Selecting Raw Materials for High-Performance Latex Paint Formulations

The selection of raw materials for the formulation of latex paint is a kind of maze in which the formulator not only has to find mutually compatible raw materials but also balance the quality of the resulting formulation with its price. To calculate the cost contribution of each raw material in the recipe, you need to know which materials will be included in testing, what their dosage and percentage in the formulation will be, and how they influence the quality parameters established at the beginning of the project compared to competing raw materials. You also cannot forget issues related to the raw material’s impact on VOC, product labeling (GHS, NFPA 704, HMIS) and its environmental impact such as carbon footprint, sustainability, transport costs, and legal regulations. It is a real mess that needs to be sorted out and systematized, especially for beginner formulators who do not have this type of knowledge handed to them on a plate.

To start selecting raw materials, we must prepare assumptions about what type of paint should be formulated and what liquid parameters and coating properties it must have. Will it be a flat paint (matt), a higher-gloss product, or something in between such as velvet-like, satin-like, or eggshell? What durability parameters must the coating meet and what areas of application should it be adapted to, such as interior or exterior use? Should it resist water, disinfectants, stains, or other exposures? A wide range of properties must be defined as acceptance criteria for the formulation, for example specific targets like a spattering rating of at least 8 when roller-applied, scrub resistance of at least 1,200 cycles to failure, or a whiteness index of at least 85.

The next step is to build the formulation and select raw materials for testing that will meet these criteria. This is a complex process that requires experience and often the support of a professional consultant in raw material selection. The next step is to calculate raw material costs in relation to performance in a formulation that must deliver specific parameters. But how should you interpret raw material parameters, evaluate case study results, and choose samples for testing at the R&D stage? This article is a starter guide for novices as well as a reminder for advanced formulators. It has been created by a laboratory dedicated to building knowledge about the effectiveness of raw materials in latex paint formulations as a compact knowledge pill.

Regulatory Review Before Testing

If we have already defined what type of latex paint we want to formulate in terms of liquid and coating parameters, the first step in selecting raw materials should be to review their Safety Data Sheets and any additional documents describing classification under various legal regulations. The growing market awareness of sustainability means that more raw materials now contain some bio-based components or are even fully bio-based. This information is also useful during material selection and should be reviewed carefully.

When examining SDS documents, pay particular attention to the labeling of the raw material and the hazards it presents, both in its supplied form and when used at specific concentrations in a formulation. In the case of latex paint, GHS pictograms are undesirable in many markets. These concerns usually apply to biocides but can also extend to polymer dispersions and additives such as coalescents. It is very important to evaluate the presence of SVHC ingredients, as well as any hazards indicated by the manufacturer. For example, a raw material marked with the GHS 08 pictogram and phrase H350 — may cause cancer if inhaled (Figure 1), in contact with skin or if swallowed — requires careful consideration.

A conscious choice to test a raw material with unfavorable labeling does not necessarily influence the labeling of the final paint because everything depends on concentration and its share in the formulation. However, a deliberate approach to accepting such a material for testing is necessary. Using it in the laboratory will require proper personal protective equipment, and it may affect safety considerations in production, storage, and end use, including the need to recommend specific safety standards.

If the raw material comes from outside your country, it is necessary to check whether it is registered under REACH or an equivalent registration system in your region. Otherwise, there may be problems with purchasing or importing it. It is equally important to become familiar with local regulations regarding waste disposal, fire hazards if applicable, and any other local rules governing use of the material. In applications where contact with food may occur, you must verify whether the manufacturer provides a document such as Food Contact Information, that specifies whether the raw material can be used to formulate coatings for food contact. These documents often define the allowable concentration, expressed for example in mg/m2 of coating, as well as relevant compliance criteria such as FDA 21 CFR 175.105 or FDA 21 CFR 175.300.

Only after reviewing hazardous ingredients, labeling requirements, legal regulations, VOC content, green-labeling criteria such as the EU Ecolabel, and other regulatory considerations can you proceed to laboratory testing to evaluate the raw material’s functionality in formulations. It is not advisable to replace this step with a simple analysis of purchase price per kilogram because, especially in the case of additives, a higher price per kilogram does not necessarily mean a higher cost in the final paint. An additive may be so effective that its dosage is very low, resulting in minimal impact on final formulation cost. However, purchasing departments often intervene before testing and compare prices per kilogram without understanding performance.

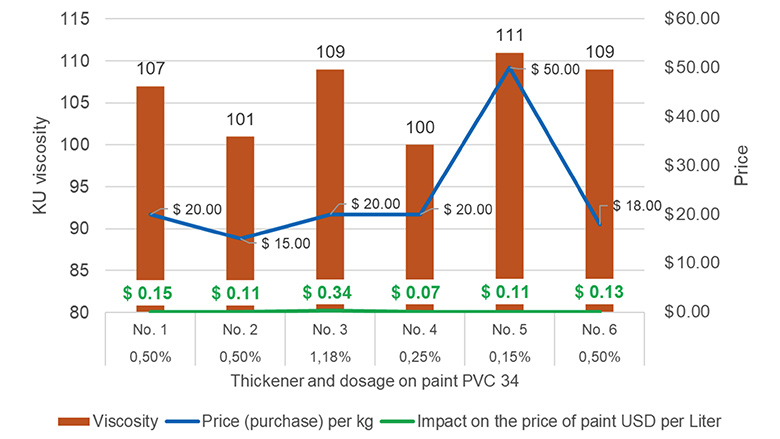

Figure 2 shows an example comparing the effectiveness of clay thickeners (phyllosilicates) in terms of building viscosity in the mid-shear range (KU viscosity) to the desired range of 90-110 KU. The chart shows KU viscosity obtained in a PVC 34 latex paint formulation for various thickener dosage levels, expressed as active substance on total formulation, and compares the purchase price per kilogram with the resulting impact on the cost per liter of paint.

Based on the example in Figure 2, one of the thickeners (#5) is very expensive at USD 50/kg. Its effectiveness at a dose of 0.15% active ingredients allowed the formulation to reach the desired viscosity, resulting in an impact on paint cost of USD 0.11/L. In contrast, thickener #2 costs USD 15/kg and also achieved the desired viscosity range at a dosage of 0.50%, giving the same cost impact per liter. Thickener #3 costs USD 20/kg, but it required a dosage of 1.18% active ingredients to reach the target viscosity. This resulted in a cost impact of USD 0.34/L, which is three times higher than thickener #5 even though thickener #5 has the highest price per kilogram. These examples show that the purchase price alone should not determine raw material selection. Performance in the formulation should always come first, followed by cost analysis.

Raw Materials Technical Data

When assessing the functionality and performance of raw materials in formulations, you should start by reviewing their Technical Data Sheets. Depending on the type of raw material, the data in a TDS may be more or less extensive, but it always provides the basic information needed for understanding the ingredient you plan to use. Below are some examples that illustrate how to correctly interpret the information contained in these documents.

Polymer Dispersions

The characteristics of polymer dispersions are usually similar across manufacturers and often include data such as:

- Type of polymer dispersion (acrylic, styrene-acrylic, vinyl-acrylic)

- Solid content, for example 48% by weight

- Surfactant, stabilization, or emulsifying system such as anionic, non-ionic, anionic/non-ionic, protective colloid systems commonly used for vinyl acetate copolymers, and APEO-free surfactants

- Minimum film-forming temperature such as MFFT 73 °F / 23 °C

- Glass transition temperature such as Tg 79 °F / 26 °C

- Viscosity, for example 800 to 1,800 mPa·s, or greater than 300 mPa·s, typically measured using a Brookfield viscometer

- Density, usually 8.5 to 8.8 lbs/US gal or 1.02 to 1.06 g/cm3

- Average particle size, for example 50 nm for fine particles, 80 to 150 nm for typical acrylic or styrene-acrylic dispersions, and 0.2 to 2.0 µm for vinyl acetate copolymers

- pH values such as 4.5 to 8.0 for vinyl acetate copolymers or 6.5 to 8.5 for styrene-acrylic or acrylic copolymers

Not all of these parameters are always included, but they represent typical characteristics that help the formulator understand the basic identity and behavior of the binder. Additional information sometimes found in TDS documents includes:

Mechanical Stability

Mechanical stability refers to the resistance of a polymer dispersion to destabilization under high shear forces. This is usually expressed as excellent resistance or no resistance. The parameter is typically tested using internal procedures with equipment that generates high shear, such as an Ultra-Turrax or Silverson mixer. These conditions can destroy surfactants and cause coagulation. Stability is assessed visually or using a sieve. This information indicates whether the polymer dispersion is suitable for a one-pot paint production process where grinding and let-down occur in a dissolver. If a dispersion has poor mechanical stability, it should be added during a let-down step in a separate equalizer rather than processed in a dissolver.

Freeze-Thaw Stability

Freeze-thaw stability indicates whether the polymer dispersion exhibits coagulation or other defects after freeze-thaw cycling. The result is often expressed briefly, such as “passed 5 cycles,” although this is not very informative due to lack of details about cycle duration or temperatures. The assumed standard is often ASTM D2243 at –18 °C, but this is not always stated. It should be understood that this parameter reflects only a visual assessment of the sample after freeze-thaw cycles and does not guarantee that the dispersion retains all its original properties.

Elongation at Break

This parameter describes how much the polymer film stretches before breaking. It is expressed as a percentage, for example 600%, which means the film can stretch to six times its original length without failure.

In addition to these parameters, a TDS for a polymer dispersion usually includes recommended applications such as wall paints, wood coatings, primers, or direct-to-metal coatings. Storage information, such as shelf life and recommended storage temperature, is also provided. In some cases, performance data is included with recommended coalescents, dispersants, defoamers, or other additives, especially when the dispersion manufacturer also supplies these additives.

Titanium dioxide pigments

Titanium dioxide is the most expensive raw material in latex paint formulations. Its use is usually optimized by selecting the minimum amount necessary to provide hiding power and adjusting the formulation with functional fillers or extending pigments. Because titanium dioxide contributes significantly to formulation cost, there is no room for accidental or ineffective use, and the TDS is a helpful tool for making informed choices.

A titanium dioxide TDS typically includes the type of pigment, such as rutile or anatase, with rutile varieties being most common. It also includes whether the pigment is produced by the chloride process or the sulphate process. Additional parameters may include median particle size, oil absorption, specific resistance, bulk density, titanium dioxide content, and classification according to ASTM D476 and sometimes ISO 591-1.

The ASTM D476 classification is especially useful because it defines pigment types and their recommended end-use applications. Table 1 summarizes these classifications with associated applications.

Although not all titanium dioxide TDS documents list the ASTM D476 classification, most do. The classification helps the formulator select the appropriate pigment grade for a specific coating.

For example, when developing a low-cost formulation with high PVC, the best choice is usually a highly surface-treated type III pigment. A titanium dioxide content of at least 80% indicates a high level of surface treatment. This type improves dispersion and supports binder efficiency in PVC values above 80%, providing better particle spacing in densely filled systems.

For high-gloss enamel formulations with low PVC, type II is recommended, with type VII as a second choice. For high-durability exterior coatings, type V is preferred. Because each type is associated with specific performance characteristics, the ASTM D476 classification is extremely helpful for selecting the correct pigment for testing.

For titanium dioxide manufacturers, including this classification in the TDS is a valuable technical marketing tool. It allows the manufacturer to support customers with clear recommendations for a wide range of pigment grades based on real application testing.

PERFORMANCE IN FORMULATIONS

To use raw materials effectively in latex paint formulations, a series of application tests must be carried out to determine whether each ingredient meets the assumptions established at the beginning of the project. Selecting samples for testing from different suppliers is not easy, and additional technical documents such as case studies, guidelines, or application data sheets can support the decision-making process. These materials go far beyond what appears in TDS documents and contain the results of application tests that show how to use individual ingredients effectively and how to work efficiently with each raw material.

A TDS does not provide the key information needed for recommended use in specific formulations. Therefore, the next step in selecting raw materials is an analysis of case studies, application guidelines, and additional technical documentation that show how binders, additives, or fillers behave in real formulations. Some examples of key performance data for polymer dispersions include:

- Performance across the full PVC range and resulting scrub resistance

- Binding capability in formulations containing fillers with high oil absorption such as kaolin

- Gloss levels obtained in low PVC formulations such as PVC 15, as well as impacts on blocking and hardness depending on the type and dosage of coalescent

- Ladder studies characterizing MFFT at various coalescent levels and subsequent LFFT for paints prepared with these levels, including the ability to form a coating on absorbent and non-absorbent substrates at low temperature

- Effects on whiteness and yellowness after exposure in weathering chambers, and gloss retention after aging in low PVC coatings

For fillers, performance data may include:

- Recommended wetting and dispersing additives, suggested dosage levels, and resulting mill-base parameters including viscosity, stability, and settling

- Impacts on key coating parameters, for example:

- For standard fillers, the effect on volume solids, whiteness and yellowness, opacity at various PVC levels, control of the PVC/CPVC ratio, opacity in high PVC formulations, and dirt pick-up

- For functional fillers, intentional performance contributions such as gloss or sheen reduction curves at defined PVC ranges, improved scrub resistance, reduced coating density, increased hardness, enhanced opacity, or the ability to extend titanium dioxide pigments

For defoamers, technical data must be detailed to support ease of use, operational efficiency, and avoidance of defects. Necessary information includes:

- Type of chemical base such as silicone-based, silicone-free, mineral oil-based, or polymer-based

- Point of addition such as full dosing during the grind stage, partial dosing across grind and let-down stages, or use with an assist defoamer

- Required shear forces for incorporation, which may depend on equipment capacity when production uses a dissolver with a low-power motor

- Duration of incorporation

- Recommended dosage levels for specific PVC ranges

- Impact on gloss in low PVC high-gloss coatings

- Foam collapse performance in stir tests, roller tests, or repeated tests after storage stability assessments

- Impact on coating defects and suitability for clear varnishes

- Compatibility recommendations for specific polymer dispersions

For each raw material, comparisons with competing materials should be provided along with performance assessments in various formulations. These may include comparisons across different coating types such as interior paint, exterior paint, wood and trim coatings, roof coatings, cabinet enamels, or parquet varnishes. They may also include differences in formulating practices between regions such as the United States, Canada, and the European Union, which may use different raw materials based on regional availability. Additional comparisons may cover different PVC ranges depending on the type of paint.

Such technical materials allow formulators to choose raw materials for testing with greater confidence and to evaluate performance using structured case studies. This enables formulators to translate those findings into their own formulations more easily and with better understanding.

Conclusion

Preparing a formulator for the independent selection of raw materials is a long-term process that requires learning both theory and practice. On the theory side, it is necessary to understand legal and environmental regulations, formulation habits in the market, and consumer expectations. In practice, formulators must continually build experience through testing, consultations, analysis of case studies, and participation in webinars and technical conferences to deepen their knowledge from specialists who provide recommendations for the effective use of raw materials in latex paint formulations.

Mastering the ability to navigate technical data and analytically interpret test results becomes much easier when the formulator has access to clear and understandable application studies. These materials should be based on realistic formulations that are familiar to the formulator and use methods that are standard in the paint and coatings industry for determining parameters of liquid paint and finished coatings. This type of technical documentation is an essential part of introducing raw materials to the market and supporting their conscious use, especially in times where resource optimization and cost management are so important for the final product, such as latex paints.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!