Complex Inorganic Color Pigments: Durable Pigments For Demanding Applications

When purchasing color pigments, color is one of the most important factors in product selection. However, when pigments are needed for exterior durable or high heat coatings, physical and spectral features other than color are an equally important consideration. Heat and chemical stability, UV opacity, hiding power, and infrared (IR) reflectivity are important attributes in such coatings. Complex inorganic color pigments (CICPs) provide enhanced performance in these key areas.

CICPs are very stable pigments, and for all practical purposes are chemically inert. They can withstand the most chemically aggressive environments and still retain their color. They will not fade in the presence of ozone, acid rain, SOx, NOx or other air pollutants common in industrialized areas. They will even remain colorfast in the presence of strong acids, bases, oxidizing or reducing agents. They are non-migratory, and will not dissolve or bleed in contact with solvents.

In addition to excellent chemical stability, CICPs are also the most heat stable type of pigments known. They are made at very high temperatures in a process called calcination. Metal oxides or oxide precursors are blended together and then strongly heated, generally at temperatures over 1,600°F. At the calcining temperature the solids themselves become reactive. Metal and oxygen ions in the solids rearrange to a new, more stable structure, forming the CICPs.

The inherent heat stability of CICPs makes them ideal for high-heat coatings, such as muffler and stove coatings, fireplace paint, and high-heat powder coatings. Porcelain enamel and decorative ceramic coatings almost exclusively use CICPs for color.

In outdoor coatings, UV protection is crucial. CICPs offer superior lightfastness when used in exterior coatings. In addition to the superior chemical stability, they are impervious to all forms of UV radiation. The pigments themselves are completely stable, and do not discolor upon exposure. CICPs absorb incident UV photons and convert their energy to a more benign form, similar to the way organic light stabilizers operate. Many CICPs absorb strongly in the UV region, which makes them very good UV blockers.

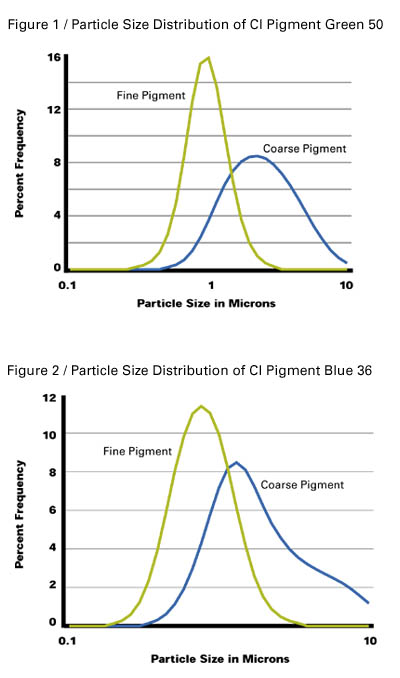

CICPs are excellent UV opacifiers and can effectively prevent UV radiation from penetrating much of the coating by light scattering. Micronized CICPs are very good at scattering UV and visible light away from a coating’s surface. Because of their small particle size and high index of refraction, CICPs will effectively backscatter a significant amount of UV light away from a coating’s surface. Both absorption and scattering of UV light by CICPs acts to keep this dangerous radiation from entering and degrading a coating’s resin matrix.

Courtesy of The Shepherd Color Co.

Courtesy of The Shepherd Color Co. Courtesy of The Shepherd Color Co.

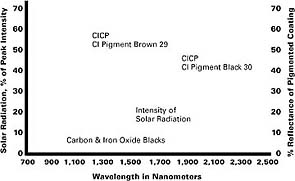

Courtesy of The Shepherd Color Co.Another area where CICPs aid in exterior coatings is in the reflection of IR or heat radiation. For roof and building coatings, CICPs are routinely used because of their excellent weatherability. Certain grades also have the ability to maximize reflectivity in the near infrared region. These IR-reflective CICPs are finding increased use as formulators attempt to produce dark coatings and minimize heat buildup in the underlying structure.

Courtesy of The Shepherd Color Co.

Courtesy of The Shepherd Color Co.Certain CICPs have the ability to absorb strongly in the visible but much less in the near IR. Reflective CICPs such as nickel manganese ferrite blacks (Pigment Black 30) and iron chromite brown-blacks (CI Pigment Green 17, CI Pigment Browns 29 and 35) are increasingly used to provide dark colors with reduced heat buildup.

ASTM Method E 903-96 was designed for estimating the solar reflection from a coating. When IR-reflective CICPs are compared by this method to the more commonly used carbon, iron oxide, and copper chromite blacks, they show a 5–35% increase in reflected IR light. More reflection means less infrared absorption, making a cooler coating. Many of the newer IR-reflective pigments are also good UV and visual opacifiers. The newest grades also have increased tinting strength to provide more value. Their only downside might be the fact that they typically have a less jet-black color than the other pigments.

When formulating an effective coating for exterior or high-heat applications, CICPs should be the colorants of choice. Their unsurpassed chemical and heat stability, good hiding power, UV opacity, and IR reflective properties make them ideal for these demanding applications.

For more information on pigments, e-mail Jwhite@shepherdcolor. com; fax 513/874.0714.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!