Novel Fluorinated Materials Replace Long Chain Surfactants

Such is the case for a new fluoropolymer technology platform based on oxetane chemistry that is showing potential to enhance surface properties for performance coatings. The technology is unconventional. The innovation process was multi-faceted. And the implications for the fluorosurfactant marketplace are significant, especially given the recent removal of traditional materials due to environmental concerns.

Coating fluorosurfactants are typically non-polymeric, predominantly non-reactive, and based on long C8F17 fluoroalkyl groups. Long fluoroalkyl chains have been considered imperative for peak coating performance.

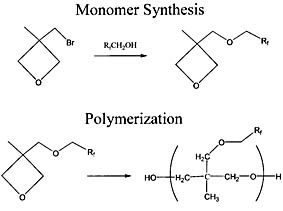

In contrast, the new technology platform rewrites the book in nearly every regard. The structures are polymeric, highly tailorable and based on short fluoroalkyl groups that offer enhanced coating systems compatibility as well as more desirable environmental characteristics (see Figure 1)

By tailoring the polymeric structures, the company says it has been able to achieve the following product benefits.

"With its unique structural features, this new technology platform offers a strong value proposition to the global coatings market," said Dr. Barry Rosenbaum, director, Corporate Technology. "Our PolyFox materials can provide superior flow, leveling and wetting for some applications, and have excellent miscibility in many coating systems. They also offer a wide range of formulating flexibility and a robust processing window."

Rosenbaum emphasized the potential of the platform chemistry to produce a range of products: from water-soluble fluorosurfactants to reactive fluoropolymer resins that participate in radiation-cure coating systems. The reactive chain ends also allow the new fluoropolymer materials to be incorporated into polyurethanes or polyesters, providing excellent fluorine enrichment for targeted surface properties. It is even possible to prepare random copolymers or block copolymers, depending on the end use application (see Figure 2).

Desired performance in flow, leveling and wetting, as well as improved surface properties like durability and stain resistance, may be achieved at material levels anywhere between 100 to 10,000 ppm, depending on the application.

Perhaps most curious is the fact that, as coatings modifiers, these materials perform well despite the moderate surface tension (25-30 dynes/cm) characteristic of short chain structures.

"Our research indicates that modest versus minimum surface tension is not only acceptable, but actually desirable for flow and leveling agents," said Dr. Robert Medsker, PolyFox technology manager. "This concept breaks all the conventional rules that insist long fluoroalkyl chains and very low surface tension are necessary for a successful coating."

OMNOVA Solutions believes that the technology platform is more environmentally friendly than long fluoroalkyl chain materials. Recent U.S. EPA hazard assessments point to concerns over long chain fluorosurfactants and similar chemical structures that degrade and are absorbed into human tissue. Some of these materials have been found to have adverse health effects in animals during laboratory testing. Many of these products have already been withdrawn from the market while others are under close EPA scrutiny.

Recently, several PolyFox products successfully completed EPA new product review for commercial manufacture and sale. The short chain polymeric fluorochemicals are not known to bio-accumulate and the fluoroalkyl ether linkages to the polymer backbone are relatively stable, and thus less likely to biodegrade in the environment.

History

The technology platform uses oxetane chemistry and gives it a novel twist with a fluorinated side chain substituent on the oxetane ring (see Figure 3). Despite the technology's apparent strengths as a fluorosurfactant, coatings modification was not the objective of the original research.The discovery was made in the early 1990s by Dr. Aslam Malik of Aerojet, the aerospace, defense and fine chemicals subsidiary of OMNOVA's former parent company, GenCorp. Aerojet scientists were actually studying substitution of energetic side chains on the oxetane ring and subsequent ring opening polymerization for solid rocket propellant. A number of fluoroalkyl side chains were evaluated that may not have achieved the desired energetics, but certainly sparked an entirely new technology platform chemistry.

"The more we thought about the idea, the better it got," said Malik, director of Research and Development at Aerojet Fine Chemicals. "The excitement was spreading throughout the company, and everyone was coming up with new potential applications for this technology."

Research turned from rockets to marine coatings where the technology was viewed as having excellent potential as an anti-fouling release agent to prevent barnacles from sticking to the bottoms of ships, replacing toxic tributyl tin. By tailoring the fluoroalkyl side chains, excellent fouling release could be obtained and the chain end chemistry was easily compatible with polyurethanes to produce well-adhered, durable coatings. This early work was sponsored by the U.S. Office of Naval Research under the direction of Dr. Kenneth Wynne, and served to establish a solid foundation for the new technology.

By the late 1990s, much of the basic technology platform was in hand and the innovation process began to focus on applications development to achieve some commercial successes. With the spinoff of OMNOVA Solutions from GenCorp, attention turned inward to OMNOVA's commercial decorative products business where the demand for performance coatings in interior wallcoverings, upholstery fabrics and decorative laminates was well-established and where the company had a thorough understanding of the channels to market.

"We play in markets where functional coatings can provide significant differentiation," said Kevin McMullen, Chairman and CEO. "We felt the technology represented a quantum breakthrough in product performance for those markets and proceeded to put a comprehensive R&D program in place to develop leadership coatings that would enhance our competitive edge. Our goal was to create near-term successes in commercializing PolyFox materials for our own products in applications and markets that we know very well. Commercial success would establish credibility for this new technology platform, providing a solid foundation to move into new markets and applications for OMNOVA in fluorochemicals."

During this phase, the material's flow and leveling characteristics became apparent. Focus was expanded into developing a new family fluorosurfactants for industrial coatings and floor care products.

Daikin Alliance

OMNOVA's work drew the interest of Daikin Industries, a leading player in the fluorochemicals market. Japan-based Daikin viewed the technology as a means of driving product innovation and market growth on a global scale. The two companies have formed a strategic alliance to develop and market novel fluorochemical products for surface modification and coating surfactant applications. The alliance brings together OMNOVA's new platform technology with Daikin's expertise in fluorochemistry to offer more environmentally friendly innovative alternative solutions to the estimated $150 million worldwide fluorosurfactant market."Modification of surfaces by the application of fluorine is a strategic area for Daikin. It allows the greatest benefit of fluorochemistry to be realized by our customers and society. OMNOVA's PolyFox technology is a strong technology in this area," said Kiyohiko Ihara, general manager of the Chemical Division at Daikin Industries.

"We recognized that to achieve a fast, global response to market needs we would have to partner with a strong innovative player in the fluorochemicals market who shares our strategic vision of technology leadership," said OMNOVA's Barry Rosenbaum. "With a paradigm-changing technology platform, and several critical initial commercializations behind us in our own decorative products business, we were able to attract the attention of one of the premier fluorochemical companies in the world."

Summary

The road to commercialization of a major technology platform is challenging, with lessons learned along the way. Although the early research started out as a so-called "technology push," the support of the U.S. Office of Naval Research allowed the "rocket scientists" to pursue the technology and to do development on a crucially important end use application, fouling release ship coatings. That work established the broad technology platform for polymeric short chain fluorinated materials that has been strengthened and extended through a series of market-based application developments.Innovation requires a process to transform invention into commercial success. That process drove the transformation from a technology-based to a product-based to a market-based strategy - all the while leveraging and strengthening the capability of the technology platform. Additionally, that process has led to a strategic alliance of two companies in order to move to the next level and drive speedy access to the global marketplace.

The development of platform technologies and leadership products that are innovative, timely and market-based can lead researchers into uncharted territory and challenge conventional thinking. Unexpected discoveries and unusual turns along the way often serve to build a stronger foundation and expose new possibilities. Although much work lies ahead, the broad potential of polymeric short chain fluorochemicals tailored for the needs of the performance coatings industry certainly seems exciting.

Editor's Note

This article first appeared in the Asia Pacific Coatings Journal, Vol. 14, No. 5, 2001. The article is reprinted with permission.

For more information on fluoropolymers, contact Russ Craig, OMNOVA Solutions Inc., phone 803/377.2370; fax 803/377.3542; e-mail inforequest@omnova.com; visit www.omnova.com; or Circle Number 132.

Case Study: PolyFox: Wall-to-Floor Success

The initial applications focus for the PolyFox Technology Platform in the decorative products area was to achieve greater stain resistance in solventborne coatings for vinyl wallcoverings. Scientists wanted to reach or exceed the performance currently available from PTFE-type laminate products.For long-term durability, we quickly learned that the fluoropolymer material needed to be reacted into the coating resin system rather than simply used as a coatings additive. Technology for incorporating the fluoropolymer into polyester resins was developed and found to be compatible with solventborne coatings. Furthermore, during the initial commercial coating trials, the technology's potential as a flow and leveling agent was discovered. Using these fluoropolymer additives, chemists were able to achieve an increase in coatings solids from 40-70%, reducing VOCs significantly while maintaining excellent coating appearance.

OMNOVA's first commercial product using its PolyFox materials in a performance coating was MemErase(tm) flexible, dry-erasable vinyl wallcovering. The product, which replaces traditional dry-erase boards and PTFE-laminated dry-erase films, was introduced in late 1999.

"MemErase wallcoverings caught on quickly in the U.S. with today's trend toward 'think tank' work environments," said Kevin McMullen of OMNOVA. "Our ability to offer the product in colors, preprinted grids and graphics, as well as our success in tailoring the chemistry, allows us to fully exploit the product platform potential for a broad range of settings, including offices, conference centers and hotels."

"This gets back to the tremendous flexibility of the technology," said OMNOVA's Dr. Rosenbaum. "We were able to tailor the fluoroalkyl chain length to get enhanced dry-erase performance with less than 0.2% fluorine content in the topcoat, while achieving about 20% fluorine on the dry-erase surface due to chain end migration. Compare that to the roughly 50% fluorine content throughout the PTFE-type laminates, and one can see what a significant accomplishment this is!"

Following initial validation of the enhanced solventborne coating materials in MemErase wallcoverings, OMNOVA began work on UV-cure coatings with an eye toward increasing durability in its vinyl laminates for furniture. For this application, end group functionality was tailored to provide radiation cure compatible diacrylates using the new fluoropolymer material as a functional crosslinking resin. Target improvements were achieved in scratch, mar, abrasion and coefficient of friction. Also, the coating formulated with the diacrylate demonstrated improved surface gloss, clarity and reduced coating defects. OMNOVA has commercialized a new short chain polymeric reactive fluorosurfactant for UV/EB cure, under the PolyFox TB name. The behavior of the fluoropolymer material as a flow and leveling agent caught the attention of scientists in OMNOVA's performance chemicals division. Development began on new fluorosurfactants for its growing industrial coatings and floor care business.

Floor Polish

"We were very excited by the results we were seeing in coatings modification," said Russ Craig, Floor Care general manager. "And since we were using short fluoroalkyl chain polymeric structures, our timing couldn't have been better. Certain long chain fluorosurfactant products were being removed from several key coatings markets due to environmental concerns and we felt we could offer an excellent alternative."

OMNOVA concentrated its efforts on developing short chain polymeric flow, leveling and wetting fluorosurfactants for the floor polish market, an application the company already served with a line of styrene acrylic polymers. This time, scientists were challenged with tailoring the fluoropolymer structures to make them water soluble, utilizing the wide flexibility of the chain end chemistry.

While short fluoroalkyl side chain groups had been a part of the broader technology platform development effort, now it was the primary focus in order to satisfy environmental requirements for the floor polish application.

Through applications testing of floor polish formulations, we learned that the more environmentally friendly short chain polymeric structures worked well even though the surface tensions were not minimized. Flow, leveling and wetting were excellent with short fluoroalkyl side chains of just CF3 or C2F5, breaking a long held industry paradigm. These structures are far different from the industry standard C8F17. Also, the short chain fluorosurfactants provided a more robust formulating window than conventional materials. This suggested that coating chemists could achieve both performance and processing advantages.

Last October, two short chain polymeric fluorosurfactant products were commercialized for the floor polish market, PolyFox TM and PolyFox VM. "In our floor polish applications laboratory, we confirmed a number of performance benefits beyond those of current products," said Craig. "Foaming was reduced so that in some cases defoamer could be eliminated. Gloss of the polish was increased, mop drag - or the energy required to apply the polish - was reduced, and most importantly, the materials displayed outstanding recoat performance under 'real world' stress conditions of extreme temperatures and humidities. "

OMNOVA is now evaluating next-generation fluorosurfactant products designed to improve performance in hard surface cleaners, floor polish strippers and coatings additives.

In addition, PolyFox products have been developed for amine-cured epoxies and 2K urethane maintenance paints that must apply uniformly to provide protection and durability for industrial environments.

Links

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!