Feldspar and Nepheline Syenite Fillers With a Purpose

Nepheline syenite is a rock composed of sodium and potassium feldspars and nepheline. Nepheline is nominally a sodium aluminosilicate, but potassium invariably substitutes for a portion of the sodium. The amount of potassium in natural nephelines ranges from 2.5 to 10% (3 to 12% K2O) by weight. Nepheline can form only in a geologic environment deficient in silica.

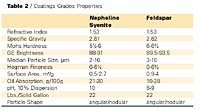

Commercial nepheline syenite deposits, and the products made from them, are consequently free of crystalline silica impurities. These deposits are exploited for their high mineral brightness and low level of dark mineral impurities. Commercial products are made by crushing, dry magnetic separation and milling. Fine-particle-size grades are produced by air classification. In North America, typical nepheline syenite consists of approximately 25% nepheline, 55% sodium feldspar (albite) and 20% potassium feldspar (microcline)1. The basic properties of nepheline and the feldspar minerals are compared in Table 1. There is no North American production of coatings-grade calcium feldspar, which in any event would be less desirable than the sodium and potassium varieties, due to its higher refractive index and specific gravity.

Structure

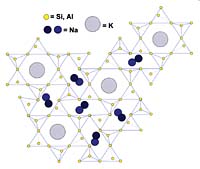

Feldspar mineral structures are based on densely packed four-member rings of silica tetrahedra, making them nearly as hard as quartz. The feldspars used in coatings usually have one of every four Si4+ substituted with Al3+. The resulting charge imbalance is compensated for by sodium, and/or potassium ions.

The nepheline structure is based on six-member corner-linked rings of silica tetrahedra, with apices alternating in direction, forming hexagonal and polygonal voids, as depicted in Figure 1. Al3+ replaces Si4+ in half the tetrahedra, with the charge imbalance compensated for by Na+ and K+. Unlike feldspars, the Na+ can be exchanged with H+, making nepheline less acid stable. Nepheline will gelatinize in HCl, while feldspars will not.

Properties and Uses

The United States is the world¿s third largest producer of feldspar, after Italy and Turkey, with about 800,000 metric tons/year, which is 8.5% of worldwide production.2 The sole North American source of nepheline syenite is Canada, with more than half of the estimated world annual commercial production of 1.2 million metric tons.3 Roughly half of the Canadian nepheline syenite production is exported to the United States. In North America, about 85% of feldspar and nepheline syenite is consumed by the glass (70%) and ceramics (15%) industries. In these applications, the minerals are used for their chemical properties, as a source of alkali and aluminum, rather than their physical properties. The balance of the feldspar and nepheline syenite is used as fillers in coatings, plastic and rubber.2

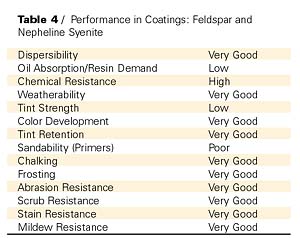

Milled feldspars and nepheline syenite are composed of angular nodular particles, as shown in Figure 2. This shape, with its attendant low surface area, accounts for easy dispersibility, low vehicle demand ¿ lower in fact than would be suggested by oil absorption values ¿ and the ability to achieve high loadings. The shape and size distribution of these filler particles can significantly improve the integrity of dried film through their ability to interlock and pack more tightly and rigidly than smooth-surfaced spherical or nodular fillers.

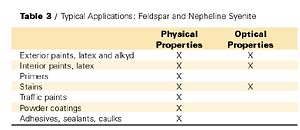

Feldspar and nepheline syenite have very low tint strength, contributing minimal color at high loadings, thus allowing the maximum development of deeptone and pastel colors with minimal colorant. Film reinforcement, chemical stability and resistance to chalking promote high tint and gloss retention on prolonged exterior exposure. A relatively coarse, 4 Hegman grind of nepheline syenite is typically used to achieve the optimal balance of properties. The low refractive index of feldspar and nepheline syenite allows for higher loadings in clear and semi-transparent coatings and stains.

Nepheline syenite is often favored over feldspar in coatings because it is silica-free and an effective alkaline in-can buffer. If an exterior latex coating is sufficiently permeable, however, the nepheline component is subject to attack by acid rain and acidic atmospheric moisture. This can eventually result in the frosting of deeptones. Feldspar is preferred in this case. An application of emerging interest for nepheline syenite is powder coatings. Low resin demand allows for low melt viscosity and high loadings. Improved abrasion resistance and melt flow have been noted.4 Typical applications for feldspar and nepheline syenite are given in Table 3.

Conclusion

Feldspar and nepheline syenite are unique among low-aspect-ratio fillers for the combination of physical and optical properties that they provide for coatings, as summarized in Table 4. These properties are expected to support the continuing growth of filler-grade use despite the predominant focus of production on products for the glass and ceramics industries. This growth will likely favor nepheline syenite because it is free of crystalline silica and related health issues.For more information, contact RT Vanderbilt Co., phone 203/853.1400; fax 203/853.1452; visit www.rtvanderbilt.com; e-mail pciullo@rtvanderbilt.com or srobinson@rtvanderbilt.com.

References

1 Saller, M. ¿In a State of Flux: Feldspar and Nepheline Syenite Reviewed¿, Industrial Minerals Magazine, October 19992 Potter, M.J. ¿Feldspar and Nepheline Syenite¿, Minerals Yearbook: Metals and Minerals 2001, U.S. Geological Survey, 2003

3 Harben, P. Industrial Minerals HandyBook, 3rd Edition, Metal Bulletin PLC, London, 1999

Keegan, N. ed., ¿Feldspar for Filler Applications¿, Raw Materials for Pigments, Fillers & Extenders, 3rd Edition, Metal Bulletin PLC, London, 1999

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!