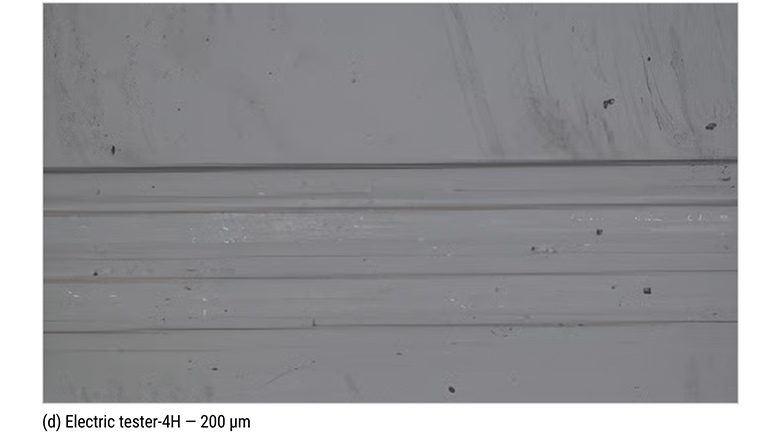

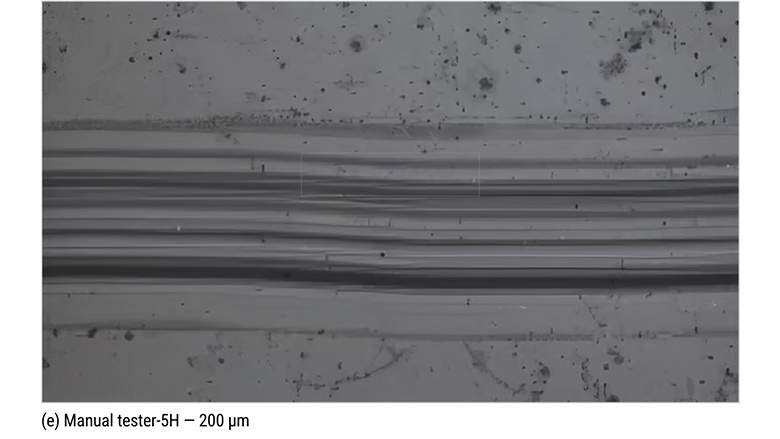

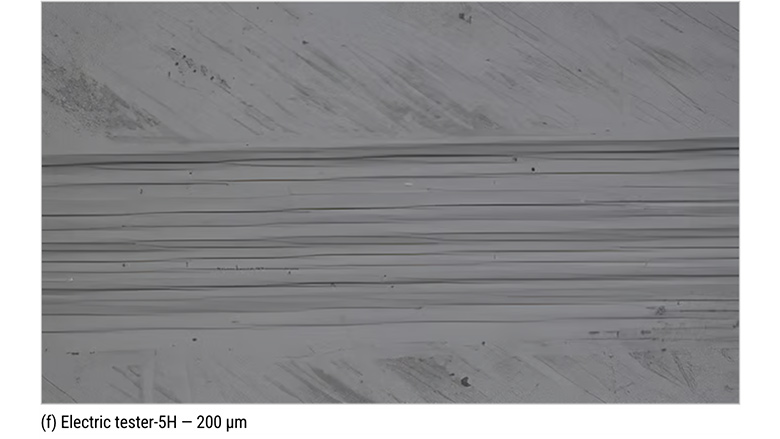

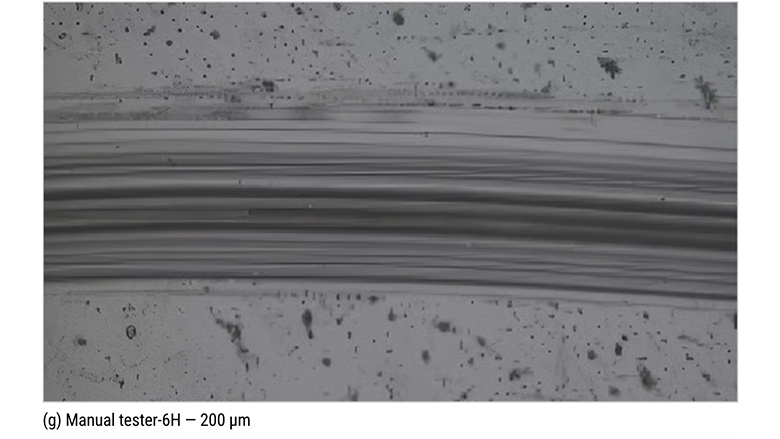

To better investigate the influencing factors of pencil hardness testers, a coating with a thickness of 100 μm was selected as the research subject. Pencils with hardness grades of 2H, 4H, 5H and 6H were used to create scratches on the coating surface at a speed of approximately 1.0 mm/s using both manual and electric pencil hardness testers. The resulting scratches were then magnified 50 times using an inverted metallographic microscope for analysis. The results are shown in Figure 4.

As shown in Figure 4, with increasing pencil hardness, the scratch marks appear progressively darker in color. For the same pencil hardness, scratches made using the manual pencil hardness tester are noticeably darker than those made with the electric tester. Moreover, the scratch lines produced manually are often discontinuous, uneven and non-linear, with occasional gaps. This is particularly evident with the 4H pencil. In contrast, scratches made with the electric tester are smooth and consistent.

Although both testing methods applied a load of 750 g, the manual tester is prone to unintentional excess pressure during operation, resulting in deeper scratches compared to the electric tester. Consequently, under the same coating thickness, defects tend to appear earlier when tested manually. Additionally, due to the inability of the manual tester to maintain a uniform speed, human-induced variability significantly affects the consistency and quality of the scratch marks.

Optical microscopy analysis further confirmed the influencing factors affecting the results of pencil hardness testing. The electric pencil hardness tester consistently yielded higher hardness values than the manual tester, with better reproducibility. Additionally, the electric tester demonstrated higher testing efficiency.

Based on the experimental results, factors such as test panel preparation, instrument performance, coating properties, test speed, horizontal alignment and applied load all have an impact on the accuracy of coating hardness measurements. These factors have a more pronounced effect on the manual pencil hardness test. In contrast, due to its automation, the electric pencil hardness tester significantly reduces the influence of these variables, thereby improving the consistency and reliability of the test results.

Comparative Analysis of Electric and Manual Pencil Hardness Testers

Five types of coated test panels were selected and tested by experienced operators using both the electric and manual pencil hardness methods at a speed of 1.0 mm/s. The repeatability of the results (GRR) was calculated. The test results are shown in Table 4.

Note: GRR refers to Gage Repeatability and Reproducibility. The criteria for GRR evaluation are as follows:

- GRR ≤ 5%: indicates excellent repeatability of the measurement system

- GRR ≤ 10%: indicates the measurement system is acceptable

- 10% < GRR < 20%: may or may not be acceptable, depending on factors such as the importance of the measurement system or cost of improvement

- GRR ≥ 20%: indicates the measurement system is unacceptable and requires improvement

According to the analysis of Table 4, the electric pencil hardness tester demonstrates better repeatability and reproducibility than the manual pencil hardness tester. In addition, the electric tester offers faster measurement speed and higher efficiency.

To further verify the practicality and reliability of the electric pencil hardness tester, a third-party testing agency, Guangdong Testing Institute of Product Quality Supervision, was commissioned to test Sample Panel 1, Panel 2 and Panel 3 using both the electric and manual pencil hardness testers. Each panel was tested under different applied loads: 500 g, 750 g and 1,000 g. The results are shown in Table 5.

Note: The testing methods refer to GB/T 6739—2006.

As shown in Table 5, the measurement results from both methods are consistent, demonstrating the accuracy of the electric pencil hardness tester and confirming the instrument’s practicality.

Conclusion

The measurement of coating hardness is influenced by several factors, including the performance of the testing apparatus, coating thickness, testing speed, level positioning and applied load. Due to the variability introduced by manual operation, the results obtained using a manual pencil hardness tester often lack consistency and reproducibility. Accurate testing with a manual tester heavily depends on the operator’s technical proficiency.

In contrast, the electric pencil hardness tester offers better control over influencing factors, reduces errors and improves the accuracy and repeatability of the results.

This study contributes to ongoing discussions around testing methods and quality control practices used in industrial coatings.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!