Appearance Control in the Automotive Industry

The paint finish of a car plays a major role in how customers perceive the car’s quality. The ideal look would be mirror-like: high gloss and perfectly smooth. But as we all know, there are limitations in the paint properties, process capabilities and, most importantly, the amount of time and money that can be spent to improve the finish.

As a result, each automotive company defines their own standard to specify an acceptable finish. Especially important is uniformity of the finish. Harmony between the horizontal and vertical panels is critical. Equally significant is how add-on parts such as bumpers, spoilers and decorative trim match the adjacent body panels. Differences are especially obvious on models with panels having very tight fits to each other.

In the past the appearance was described with a variety of terms such as glossy / brilliant or dull – wet look or snap – orange peel – smooth.

wave-scan DOI is the instrument of choice

- Easy to use as a production QC tool – small and lightweight

- Curved and flat parts can be measured

- Reliable – no maintenance problems

- Worldwide repair / calibration service

- QC reports are easy to set-up and can be modified in Excel[R]

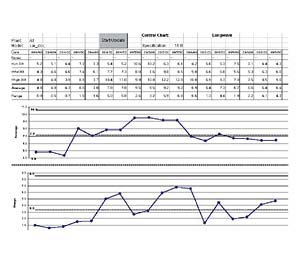

- For routine process control, company specific scales (LW – SW – DOI or GM-Rating DOI or Ford QMS scales or Chrysler QMS scales) can be charted to give a quick overview or show the trend for specific colors (see graph on previous page).

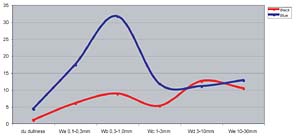

- Measurement results help to understand the appearance! The wave-scan DOI measures different structure sizes and graphically illustrates the “structure spectrum” of the surface finish.

The shorter waves (du, Wa, Wb) give us the impression of good or poor distinctness of image (DOI) and are mainly influenced by material properties, substrate influences (steel vs composites, influence of “rough“ e-coats, primer or basecoats) or process parameters (flash off time, sanding between layers).

For more information, phone BYK-Gardner at 800/343.7721 or fax 800/394.8215.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!