Front Line Corrosion Defense

Edge Protection

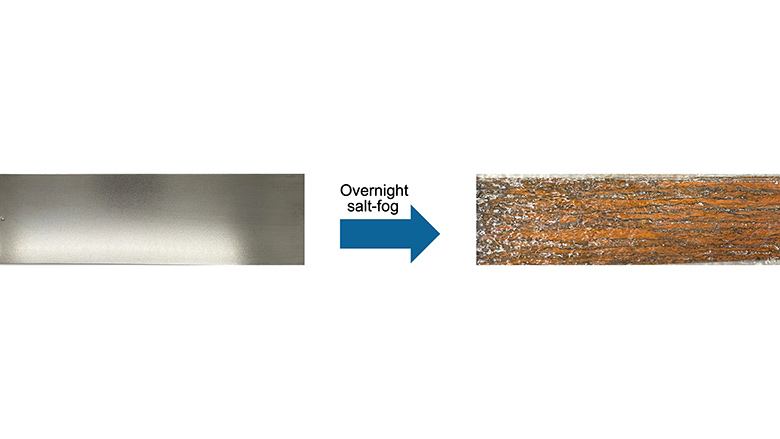

Corrosion remains a persistent challenge across numerous industries worldwide, leading to significant economic losses, safety concerns and infrastructure vulnerability. Metals — particularly steel substrates — readily react with water, salts and caustic chemicals, leading to degradation (Figure 1). Industries such as protective, marine, heavy-duty equipment, architecture, aerospace, automotive and defense are all affected, with corrosion-related costs reaching hundreds of billions of dollars annually. These costs include prevention and control programs, maintenance, investments in corrosion-resistant technologies and innovative coatings. The National Association of Corrosion Engineers (NACE) estimates the global cost of corrosion to be in the trillions of dollars.¹ To address this, the industry has adopted various approaches, from manufacturing innovations to advanced coating solutions. Optimal coatings delay the corrosion process, extending asset lifespans and reducing maintenance and recoating costs.

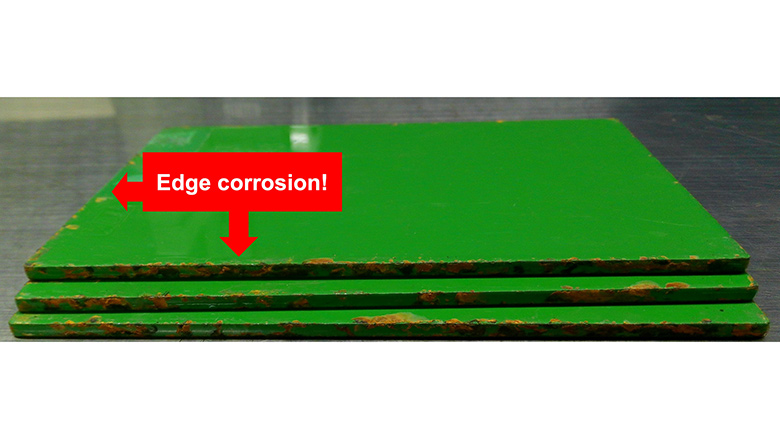

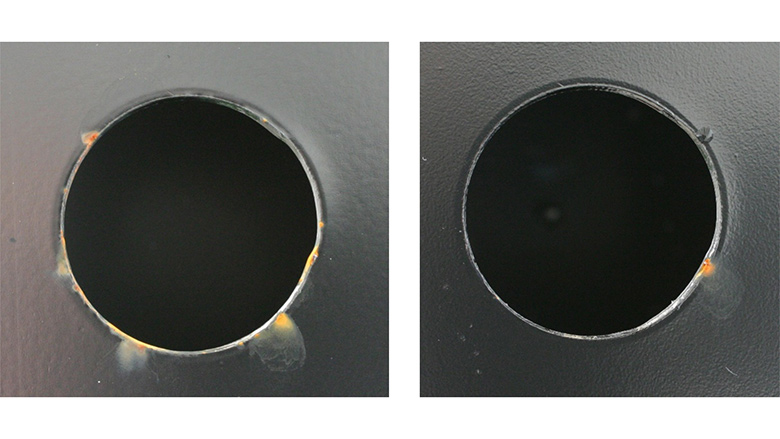

Corrosion often begins at vulnerable areas such as sharp edges, crevices, fasteners, welds, corners and high-profile surfaces. As shown in the exposed panels below, the corrosion process initiates at sharp edges first and then spreads across the surface.

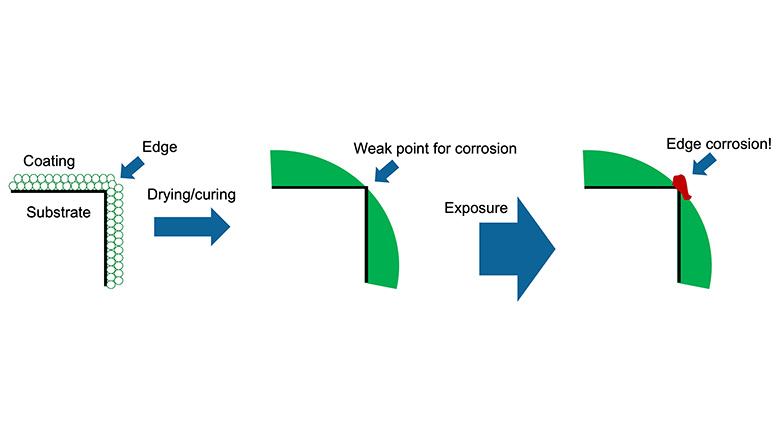

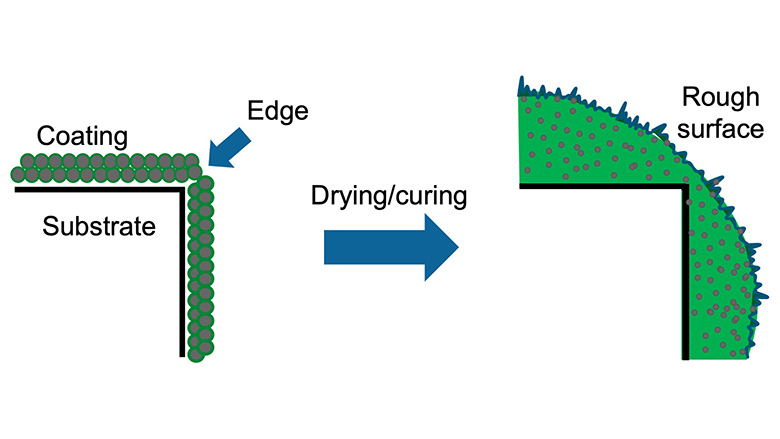

Sharp edges are historically difficult to protect because coatings tend to flow away from them during application and curing. Contributing factors include non-optimal surface energy, electrostatics, rheological changes during curing and solvent loss. The resulting thin coating layer at edges becomes a weak point where corrosion initiation and propagation occur (Figure 3).

This article focuses on edge corrosion — the first site of deterioration — and explores strategies for achieving robust edge coverage and protection in both liquid and powder coating technologies. It also examines the interplay between edge coverage and surface roughness, highlighting opportunities for innovation. Despite differences between powder and liquid coatings, many edge coverage solutions are applicable across both technologies.

How to Manage Edge Corrosion

The coatings industry has adopted several methods to delay edge corrosion. While some are time-consuming and costly, they ultimately improve edge protection. Below are key approaches, including recent advancements:

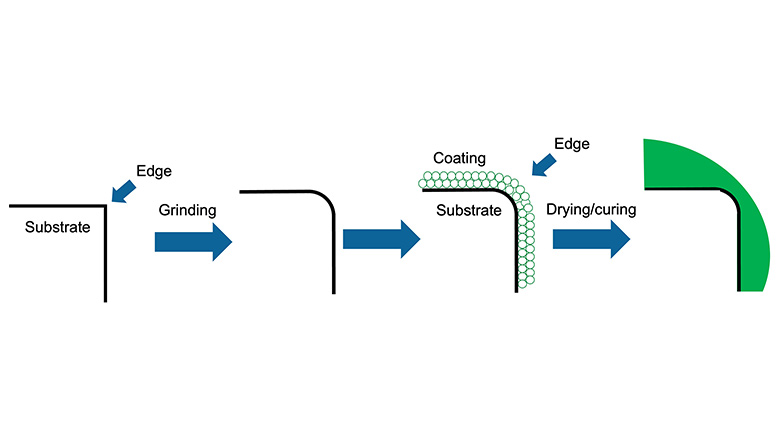

Grinding and Abrasive Blast Cleaning

Grinding and grit-blasting the steel substrate are commonly used to round sharp edges, as detailed in a KTA-Tator article.² While effective and commercially adopted, these methods are labor-intensive and expensive. Additionally, not all areas are accessible for grinding or blasting.

High Pigment-to-Binder Ratio

Increasing pigment concentration restricts paint flow during curing, improving edge protection but compromising appearance. It also introduces challenges in application and film formation but results in poor film appearance.

Pigment Stratification

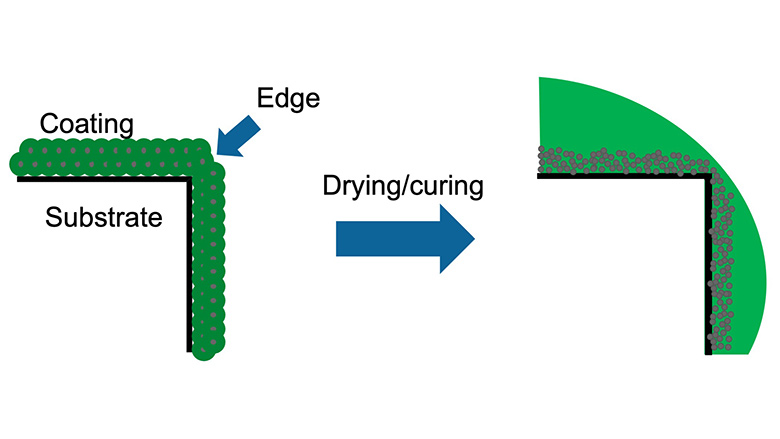

Pigment stratification overcomes appearance issues associated with high pigment loads. Pigments stratify to the substrate while binder technologies maintain appearance.³ Hydrogel4 additives are used to achieve this stratification.

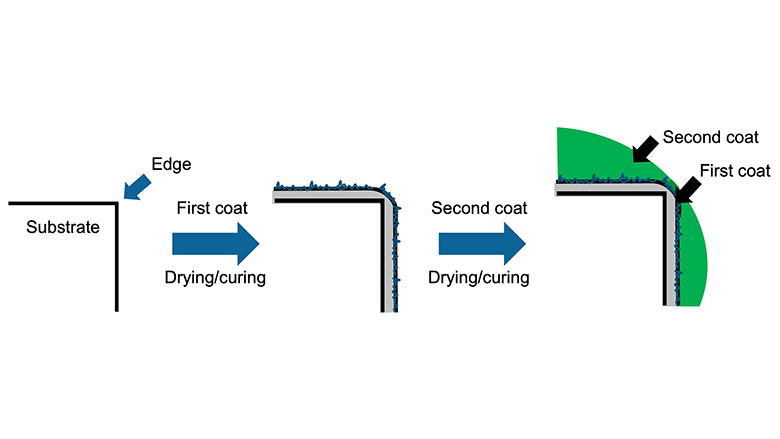

Multi-Layer Approach

Stripe coating, as described in SSPC Paint Guide No. 11 and the KTA article by James D. Machen, involves applying a targeted coat on edges before the full system. Two-coat systems are also common but require separate oven bakes, adding time and cost. Two-layer systems can be further covalently5/non-covalently reacted to further improve edge coverage.

Rheological Modification6

Edge corrosion often results from coatings flowing away from edges. The introduction of rheology control additives significantly improves edge coverage and corrosion resistance. This concept is demonstrated in both liquid and powder technologies.

PPG’s POWERCRON® 10X™ electrocoat uses proprietary microgel resin technology to optimize rheology.7 Microgels are high-molecular weight emulsions that restrict flow during curing, enabling robust film build with minimal roughness. After 672 hours in salt spray testing, Powercron shows less than 1% edge corrosion compared to ~50% with conventional coatings (Figure 8).

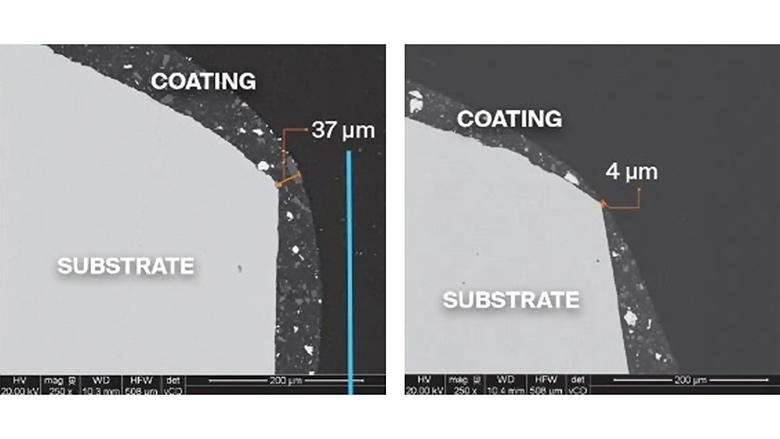

PPG’s ENVIROCRON® Extreme Protection Edge powder technology also uses proprietary rheology modifiers to restrict melt flow at edges during curing. Compared to standard single-coat systems, Envirocron powder technology achieves significantly higher edge coverage (37 µm vs 4 µm). As a result, the Envirocron powder edge formulation significantly outperforms conventional formulas on a single coat on laser cut edges.

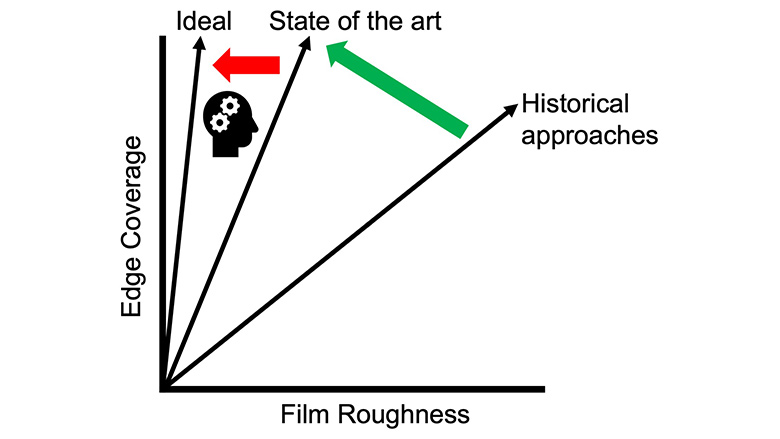

Edge Coverage vs Appearance

While the coatings industry has made strides in edge protection, it often comes at the expense of appearance. Rheology control, multi-coat and stratification approaches aim to balance both. Typically, thicker films improve edge coverage but reduce visual quality (Graph 1). Achieving optimal corrosion resistance with a high-quality finish remains a challenge, and future innovations are expected.

Conclusions

Delaying edge corrosion is critical in maintaining architectural, commercial and industrial assets. A range of solutions such as grinding, blasting, multi-coat and single-coat systems are available across liquid, electrocoat and powder technologies. Envirocron powder technology offers a compelling combination of edge protection and appearance in a single coat.

Ultimately, prevention is more cost-effective than repair. Choosing the right coating, conducting regular inspections and addressing field failures promptly are key to extending asset lifespans. While current technologies offer improved edge protection, there remains significant potential for future advancements — particularly in achieving automotive-grade finishes with superior edge coverage.

Acknowledgments

Marisol Rodriguez, Susan Donaldson, Antonio Belletti, Dave Walters, Genna Niemiec, Brian Woodworth and Casey Sample.

References

¹ Pearman, B.; Zhang, X.; Campbell, D.; Scarborough, V.; Dickey, S. Sustainable, Smart Corrosion Protection. Paint & Coatings Industry Magazine, May 9, 2025. https://www.pcimag.com/articles/114123-sustainable-smart-corrosion-protection.

² Preparation of Edges for Coating Performance. KTA-Tator. https://kta.com/edge-preparation-for-coating-performance.

³ The Flawless Edges and Throwpower of Electrocoating. Chemetall. 10381-E-Coat-Line-Card-Update-R2.pdf.

⁴ Bashir, S.; Hina, M.; Iqbal, J.; Rajpar, A. H.; Mujtaba, M. A.; Alghamdi, N. A.; Wageh, S.; Ramesh, K.; Ramesh, S. Fundamental Concepts of Hydrogels: Synthesis, Properties, and Their Applications. Polymers 2020, 12 (11), 2702.

⁵ Shevrin, J. D.; Bergman, S. D. Crosslinking Waterborne Coatings with Bipodal Silanes for Improved Corrosion Protection Performance. American Coatings Association. https://www.paint.org/coatings-tech-journal/crosslinking-waterborne-coatings-with-bipodal-silanes-for-improved-corrosion-protection-performance.

⁶ Shaffer, K. Advancement in Edge Corrosion Protection. 2019 CoatingsTech Conference, April 8, 2019.

⁷ Sample, C. High Edge Coverage Electrocoat Development for Enhanced Corrosion Protection. TRI-Service Corrosion Conference, 2007.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!