Fluoroadditives: Antiblock Characteristics in Architectural Paint Systems

VOC Reduction and Block Resistance

The regulatory push to reduce the amount of volatile organic compounds in waterborne architectural paints has given rise, indirectly, to “softer” resin systems. This is one (but not the only) approach to generating coatings whose dispersions will coalesce upon evaporation to give a functional film using reduced quantities of solvent, or no solvent at all. These softer resin systems, especially in the earlier stages of drying and curing, have a strong tendency to adhere to one another, or “block.” This tendency is most strongly exhibited by coatings at the higher end of the gloss scale; this type of coating was the focus of the study. The “flat” or low-gloss paints have an uneven surface, created by the larger particles that they contain that lessen intimate contact between the surfaces and, therefore, reduce blocking behavior. The marketplace is also demanding coatings with less odor, and the coalescing solvents in a latex paint are, clearly, one source of that odor.

Key Variables in the Study

Additives

One approach to improving the block resistance of a coating is to introduce a surface-active agent that will bloom to the top (the air interface) of a film as it dries/cures. The surface-active material functions as a release layer that interferes with the intermingling of the resin layers of two films that are in contact with one another. Commercially used systems include silicon-based materials, waxes and fluorinated additives, and the effects of these additives are measured and compared in this study. In the statistically designed study we chose two wax emulsions, two silicones and two fluorinated additives. In each coating we bracketed the concentration with a “high loading” and a “low loading” using the manufacturer’s recommendations, while keeping track of the absolute net cost per gallon of paint. We were seeking the most cost-effective remedy to provide the needed improvement in performance. The additive levels are delineated in Table 1.Coatings

The coatings used in this study were a variety of commercially available (North America) waterborne latex paints described as semigloss or “high gloss.” The samples included interior and exterior coatings, some advertised as being block resistant, from the very economical to the most costly paints in the marketplace. The resin systems in these coatings were all variants of an acrylic or vinyl-acrylic nature, or a physical blend of the two. A total of 20 paints was studied.

Method

The analytical method used for this study was a variant of ASTM D 4946-89. Fresh coatings were applied (wet thickness 7 mil) on matte-finish polyester panels. After either one or seven days of air drying time, the castings were cut into 3.8 cm squares, which were placed in a 50 deg C oven for 30 minutes and pressed together by a 1 kilogram weight that rested atop a #8 rubber stopper. This generated approximately 1.8 psi on the specimens. After removal from the oven and equilibration for 30 minutes at room temperature, the films were peeled apart and measured on the qualitative scale shown in Table 2.

We measured block resistance after one day, and again, after seven days of drying/curing under controlled temperature and humidity conditions. The aim was to observe block resistance as a function of time.

Results and Discussion

The Method

One-day and seven-day block resistance was measured on a total of 20 paints. Of these 20 paints, eight of the poorer performers (that is, one-day block resistance less than a value of 5) were selected for more intensive study to see how they responded to the presence of additives. It was found that a total of six replicates for each paint and additive level were needed to achieve the desired level of statistical confidence in the data. We found that the 7day method had improved reproducibility and repeatability (in roughly equal measure) compared to the 1day method. Also, it was observed that the 1day method is significantly less repeatable (i.e., variation within a set of observations) by comparison to its reproducibility.It was found that paint type, additive type and additive loading level were significant factors in the 7day method. It is interesting that for the 1day method, the loading had no statistically significant effect. This indicates that there are changes in the film as it dries/cures that could bring more of the additive to the surface to change blocking performance as a function of time.

The resin type had the greatest effect for both methods, and was most marked for the 1day data. Additive type had comparable effects for both methods.

The Coatings

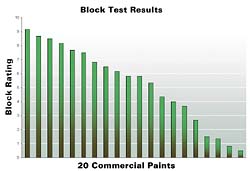

All resin systems were acrylic, vinyl acrylic or mixtures of the two, and all paints were labeled by the manufacturer as either semigloss or high gloss. Of the 20 paints tested, the average block rating was 5.25, with interior paints averaging about one full unit higher (5.7 v. 4.6) in performance compared to exterior paints. Forty percent of the paints tested rated less than a “5” in the block test. The results of blocking performance for these commercial paints are shown in Figure 1.Figure 1 indicates that the paint formulation itself is key to the block resistance of the coating. Cost did not seem to be a factor correlated to block rating as shown in Figure 2.

Further, the responsiveness (change in block resistance as a function of additive and additive level) of a particular paint to a particular additive was variable. The analysis presented in this report is based on data collected from eight paints selected from the initial screening work. These eight paints were selected on the basis of their weaker performance in block resistance.

Blocking Performance

Blocking was measured as a function of additive type and additive level. A total of six additives were tested, each at a high and low level based on manufacturers’ recommendations, in eight waterborne architectural coatings.The results for the addition of Zonyl FSP at 0.05% to the eight weakest performing paints is shown in Figure 3.

Zonyl FSP improved blocking by at least 2.5 units and up to 7 units. Figure 4 shows an example of an initially poorly performing paint (left side) and the improvement with Zonyl FSP added (right side).

The variability in coating responsiveness indicates the interaction of the additive with the components of the coating formulation.

Additive Results

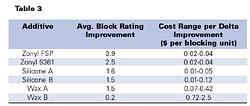

When all three types of additives are compared, the largest blocking improvements on an absolute scale were clearly attributable to fluorinated additives, with an average improvement of 2.5 on the blocking scale at 0.05% additive level. The silicone-based additive systems were often as effective as the fluorinated additives on a cost basis. An improvement of 2.5 on the blocking scale was achievable in some cases with this type of additive, but the average improvement was 1.5 units on the blocking scale. The wax additives gave blocking results that were widely variable, that is, sometimes effective with an improvement of 2 units, but sometimes with no effect on blocking. A clear advantage of the fluorinated additive was its ability, on an absolute scale, to create the largest improvement in block resistance.

Data was also compiled on a “cost per delta” basis, as cost is almost always a driving force for the customer. This value (or range) is computed as the cost (per gallon) necessary for a particular additive to raise the blocking performance by one (1) unit on the blocking scale. It is a measure of the cost effectiveness of the additive in a particular coating. Data for blocking performance and costs per delta improvement in block rating are shown in Table 3. The fluorinated additives consistently gave a greater improvement in a narrower range of additional cost.

Appearance

Anti-blocking additives, since they tend to gather near the top surface of a film, can change the appearance of a film (the gloss level). Our gloss measurements were taken at 65 deg with a BYK-Gardner instrument. In general, the type of paint (semigloss or high gloss) was the most important variable. Waxes noticeably lowered the gloss reading, particularly in high-gloss paint. Silicones moderately lowered the gloss in both types of paints. Fluorinated additives had very little impact on the gloss measurement in a semigloss paint and no impact in high-gloss paint.

Summary

In this study, the block resistance of waterborne architectural paints was studied using a variant of ASTM method D 4946-89. The tests were statistically designed to determine the relative effects of a number of commercially available and commonly employed anti-block agents (fluoroadditives, silicones, and hydrocarbon waxes) on the blocking tendency of several paints available in the marketplace.It was found that the fluoroadditives, despite their cost on a per-weight basis, provided benefits that are economically competitive. Further, the fluoroadditives gave results (improved block resistance) that were either not achievable with analogous silicone- or hydrocarbon-based additives or possible only at high levels where either appearance (gloss) or intercoat adhesion of the coatings suffered.

For more information, contact Zonyl Fluoroadditives Technical Service, DuPont Chemical Solutions, Wilmington, DE, 866/828.7009, www.dupont.com/zonyl.

This paper was presented at the 7th Nurnberg Congress, European Coatings Show, April 2003, Nurnberg, Germany.

Pq

One approach to improving the block resistance of a coating is to introduce a surface-active agent that will bloom to the top (the air interface) of a film as it dries/cures.

Pq

The fluorinated additives consistently gave a greater improvement in a narrower range of additional cost.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!