Heat-Resistant Inorganic Pigments

Standard yellow iron oxides are the ideal inorganic pigments to develop a wide range of color shades due to the advantages in performance and cost provided by their high hiding power and opacity, excellent weather, light and chemical fastness, and reduced price. But their use in high-temperature-cured coatings such as coil, powder or stoving paints is limited. Why?

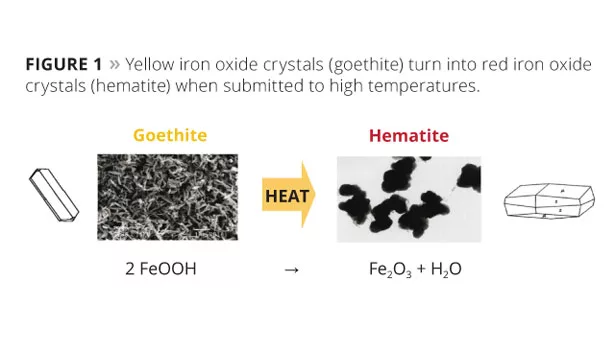

When yellow iron oxides are submitted to high temperatures, their goethite structure (FeOOH) dehydrates and partially turns into hematite (Fe2O3), which is the crystal structure of red iron oxide. This is why the standard yellow iron oxide that exists before curing becomes darker and browner (Figure 1). This change can take place from temperatures close to 160 ºC, depending on the curing time, the binder system and the coating formulation itself.

Heat-Resistant Inorganic Pigments

The intrinsic poor heat fastness of standard yellow iron oxides can be overcome by including our Nubifer K Series zinc ferrites and Nubifer Y-7050 heat-resistant yellow iron oxide inorganic pigments in the formulation.

Zinc Ferrites, Nubifer K Series

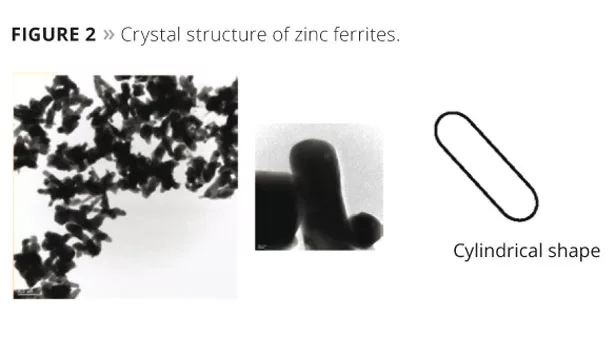

Zinc ferrites are complex inorganic pigments with a ZnFe2O4 spinel crystal structure (Figure 2). Like the yellow iron oxides, they exhibit excellent light, weather and chemical fastness, as well as high hiding power and opacity, but they also withstand high temperatures. Nevertheless, they cannot be used as a direct replacement for yellow iron oxides because their color is significantly different, giving a darker tan shade (Figure 3).

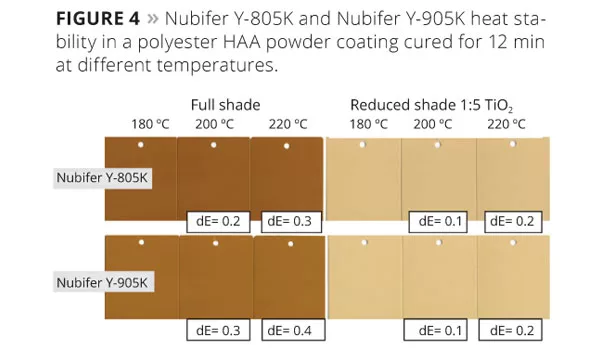

Two zinc ferrites within our product range are especially worth mentioning: Nubifer Y-905K and Nubifer Y-805K. The latter is darker and redder than the first one and is also reported to be the most heat-stable zinc ferrite in the market. It withstands 300 ºC for 5 min in polypropylene, while Nubifer Y-905K reaches 260 ºC under the same conditions. However, the typical curing parameters of coil, powder and stoving coatings make Nubifer Y-905K suitable enough for these applications (Figure 4).

Nubifer Y-7050

Our intensive R&D work has led to the development of a completely inorganic encapsulation of our standard yellow iron oxide that prevents it from changing color when exposed to high temperatures. Being completely inorganic, this encapsulation does not contain any silane or other organic compounds, so it is compatible with all kinds of binders.

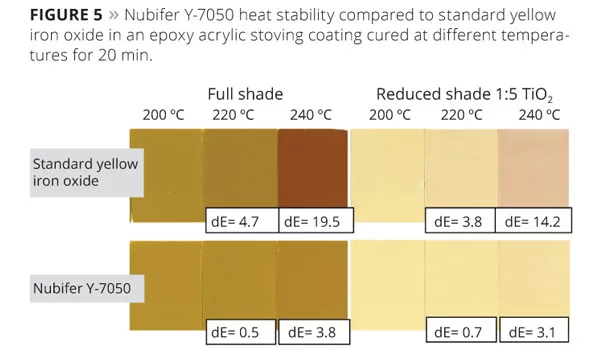

Consider an epoxy acrylic stoving coating as an example; a standard yellow iron oxide already shows a change in color when cured at 220 ºC for 20 min, while Nubifer Y-7050 is practically unaffected. At higher than usual curing temperatures (240 ºC), the difference is even bigger, as the standard yellow iron oxide becomes completely brown, and Nubifer Y-7050 keeps its color shade quite stable (Figure 5).

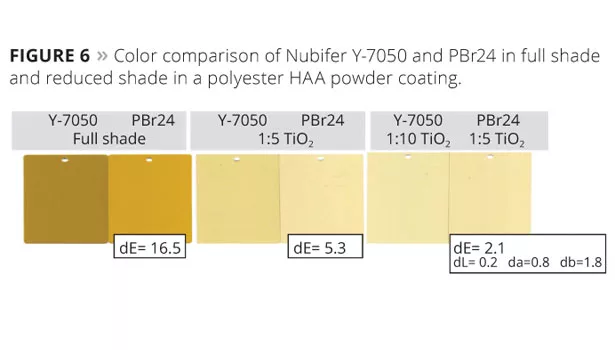

Replacing Pigment Brown 24

Titanate chrome brown 24 (PBr 24) is a yellow, light-brown complex inorganic pigment widely used to develop beige/light-yellow color shades in applications where high temperatures are applied, due to its outstanding heat resistance. Furthermore, it also features excellent chemical, weather and light fastness, and high hiding power. PBr 24 color is different than Nubifer Y-7050 if applied in full shade or in reduced shade at the same dosage. If half of the amount of Nubifer Y-7050 is used, a very similar beige color shade is obtained at a much lower cost, as PBr 24 is much more expensive than Nubifer Y-7050, and 50% more is needed to achieve the same color (Figure 6).

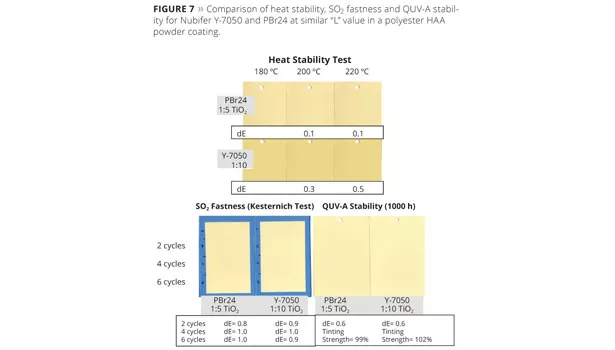

Replacing PBr 24 with Nubifer Y-7050 to develop these beige colors does not affect heat fastness, chemical resistance or light stability, as shown by the results of the heat stability, Kesternich (SO2 fastness) and QUV-A tests in a polyester HAA powder coating (Figure 7).

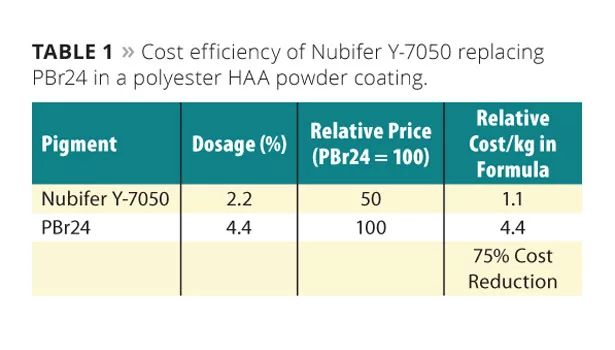

From these results we can conclude that Nubifer Y-7050 shows in reduced shade a better performance/cost ratio than PBr 24. If we consider that the price of PBr 24 is double that of Nubifer Y-7050, the coloration with the latter can be four times cheaper, maintaining the same chemical and physical properties of the coating (Table 1).

Replacing Red Organic Pigments

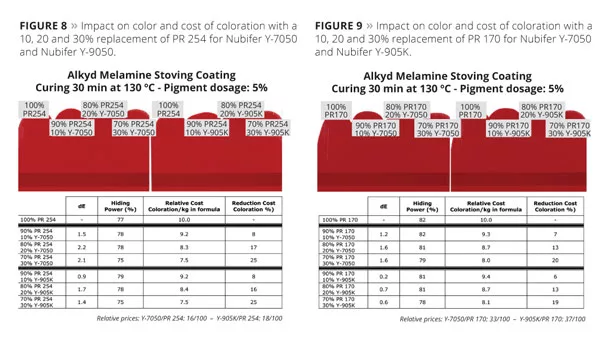

Red organic pigments used in powder, coil or stoving coatings can be partially replaced with Nubifer Y-7050 and Nubifer Y-905K without significantly affecting the color shade or hiding power of the coating. A reduction in the coloration cost, as shown in Figures 8 and 9, is an added advantage.

As shown in the figures, both Nubifer Y-7050 and Nubifer Y-905K are good candidates to replace up to 30% of PR 254 or PR 170 without producing a big change in color shade or hiding power, and provide considerable reduction of cost of coloration: around 25% for PR 254 and 19-20% for PR 170. Nubifer Y-905K affects color the least, especially in the case of PR 170, where a replacement of 20-30% only leads to dE 0.6-0.7.

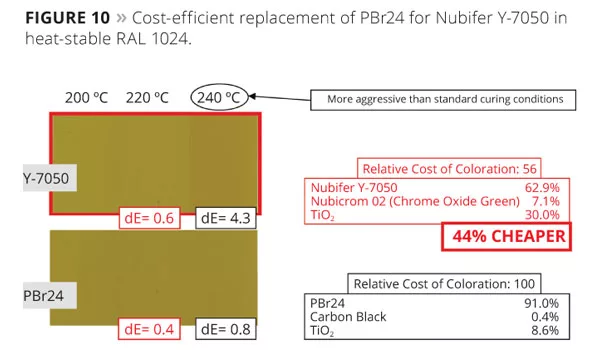

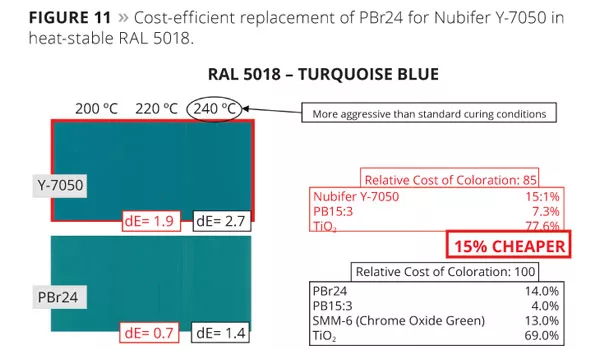

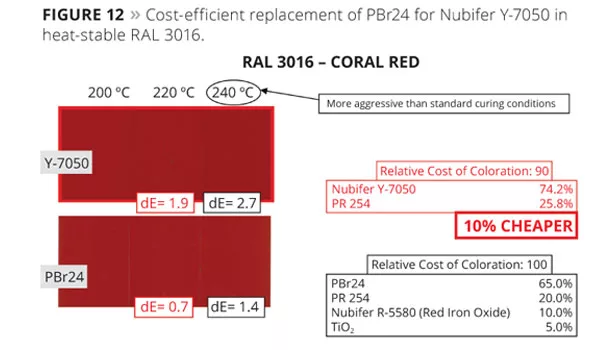

Formulating High-Performance Coatings with Nubifer Y-7050

As already mentioned, the use of standard yellow iron oxides to develop different color shades is limited in high-temperature-cured coatings because the color changes under the needed cure conditions. The way to overcome this limitation is to use high-performance inorganic or organic pigments, but this means a high increase in the cost of the coating. Now you have the choice of developing these kinds of colors with Nubifer Y-7050, obtaining a high-temperature-stable coating with lower price. Some heat-stable RAL colors are presented in Figures 10-12.

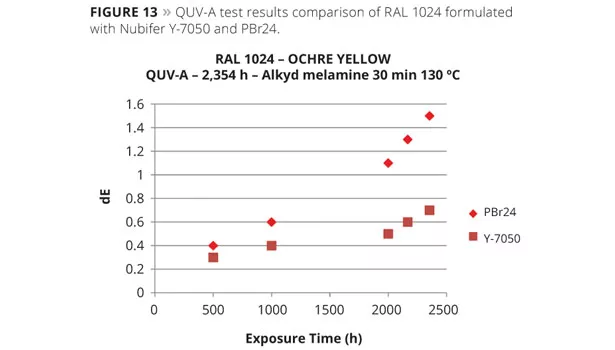

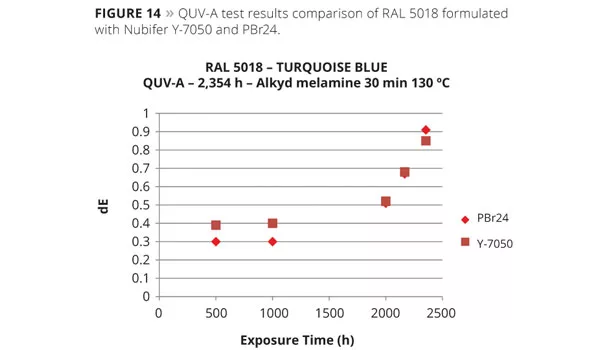

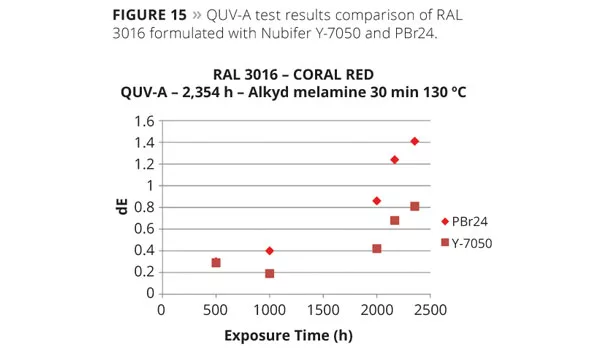

QUV-A test was carried out to confirm that Nubifer Y-7050 does not affect the weather fastness of these RAL colors when it replaces PBr 24. Twelve-hour cycles consisting of 4 h of condensation at 50+ 3 ºC followed by 8 h of UV radiation at 60 + 3 ºC were run for 2,354 h. As shown in Figures 13-15, formulations containing Nubifer Y-7050 show very similar or even better QUV-A stability at the end of the test than those containing PBr24. The binder system used for this test was an alkyd melamine cured for 30 min at 130 ºC.

Summary

Standard yellow iron oxides are the ideal inorganic pigments to develop a wide range of color shades due to the advantages in performance and cost provided by their high hiding power and opacity, excellent weather, light and chemical fastness, and reduced price. Nevertheless, their use is limited in powder, coil or high-temperature stoving coatings because under the curing conditions required in these cases their shade turns darker and browner. The solution is to use heat-stable inorganic (such as PBr 24) or organic pigments, but this makes the formulation costlier. Lower-cost, similar performance options are now available:

- Nubifer Y-7050: Nubiola heat-resistant yellow iron oxide with a completely inorganic encapsulation that makes it stable up to 240 ºC.

- Nubifer K Series: Nubiola zinc ferrites and specifically Nubifer Y-905K, which shows almost negligible color change in different high-temperature-cured paints.

By including these products in your formulations you can formulate cost-efficient, high-performance coil, powder and stoving coatings in all kinds of color shades.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!