Performance of Durable Fluoropolymer Coatings

Fluoropolymer coatings are known as highly durable coatings that can maintain their initial performance for a long period. Poly(vinylidene fluoride) (PVdF) was widely used as a first-generation fluoropolymer coating, however, because it should be cured above 200 deg C, the application area is restricted to coil coatings, etc. In the 1980s we developed a copolymer of fluoroethylene and vinyl ether as a solvent-soluble fluoropolymer, which is called FEVE (poly-fluoroethylene/vinyl ether). FEVE could be used on-site for applications such as heavy-duty architectural and aerospace coatings, as well as for oven-baked coatings. Many reports concerning their durability have been published.

When these fluoropolymer coatings were applied as protective coatings, they were used as a topcoat for coatings systems, and they protected under-layer basecoats and substrates from UV attack. More than 20 years have passed since FEVE coatings were commercialized, and their performance on many bridges and skyscrapers has been proven.

Because of their unique properties, it is possible to use FEVE-based coatings in applications that are difficult for other fluoropolymer coatings. These new applications have also been developed.

Structure of FEVE

FEVE can be synthesized by solution co-polymerization of fluoroethylene and vinyl ether. The fluoroethylene unit provides weatherability and durability, and the vinyl ether units give properties essential for coatings like solvent solubility, transparency, gloss, hardness and flexibility. From the viewpoint of solubility in organic solvents, chlorotrifluoroethylene (CTFE) was co-polymerized as fluoroethylene (Figure 1).

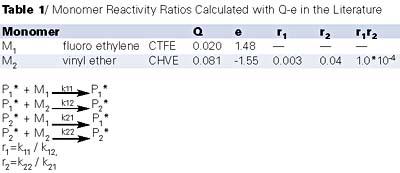

The FEVE copolymer has a high regularity of alternating fluoroethylene and vinyl ether moieties, and this structure is decided by monomer reactivity ratios. When CTFE (fluoroethylene) and CHVE (vinyl ether) react, reactivity ratios (r1, r2) can be calculated from Q and e values listed in the literature1 (Table 1).

Furthermore, polymers having hydroxyl functionality could be easily prepared by co-polymerization of hydroxy-alkyl vinyl ether, and make it possible to be crosslinked with curing agents such as isocyanate and melamine.

FEVE Coatings as Bridge Topcoats

Weatherability has been evaluated for FEVE coatings by many types of accelerated tests, and the results showed its excellent performance.3 However, lifetime of coatings is influenced by many factors, and it is very important to evaluate the durability of a coatings system on actual constructions. Figure 2 shows a bridge located along the seaside that was coated by FEVE and chlorinated rubber 11 years ago. While the area coated by chlorinated rubber has lost its original color, and severe rust was observed, the FEVE coating has kept its original appearance and anticorrosion property. As for other bridges coated by both FEVE and alkyd paint, performance of the topcoat was also evaluated, based on "Standards for evaluation of paint film" published from the Japan paint inspecting association (Figure 3). These test results showed that a heavy-duty coating system, using FEVE topcoat, kept the initial anticorrosion performance much better than the alkyd paint even after more than 13 years exposure.

Application Areas for FEVE Coatings

On-Line Coatings

As mentioned above, FEVE is an alternating copolymer of fluoroethylene and vinyl ethers, and it has 50 mol% fluoroethylene units and 50 mol% vinyl ether units. Even if other types of vinyl ethers are co-polymerized, this almost complete alternating structure is kept, and FEVE has excellent durability. Therefore, it is possible to design polymers with various Tgs and a number of OH functionalities by adjusting the side-chain structure of the vinyl ethers and their ratio.

Clear Coating

Because of the transparent and colorless properties, FEVE can be used as a clear coating and provides high durability and a smooth surface. However, when it is used as a clearcoat, UV absorbers must be included in the formulation. Since UV light can penetrate and transmit through the FEVE layer (Figure 6), if UV absorbers are not used, or are of insufficient quantity, UV light can decompose the under layer and cause peeling or blistering to occur between the top clear layer and the under layer. In using UV absorbers, it is important to consider the UV absorption range and the miscibility of the absorber with the FEVE film.

Emulsion-Type FEVE

In recent years, waterborne fluoropolymer coatings have been developed and their sales are increasing mainly in architectural application. Waterborne FEVE can be synthesized by emulsion co-polymerization of fluoroethylene and vinyl ethers; vinyl ether-type macro monomers, having hydrophilic units, were also introduced to stabilize the emulsions. Using a particular hydroxyalkyl vinyl ether, emulsions with OH functionality could be prepared.4

Waterborne FEVE is mainly used as a one-component paint, but because of cost issues, the application area for these paints is restricted. These problems could be solved by using a blend of FEVE emulsion with other resins. A blend with an acrylic emulsion was studied, and the FEVE emulsions exhibited good compatibility and provided a transparent, colorless film (clear coating). It is also possible to prepare high-gloss pigmented coatings.

In addition, coatings from blended emulsions exhibited better adhesion to the substrate than FEVE. When waterborne FEVE, having OH functionality, was applied without hardener, adhesion to some substrates was insufficient. However this property could be improved by using other functional groups like carboxylic acid that the acrylic emulsion included. This result showed that it is possible to design coatings, in which weather resistance and cost is between that of fluoro- and acrylic polymers.

Conclusion

Solventborne FEVE (copolymer of fluoroethylene and vinyl ether) had been used for many construction applications, and its high durability was proven by follow-up research of actual bridges that were coated more than 10 years ago. FEVE, being soluble in solvents, could be cured under a wide rage of baking temperatures, and also provides high gloss or clear coatings.Waterborne FEVE has excellent weatherability, and it can be blended with acrylic emulsions. This blended emulsion makes it possible to design coatings with both weather resistance and cost between that of either a fluoro- or acrylic polymer.

This paper was presented at the 7th Nurnberg Congress, European Coatings Show, April 2003, Nurnberg, Germany.

For more information, e-mail Akihiko-Asakawa@om.agc.co.jp

References

1 Greenley, R.Z. Polymer Handbook 3rd Ed., 1989; p267.2 Ishida, T.; Effect of Monomer Sequence on Polymer Durability in Copolymers of Chlorotrifluoroethylene with Alkyl Vinyl Esters or Alkyl Vinyl Ethers; Reports Res. Lab. Asahi Glass Co., Ltd., 51 2001.

3 Asakawa A.; Lumiflon, the High Performance Fluoropolymer, Preprints of Asia Pacific Coating Conference Paper 2002.

4 Yamauchi, M.; and Hirono, T. Waterborne Crosslinkable Fluoropolymer for Paint Use, Preprints of the Fluorine in Coatings II Paper 24 1996.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!