High-Performance Coatings Based on Hybrid Organic-Inorganic Polymers

The industrial coatings market is undergoing substantial changes due to environmental regulations, where cost-effective nanoparticle-modified coatings could represent competitive products. This paper presents the applications of polybranched hybrid organic-inorganic coatings. Nanoparticle-based dispersions made by sol-gel method have been prepared, and the particle surface was modified to suit mixing with a variety of polymer materials.

By a suitable choice of raw materials, stabilizers as well as coating-forming additives and other types of additives could be prepared. Such stabilizers or other additives give a broader application range than for the currently known mono-functional stabilizers and can be used in lacquers, paints, curable plastics and thermoplastics. The various applications of these products will be illustrated for wear resistance, photostability, barrier layers and additives for retarding degradation.

The design of hybrid organic-inorganic hybrid nanocomposites from functional nanobuilding blocks has been reviewed by Sanchez et al.1 Silica particles with uniform diameter and a mean size of 400 nm have been prepared by sol-gel and have been further modified by amines, isocyanate or epoxide ring groups.2 The degree of substitution reached after modification of these groups was ca. 0.056 mol%/g of silica. These materials were mixed with epoxy resin to prepare composites with various degrees of homogeneity.

Transparent and abrasion-resistant hybrid organic-inorganic coatings have been prepared on plastic substrates like polycarbonate.3 The coatings were based on organic components (3-isocyanatopropyltriethoxysilane functionalized DETA and IMPA) and inorganic components (TEOS and TMOS) that were further hydrolyzed through a sol-gel process.

The application of nanostructured coatings with high wear resistance and superior photostability/ weatherability has recently been focused on in our laboratory.4 Epoxy coatings modified with nanoparticles show high weather resistance (Figure 1) and high scratch resistance (Figure 2) compared with non-modified epoxy resins. This technology has high industrial applicability due to a combination of improved properties and low cost. Industrial applications have been considered in coatings with improved wear resistance and light stability for industrial flooring, wear-resistant hydrophobic coatings for information and communication technology (infocom), new coatings for thermoplastics, new coating formulations (solventborne and waterborne coating formulations), nanocomposites with selective barrier properties for gases and production of nanofillers.

TEOS grafted silica and alumina nanoparticles have been used to obtain transparent polyacrylate nanocomposite coatings.5 The nanocomposites showed increasing wear resistance with a filler content between 15 and 50 wt%.

The synthesis of organic-inorganic (hybrid) polymers to be used as binder systems for functional masonry paints has been described by Posset et al.6 Commercially available polymers were covalently reacted with organofunctional silanes and subsequently crosslinked via sol-gel.

A review on hybrid polymers as nanobuilding blocks in organic-inorganic hybrid nanocoatings was given by Haas et al.7 One type of nanobuilding blocks is based on organically modified silicon alkoxides and/or functionalized organic oligomers/polymers. Coating formation is done by the formation of an inorganic network by polycondensation reactions (e.g., Si-O-Si bond formation) in a first step, followed by organic crosslinking (thermal curing at 80-180 °C or UV processing). Another type of nanobuilding blocks uses the silylation of organic polymers, with subsequent hydrolysis and polycondensation reactions of the silanized units.

Nanobuilding Blocks Based on Organic-Inorganic Hybrid Polymers

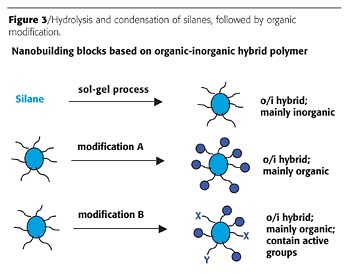

A different type of nanobuilding blocks can be obtained by organic modification of sol-gel products. This method provides cost-effective crosslinkers or binders for organic-inorganic hybrid nanocoatings, especially when the nanobuilding block mainly consists of inexpensive organic modifiers. Another advantage is that both the sol-gel process and the organic modification can be performed in a single process in standard reactor equipment. Figure 3 shows the principle processes of hydrolysis and condensation of silanes, followed by organic modification. Silanes containing amine moieties are particularly suitable for this process, but also silanes containing hydroxyl groups, sulfhydroxyl groups and other reactive groups can be used.

During organic modification, functional groups can be introduced, which increase the degree of crosslinking of the cured coating. Coatings that have a high degree of crosslinking generally exhibit higher scratch and wear resistance than coatings with a lower degree of crosslinking. Additionally, functional groups introduced during organic modification can improve adhesion between a coating and a substrate together with the weatherability of a coating.

Experimental

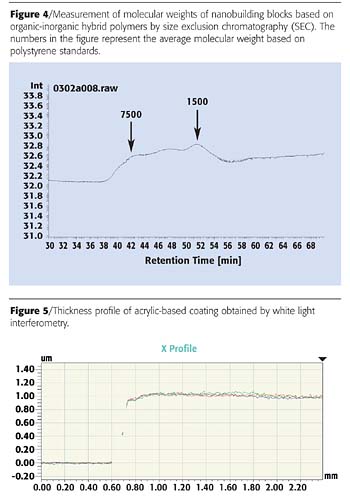

Molecular weights of nanobuilding blocks based on organic-inorganic hybrid polymers were measured by size exclusion chromatography (SEC). A series of three SEC columns based on 5µm particles and pore sizes from 10,000 Å to 100 Å was used together with a standard pump and a refractive index detector. Cyclohexane was used as mobile phase, and sample solvent and molecular weight determination were based on polystyrene standards. Typical molecular weights of nanobuilding blocks based on organic-inorganic hybrid polymers as described in this paper are in the range 1,200-7,500 g/mole, as shown in Figure 4.Typical viscosities measured at a shear rate of 30 s-1 were 20,000 mP·sec at 25 °C and 200 mP·sec at 100 °C. Based on this viscosity profile, solvent-free applications at moderately elevated temperatures could be possible. As an alternative, ambient temperature applications with a minimum of solvent and therefore with low VOC emission could be possible.

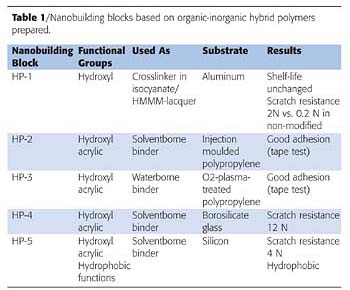

Four different nanobuilding blocks based on organic-inorganic hybrid polymers were prepared and used in one application each. Table 1 gives information on these nanobuilding blocks.

Results and Discussion

A solution of 77% HP-1 in xylene was mixed into a commercially available lacquer based on polyacrylate/blocked isocyanate/hexamethoxymethymelamine (HMMM). The modified lacquer contained 38% HP-1 and had the same viscosity, transparency and shelf life as the unmodified lacquer.The modified lacquer was applied to aluminium sheets by bar coating. The coating was cured in a circulating air oven at 250 °C for 5 minutes. The scratch resistance measured with an Erichsen pen was 1.5 - 2.0 N (compared with 0.2 N measured on unmodified lacquer).

A solution of 60% HP-2 in xylene was applied to the surface of an injection-molded polypropylene homopolymer sample. No pre-treatment was applied. The coating was cured by heating up the sample surface at 155 °C for 5 minutes and afterwards keeping the whole sample at 60 °C for 18 hours. Standard tape testing showed good adhesion of the cured coating on the polypropylene surface.

Neat HP-3 was applied on a borosilicate surface and cured in a circulating air oven at 250 °C for 10 minutes. The thickness of the high transparent coating was 1 mm. The pencil hardness measured with Erichsen pen was 11 - 12 N.

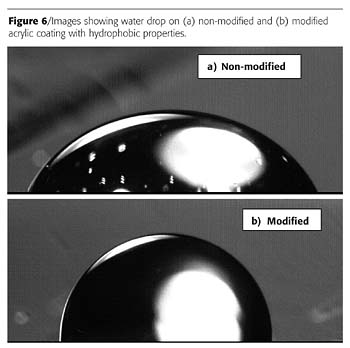

An acrylic lacquer based on 11 wt% of HP-4 in xylene was designed for applications in microelectronics where parts of silicon wafers need to both be protected against wear and at the same time to be highly hydrophobic. The coating thickness was adjusted to 1 µm or below by a combination of the viscosity of the lacquer and the parameters of spin coating method (speed rate and spin time). The coated silicon wafers were cured at 250 ºC for 2 minutes in a furnace with air circulation. Figure 5 shows a typical thickness profile obtained by white light interferometry. The coating thickness is very homogeneous and equal to 1 µm. The contact angle between a water droplet and the coated silicon wafer was 90º, which is 26º higher than on pure acrylic.

Conclusions

Nanobuilding blocks can be obtained by organic modification of sol-gel products. This method provides cost-effective crosslinkers or binders for organic-inorganic hybrid nanocoatings, especially when the nanobuilding block mainly consists of inexpensive organic modifiers.Commercial lacquers can be modified with nanobuilding blocks based on organic-inorganic hybrid polymers. No changes in transparency, viscosity or shelf life of the lacquer have been observed. Cured coating based on modified lacquer show clearly improved scratch resistance.

Nanobuilding blocks based on organic-inorganic hybrid polymers make pre-treatment-free coating of injection molded polypropylene samples feasible. Good adhesion of the coating can be achieved.

Coatings of 1 mm thickness with high transparency and high pencil hardness can be obtained by application of neat nanobuilding blocks on borosilicate glass.

Thin-film coatings on silicon substrates can be obtained by spin coating using diluted solutions of nanobuilding blocks. Highly hydrophobic surfaces can be obtained.

For more information, contact Christian Simon at christian.simon@ sintef.no.

Acknowledgments

The authors thank Jest Beylich for the preparation and application of the lacquers, Kjell Olafsen for providing viscosity results, Britt Sommer for SEC-measurements and Martin Fleissner for white light interferometry measurements and optical microscopy.

References

1 Sanchez, C.; Soler-Illia, G.J.; Ribot, F.; Lalot, T.; Mayer, C.R.; Cabuil, V. Chem Mater. 2001, 13, 3061-3083.

2 Kang, S.; Hong, S.I.; Choe, C.R.; Park, M.; Rim, S.; Kim, J. Polymer 2001, 42, 879-887.

3 Wen, J.; Jordens, K.; Wilkes, G.L. Mat. Res. Soc. Symp. Proc., 1996, 435, 207-213.

4 Simon, C.; Männle, F.; Redford, K.; Gaarder, R. Nano Structured Coatings with High Wear Resistance and Superior Photostability. Paint and Ctgs. Ind., 2003, 19(8), 60-67.

5 Bauer, F.; Gläsel, H.J.; Decker, U.; Ernst, H.,; Freyer, A.; Hartmann, E.; Sauerland, V.; Menhert, R. Prog. Org. Coatings, 2003, 147-153.

6 Posset, U.; Rose, K. Innovative Hybrid Coatings for Facades. Organosilicon Chemistry V: From Molecules to Materials, Auner, N.; Weis, J. (eds.) 2003, Wiley-VCH Verlag GmbH & Co., KGaA, Weinheim, Germany, 645-649.

7 Haas, K.H.; Rose, K. Rev. Adv. Mater. Sci. 2003, 5(1), 47-52.

This paper was presented at the 8th Nürnberg Congress, Creative Advances in Coatings Technology, April 2005 in Nürnberg, Germany. The Congress is sponsored by FPL, PRA and the Vincentz Network.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!