Synergistic Effects Between Alumina Nanoparticles and Conventional Additives

This paper presents combinations of alumina nanoparticles and specifically functionalized polymeric additives that lead to a remarkable enhancement of coating performance. On the basis of combinations of alumina nanoparticles with surface-active polymers, the enhanced scratch resistance in different coating systems is compared and discussed.

The use of nanoparticles in coatings materials is increasing strongly. One of the main applications is to obtain an enhanced scratch and abrasion resistance. This application area is also interesting for furniture coatings and, of course, for use in flooring coatings. There are several possibilities available when considering a change from an established coating system without nanoparticles to a coating system that contains nanoparticles. The easiest way is the use of a nanoparticle concentrate as an additive for existing coating systems. This additive concept was investigated in different UV-curable coating systems. The objective of this study is to show the performance of alumina nanoparticles with respect to scratch and abrasion resistance.

Materials and Method

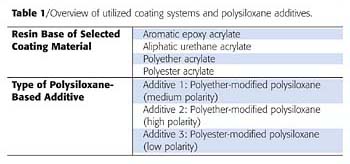

Commercially available UV-curing coatings formulations based on different resin types were used and modified by adding alumina nanoparticle concentrate. These modified coating systems were tested in combination with different polysiloxane-based functional additives.

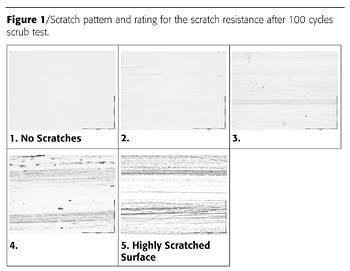

The coating material was applied on PMMA-panels in 25-µm thickness and cured with a high-pressure mercury lamp. The scratch resistance of the coatings was ranked visually after scrub testing (100 cycles scrub abrasion tester, BYK-Gardner) on a scale from 1 (no scratches - excellent scratch resistance) to 5 (highly scratched surface - poor scratch resistance). The ranking was done following the pictures given in Figure 1.

Results

The epoxy acrylate-based UV-coating system was modified with alumina nanoparticles and combined with a polyether-modified polysiloxane additive of medium polarity. The scratch resistance of the aromatic epoxy acrylate-based coating system was tested by a scrub test and checked visually afterwards. The results are condensed in Figure 2.The influence of the incorporation of alumina nanoparticles is shown in the bar chart. By increasing the amount of nanoparticles, the scratch resistance is improved from medium scratch resistance to a fairly good scratch resistance. The left set of columns shows the scratch resistance of the coating system reached by using surface-active polysiloxane-based additive only. There is just a slight enhancement of scratch resistance. This scratch resistance is mainly based upon the enhanced surface slip of the substrates due to the polysiloxane-based additive.

If the combination of alumina nanoparticles and polysiloxane-based additive is used, the scratch resistance is improved dramatically. Just 1.5% alumina nanoparticles in combination with 0.2% surface-active polysiloxane-based additive is sufficient to reach an excellent scratch resistance.

Based on these first encouraging results, an investigation of different coating systems and various modified polysiloxanes was started. The above-mentioned scratch test was used again to screen the performance. The results are summarized in Figure 3.

The four sets of columns in Figure 3 represent the specifically tested coating systems of our investigation. Each individual column represents the average of multiple test results with one formulation, as mentioned in the legend.

Discussion

Despite the fact that the synergistic effect between nanoparticles and our surface-active additives is not yet entirely revealed, we have elaborated a model well in accordance with our results.It is evident that the specific combination of nanoparticles and additives gives the best scratch resistance. The extent of this effect depends on the chemical nature of the matrix and on the additive structure and composition.

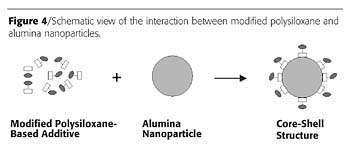

The model highlighted in Figure 4 takes into account three typical interaction possibilities:

The basic idea behind this model is derived from the fact that polyether- and polyester-based polymers are interacting with inorganic surfaces via hydrogen bonding or dipole-dipole interactions. The same interactions are possible between modified polysiloxanes and alumina nanoparticles. By putting alumina nanoparticles and modified polysiloxane-based additives together in one system, the alumina nanoparticles are modified by polysiloxanes, and a kind of core-shell-structure is formed.

As the results with different resin systems show, the polarity fit of the modifying agents with the investigated resin types is very important to get an optimal effect. In the model, the polarity of the modifying agent is important for a compatibilization between the alumina nanoparticles and the resin (coating material). On the other hand, the polysiloxane acts as a distance-keeping structure, so that the nanoparticles are not able to interact with each other but with the matrix. By this principle the boundary phase is enlarged, and so the performance of the alumina nanoparticles is optimized.

Summary

The combination of alumina nanoparticles and suitable polysiloxane additives has a positive impact on scratch resistance in coating materials. The compatibilization with the coating matrix as well as the stabilization of the nanoparticles are evaluated to play a key role in the improvement of scratch resistance. Our first results in different matrices with corresponding polysiloxane additives clearly demonstrate the influence of the additive structure and composition. Our preliminary results can be explained assuming a core-shell-like structure for the additive nanoparticle combination. These kinds of self-organizing structures are well known in other areas, like polymer blends and composite materials. The interaction of the stabilized nanostructure and the matrix of the bulk material give further room for investigation.Outlook

Since the surface modification of nanoparticles has proven synergistic influence on matrix properties, we are going to use this phenomenon with tailor-made additives for various applications. One of our next steps to improve the efficiency further will be the extension to covalently bonded polysiloxanes on different nanoparticle series.For more information, visit www.byk-chemie.com. This paper was presented at the 8th Nürnberg Congress, Creative Advances in Coatings Technology, April 2005 in Nürnberg, Germany. The Congress is sponsored by FPL, PRA and the Vincentz Network.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!