Circular Reuse Strategies for Sustainable Paint Recycling

In this article:

- Circular reuse in paint manufacturing

- Waste minimization in production streams

- Sustainable resource recovery pathways

- Reuse of off-spec and expired materials

- Economic impact of circular paint recycling

Understanding the Meaning, Purpose, Use and History of Coatings

Coatings have been a part of our society for over 5,000 years. The use of coatings has been found in constructions older than the Hanging Gardens of Babylon and the Pyramids. Formulations, technology, ingredients, and style of manufacturing kept changing. What did not change was the purpose, performance, and requirement of the coatings. Coatings enhance durability, multiply the lifespan, and increase the beauty of any surface they are applied to. Hence, the paint and coatings industry provides one of the most sustainable solutions to the world by minimizing replacement cost, time, and process. This reduces stress on fuel, water, labor, natural resources, and the environment, resulting in lesser extraction of resources, mining, polluting, and a lower carbon footprint.

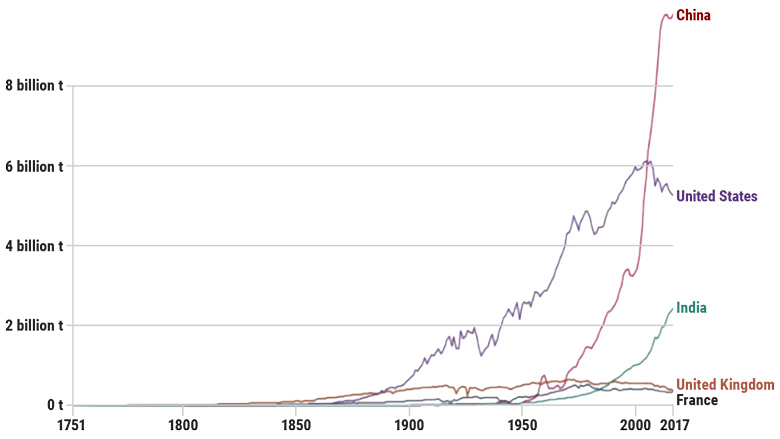

There is a direct relationship between coatings and environmental sustainability through their function of increasing life, enduring strength, and providing weatherability to a bridge, ship, aircraft, electronics, machinery, or a home.

Ingredients for Durability and Challenges to Manufacturers

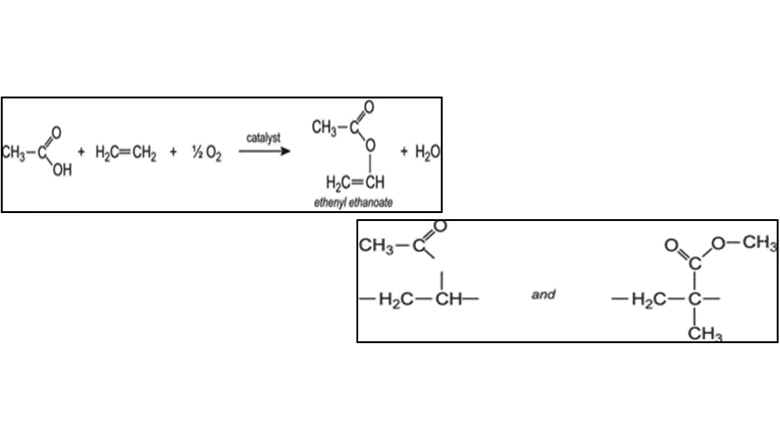

In order to stay in their top game of providing functional and application properties, coatings went through several formative changes and evolved over a period of years to fit cost and long-lasting demands. With the use of hydrocarbon and molecular engineering, it was possible to get the toughest coats. The challenge of cost and durability is solved until we get into the issues of biodegradability, greenhouse effects, and cradle-to-grave responsibilities. This increased demand for coatings that were lower VOC, easy on humans and the natural habitat, and eco-friendly. Coatings' major function is to fight the ecosystem and keep substrates safe, yet now they have to do so in a friendly manner. No industry has ever faced two opposite challenges at the same time.

With chemistry, everything is possible, and with the right ingredients, we attain replacements and move toward a greener, healthier pathway. Laws that control what goes in paint cans help create safer and less toxic formulations.

However, no matter how good and friendly coatings are with the ecosystem, they still could never become 100% biodegradable, which could defeat their purpose. Hence, management of unusable and unsalable items, and items created during production, is our topic of discussion today. These items still need to be put to an environmentally stable solution.

Economic Aspects of Sustainability

This is an economic aspect of sustainability. How has the economic environment around us changed, and where has this change led us?

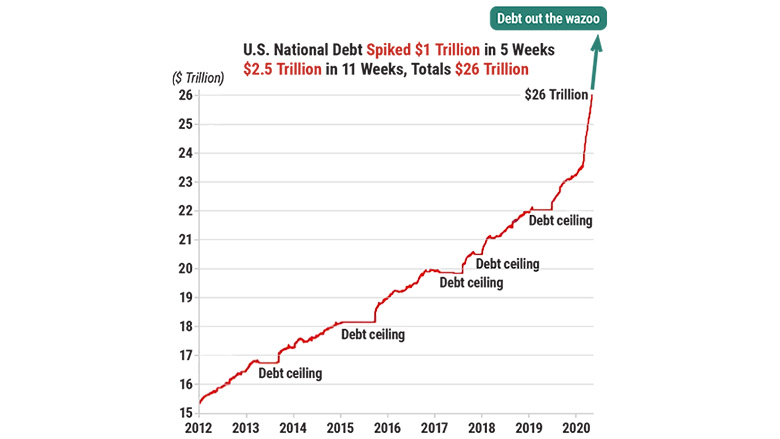

We are in the era of abundance. Financial times under which everything is possible. The economic era is equipped with fiat currencies, empowering unlimited access to extract natural resources and create easy lifestyles. The correlation of technology with the economy eventually affects ecology. Creation of currencies, if not supplemented with sufficient assets or goods, could cause inflationary situations.

Circular economy is a solution not just for fighting carbon footprint but for serving as an inflation hedge, stabilizing prices, and ensuring availability in communities of need.

Challenges and Struggles

We currently land bury or fuel blend over 95 % of paint waste, with marginal projects in place.

These are two places where waste generation takes place:

Household and Stores

Recent developments in public, private, association, and government partnerships create programs like PaintCare, Paintback, and ProductCare. Transporting and recycling companies collaborate with collection centers and bring items back from the waste stream into product management.

Yet a major part still ends up in fuel burning and land burial. Only 20 to 25% of states are covered with HHW or independent HHW recycling programs, and the majority of solvent-based or hazmat coatings end up in fuel blending. Steady regulation and program updates help, but generation is many times higher than containment.

Industries and Raw Material Producers

Changes in formulations, acquisitions, liquidation, bankruptcy, ownership changes, brand transitions, legal shifts, and natural calamities all generate unsalable and unusable inventory. Routine operations also create off-spec materials, wastes, expired items, and returns. Retail packs may move through donations, auctions, or discount channels, yet the majority still end up buried or fuel blended.

Circular Reuse as Waste Minimization

Circular economy diagrams show waste generated at all stages:

- Extraction and production of raw materials

- Paint production

- Distribution and stores

- Application

Items collected from these points can be formulated into products for use. Beyond the environmental benefits, charitable projects and corporate social responsibility efforts further decrease fuel blending and landfill dependence.

A Million-Dollar Question: How to Convert Waste to Reuse?

- Identify — Identify items that could be used and collect them intentionally as product.

- Categorize — Categorize all identified and collected items as product.

- Store — Move items out of waste areas and store them with usable or salable goods.

- Label — Label these items as product. No waste, scrap, or disposal labels should be used.

- Reuse (Circular) “As Is” — The final step is circular reuse “as is,” without changing the form, burning, or extracting components. When reused as originally intended, the item becomes a product, not waste.

This five-stage process changes both the destiny and definition of the waste stream.

Glimpse of US 40 CFR — Exception to the Rule

EPA language supports the above concept:

“Is the HSM used directly as an ingredient in an industrial process or as an effective substitute for a commercial product?” If YES, the HSM is not a solid waste per 40 CFR 261.2(e).

“Is the HSM processed to reclaim a useful product, and is the HSM either a commercial chemical product, a characteristic byproduct, or a characteristic sludge?” If YES, the HSM is not a solid waste per 40 CFR 261.2(c)(3).

Items that Can Be Reused

Process After Receiving

- Sorted — Items are sorted by solvent and resin grouping, density, compatibility, color, sheen, and viscosity.

- Bulked — Sorted items are bulked into 1,000 L IBC totes for use in production.

- Used — Items are used in production batches up to 30% to 80% with other chemicals.

All items created are sold into markets for use and have positive utility and value.

EPA Promotes Recycling Over Land Burial and Fuel Blending

The EPA offers guidance on reducing and reusing materials at https://www.epa.gov/recycle/reducing-and-reusing-basics, and the Federal Trade Commission outlines charity guidelines at https://www.consumer.ftc.gov/articles/0074-giving-charity.

Fuel blending burns materials but does not recover pigment or resin functionality. Distillation recovers solvents but still produces waste. True circular economy occurs when materials move as is into new batches of production.

- It is recycling when leftover paint is collected and transported for land burial but it still dumps waste into the ground, which confirms but postpones the damage. Items move as waste here. This is not circular reuse but it is recycling.

- It is recycling when solid and liquid waste is used as fuel with burning credits. However, pigments, resins and solvent functionality are not recovered for circular use, so the materials still move as waste.

- It is recycling and circular economy when solvent or water is extracted through a distillation process. The outgoing materials still become waste.

- However, when items are moved as is and used as they are in production batches for coatings, the process becomes circular economy and the materials move as products.

Industry, Associations, and Contributions

Paint factories, associations, consultants, and governments form partnerships to support paint recycling. Associations serve as platforms for industry ideas and solutions that inform government policy.

Advantages of Waste Minimization

Circular reuse of paint and coating materials not only protects the environment but creates a sustainability balance across the industry. Here are some advantages:

- Lower carbon footprint

- Reduced greenhouse effects

- Less waste in paint companies

- Lower extraction of natural resources

- Anti-inflationary effects

- Increased affordability in communities of need

- Greener, healthier, sustainable environments

If it is not well done, then it isn’t over yet.

Learn more about sustainability efforts across the industry on our Sustainable topic page.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!