Zero-Carbon Calcium Carbonate

For paint and coatings

Paint and coatings need minerals. And in today’s world, the minerals that paint and coatings need must show that they can have an ever-reducing carbon footprint and are sourced from more sustainable resources. Having a low carbon footprint for minerals not only serves to create paint and coatings for a more sustainable world, but it also allows for greater flexibility for formulators to use alternative materials that help reduce the overall carbon footprint. Formulators must balance performance, cost and sustainability to select the right calcium carbonate for the job.

CarbonFree introduced a zero-carbon footprint calcium carbonate for the paint and coatings industry — endurocal® calcium carbonate (ECC). This calcium carbonate helps formulators meet sustainability targets without compromising cost or performance. Adding the mineral to a formulation portfolio gives formulators a pathway to reduce the footprint of paint and coatings products.

Conventional Calcium Carbonates

Smoothness. Brightness. Durability. Whitening. Opacity. Cost Efficiency. The benefits of calcium carbonate make it an essential mineral for paint and coatings. It serves as an extender, improves opacity and helps optimize formulation cost.

There are two primary methods of producing calcium carbonate for coatings:

- Ground calcium carbonate (GCC)

- Precipitated calcium carbonate (PCC)

Both start with mining a natural calcium carbonate deposit. GCC requires surveying, exposing, mining, transporting, grinding, sizing, purifying and drying the mineral. PCC requires additional processing energy: the GCC is calcined into lime, releasing CO₂, then hydrated with water to calcium hydroxide and finally carbonated back into calcium carbonate. Both processes demand significant energy and contribute to a higher carbon footprint while consuming finite natural mineral resources.

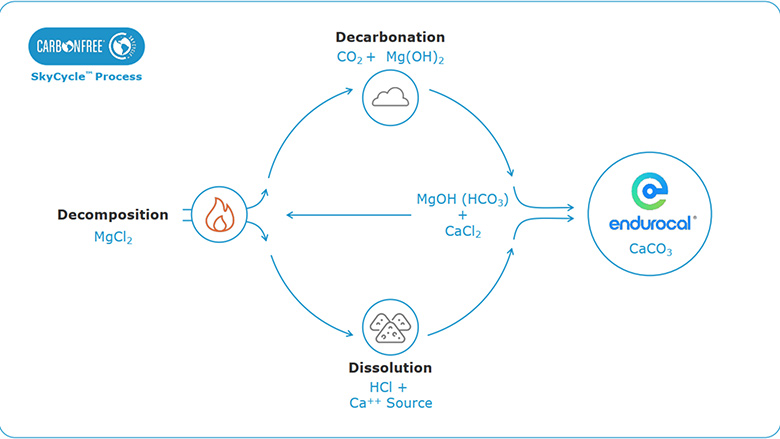

The Zero-Carbon Calcium Carbonate Process

To help formulators reduce their environmental impact without compromising on those characteristics of calcium carbonate key to performance, a new manufacturing process was developed. The product is a calcium carbonate made by a whole new method that has a negative-carbon footprint.1 It is made using CarbonFree’s proprietary SkyCycle™ technology. This process uses extractable calcium from post-industrial sources and captured CO₂ from industrial emissions. The process takes materials that have a direct negative impact on the environment and creates a product that can offset other calcium carbonates that are also having a direct negative impact on the environment. Magnesium and chloride cycles shuttle the CO2 and calcium along to combine and make the calcium carbonate from magnesium bicarbonate and calcium chloride. A low-energy decomposition that pulls waste energy from onsite sources, thus contributing to lowering the carbon footprint of the process.

The resulting high-purity calcium carbonate is produced through a collaboration between CarbonFree and U.S. Steel. The process utilizes post-industrial slag as the calcium source and CO₂ from the blast furnace as the carbon source. Both streams were previously uneconomical to reuse, making this a circular pathway that offsets the footprint of traditional calcium carbonates.

By substituting conventional calcium carbonate with the zero-carbon option, manufacturers gain a multiplier effect on carbon reduction. The process uses waste materials and offsets the footprint of a carbon-positive material already used in coatings. Because the mineral can be produced with a negative carbon footprint, it contributes to reducing Scope 3 emissions.1

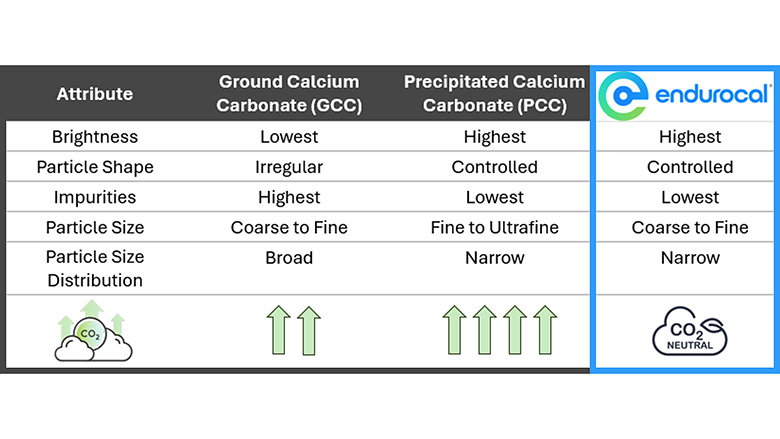

Comparison to Conventional Calcium Carbonates

Differences and similarities between GCC, PCC and the zero-carbon calcium carbonate are shown in Figure 2. CarbonFree’s product looks more like the PCC in almost all attributes, and it still has some similarities to the GCC. The key distinction is that the mineral has a zero-carbon footprint.

Typical Properties of Zero-Carbon Calcium Carbonate

The properties are shown in Table 1. The zero-carbon calcium carbonate demonstrates a mean particle size of about 7 µm, although other sizes can be produced. The high oil absorption value is typically associated with much smaller particle sizes. This, coupled with a similar loose and tapped density, implies that the mineral has a structured, discrete particle size. The high oil absorption value is typically associated with much smaller particle sizes. Combined with similar loose and tapped bulk densities, this indicates a structured particle. Given the particle size data, SEM image and high OA, it indicates that the mineral is highly agglomerated and highly structured, but can delaminate with a reasonable amount of energy. Deagglomeration yields smaller particle sizes and higher brightness.

The Future of Sustainable Coatings with Zero-Carbon Footprint Calcium Carbonate

By substituting one-for-one for existing high-energy calcium carbonates, the carbon footprint of paint and coatings is reduced, and previously unusable raw materials are repurposed, utilized to offset harmful greenhouse gases, avoid mining finite natural resources and avoid further environmental harm.

Finding innovative ways to make paint and coatings more sustainable can and should start at the mineral level. Practically, it allows for greater flexibility for formulators to use alternative materials that reduce their carbon footprint, but on a macro-level, it serves to enable a more sustainable future for homes, buildings and infrastructures.

Footnotes

1 The carbon negative estimate and the positive PCC estimate compare the 100-Year Global Warming Potential (GWP100) of the SkyCycle process to the traditional PCC process in metric tons CO2e to metric tons of calcium carbonate produced with openLCA. The values were calculated via Trinity Consultants, Inc. LCA based on a hypothetical facility not based on actual operating data.

Learn more about sustainable raw materials within the coatings sector.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!