A Novel Concept for Improving Scratch and Abrasion Resistance for Automotive Coatings

Overview of Nanoparticles

The word nano comes from the Greek word for "dwarf". One nanometer is 10-9 meter. If a size comparison were made between 1 nanometer and 1 meter, it would be like comparing the size of a U.S. dime at 1.25 centimeter to the diameter of the earth at 12,756 kilometers. Properties such as conductivity, fluorescence, transparency, color, stiffness, ductility and reactivity are affected by the size of the nano particle. A coating made with 25-nanometer size particles will have greater transparency than those with 80 nanometers when used at equal weight levels.One of the most important properties desired by the automotive industry, as mentioned previously, is improved scratch resistance. After 500 cycles of a dry abrasion test, a waterborne UV coating showed marked improvement with 2% nano alumina. Several other tests are used to measure scratch, and these include steel wool # 00 and 0000, a hammer with Scotch-Brite™ and, most importantly for automotive, is the Atlas Crockmeter. Methods for quantifying scratch resistance include a gloss decrease, haze increase or simply a visual examination of the coating.

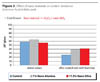

Using the dry abrasion modified ASTM D 2486 test, the 1% alumina maintains excellent gloss after 500 cycles compared to a sample without alumina.

A comparison of UV-coated wood panels, both with and without nano alumina, showed a significant loss of gloss for the untreated panel compared to the one with the nanosilica. The importance of the smallest particle size for the least amount of haze is seen from the graph in Figure 1 where the 20-nanometer size does not contribute nearly the amount of haze as the 10- or 50-micron size particle.

Transparency Drivers

Besides the particle size, the film thickness is also important regarding haze. With lower film thicknesses, especially when alumina particles are used, less haze is visible. A 2% alumina level gives a haze value of 0.5% at 10 microns and goes to a value of 1.55 when the film thickness is 25 microns. The refractive index of the coating is also influential in determining the amount of haze. A melamine formaldehyde coating containing alumina has less haze than a UV coating at equivalent levels.Various types of products are available for alumina with different particle sizes, surface modifications and solvent types. For silica, which will be the main focus for OEM and refinish clearcoats, there is one main product and it is designated as "NANOBYK" in this article.

Particle Characteristics

A detailed look at the morphology and density, and most importantly, the refractive index are highlighted in Table 1. It is mainly the refractive index difference between alumina and silica and that of the resins used that prevents the development of haze-free nano additives for clearcoat systems with alumina. The refractive index of silica is around 1.55 and approximates that of most coating resin systems. Even though the hardness of the silica particle is less than alumina, it will be shown that it can still provide significant scratch protection without causing an increase in haze.Atomic force microscopy pictures exhibit the topographical differences before and after 1000 dry abrasion scrubs using a modified dry abrasion ASTM 2486 test method. Comparisons are made with 20-nanometer alumina and 40-nanometer with both having 0.2% PDMS.

The use of 17.5 % nanosilica, a more conventional product compared to 1% of a treated nanoalumina particle, indicates equal performance after the Hammer Scotch Brite test (Figure 2). A similar result is obtained in a solvent-free UV coating with 2% alumina to 18% silica. Upon microscopic examination after 1000 cycles of dry abrasion, the significant improvement with the modified alumina additive is apparent. The challenge becomes how to use silica at a much lower level and yet obtain excellent scratch resistance and have no effect on haze. This can be done by index matching and, as mentioned previously, achieve a refractive index of 1.55, which is close to that of resins. Other critical factors are nano concentration, film thickness and particle size.

-

1. The transfer of the nanosilica from the water phase into the solvent phase. This is accomplished with a special solvent.

2. The modification of the nano surface with a silicone to allow uniform distribution throughout the film.

3. The deflocculation and stabilization of the particles to prevent reagglomeration.

Figure 3 shows the importance of covalently bonding the siloxane to the nanoparticle. Just adding the siloxane to the silica does not offer the same level of scratch improvement as when the PDMS is bonded directly to the silica.

The photograph in Figure 4 shows how the stabilization of the nanoparticle is critical for deflocculation and distribution. The wetting and dispersing agent enhances the distribution throughout the film.

Particle Distribution

The particle size distribution chart in Figure 5 indicates that 60% of the nanoparticles are in the 20-30 nano range, and 32% are in the 30-40 nano range in the actual paint film. Therefore, over 90% are within a very narrow range of particle distribution.

NANOBYK Proposed Theory

The theory behind how the nanoparticles function at this point is only a theory. The silica or alumina particle provides the mechanical properties of improved scratch resistance. As mentioned previously, the refractive index of the silica is nearly approaching that of resin systems. Around this particle core is built a shell, which is comprised of a wetting agent and a siloxane. This shell provides the compatibility and stability to the system through the resin matrix. A larger interface region has been created, and therefore a lower level of particles is needed to achieve the desired properties. Examination of a clearcoat film as seen in Figure 6 indicates uniform distribution throughout the film.The NANOBYK treated and stabilized particles do have an influence on surface tension due to the modification with siloxane. Note that the additive levels for NANOBYK described herein are delivery form on solid resin in the system. In an acrylic/isocyanate system, the control has initial surface tension of 27.3 dynes/cm. The addition of slightly over 1%, as delivered, NANOBYK lowers the surface tension to 25.8 dynes/cm. Increasing the level to 2.0% results in a surface tension of 25.2 dynes/cm. Increasing the level to 3% and 4% does not significantly lower surface tension, but additional improvements in scratch can be realized. In an acrylic/melamine system, a level of slightly over 2.0%, as delivered, lowers the surface tension from 29.1 to 27.1 dynes/cm. It is therefore not necessary to add any additional surface flow-control additives to lower surface tension. Recommendations are in fact to leave out all additives before using the NANOBYK and to make final adjustments as required after testing.

Scratch Resistance

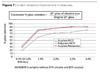

Figure 7 compares different levels of NANOBYK after scratch using the Crockmeter with 9-micron paper. The percent gloss retention is calculated by dividing the gloss of the abraded area by the original gloss. An acrylic/melamine or acrylic/isocyanate system shows 80% retention even at 1.0%, as delivered, NANOBYK compared to a control, which only has 30% retention. Increasing the NANOBYK to over 3.0% improves the gloss retention to over 90%. There are no additional additives to improve scratch resistance in these NANOBYK trials.If we take a coating and run the Crockmeter test for 10 cycles and then polish off 10 microns from the surface and then run the Crockmeter test again, the percent gloss retention is still 87%. This is further evidence that the nano particles are evenly distributed throughout the film and still provide scratch resistance and a permanent effect.

A key factor, especially for OEM and refinish clearcoats, is that an additive should not have any negative effects on gloss, haze, flow and leveling, pot life for 2K-urethane systems, adhesion, recoatability, water resistance and weatherability.

In three different systems there was no influence on the 20-degree gloss, and the haze was actually slightly less than a more conventional additive package for clearcoats. The long and short wave appearance was also slightly improved with the NANOBYK product even up to 4.0%. In a 2K-urethane system, using a conventional aliphatic isocyanate, the pot life was not affected with the NANOBYK.

QUV Results

The QUV testing was done for 500 and 1000 hours; the panels were then subjected to the Crockmeter testing. Results shown in Table 2 indicate that a level of slightly over 4.0% NANOBYK becomes more significant after 500 hours and 1000 hours QUV exposure for maintaining improved scratch resistance. The QUV chart in Table 3 of the unabraded samples indicates an actual improvement over the control in maintaining gloss after exposure. The silica may be helping to prevent UV degradation.There has not been any interference with intercoat adhesion or flexibility when the NANOBYK is used at a maximum level of 4% on resin solids. Another advantage of the NANOBYK is the ease of incorporation into the system. Since it is liquid, the NANOBYK can be added with minimal agitation, while mixing, and should be added toward the end of the process. The use of NANOBYK can preclude the use of other additives for substrate wetting, anti-cratering and surface slip. When formulating, the recommendation is initially to leave out all flow and surface additive silicones and acrylates before adding the NANOBYK. If fine-tuning is necessary, then adjustments can be made with acrylates or silicones with minor influences on surface tension.

Summary

NANOBYK is a liquid nanosilica product that offers improved long-term scratch improvement with a much lower level of silica than conventional nano silicas. There is no negative influence on other film properties such as gloss and haze, and since the additive is equally distributed throughout the film, performance is maintained even after exposure and physical testing.This paper was presented at the International Coatings for Plastics Symposium, June 2006, Troy, MI.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!