EVOPeration

Batch History Review

Mr. Engineer enters Dr. Scientist’s offices and says, “I understand you wanted to talk to me about the batch records for POLYGLOP 123?”“Yes. I noticed that you are not running at the same conditions that were defined in the statistically designed laboratory process study and wondered if you could tell me what has happened?” said Dr. Scientist.

Mr. Engineer replied, “When you used statistically designed experimentation to define the response surface for the reaction yield, you found that the optimum conditions to maximize the yield occurred at 142 °C and 6 hours.” (Figure 1)

Mr. Engineer continued, ”When we transferred these conditions to the plant, we did not achieve the 97% yield that you reported, but instead the first batch only achieved about 87%. This is not unusual when lab data is used in production, usually due to different equipment configuration, for example agitation. Fortunately we know of a technique to optimize manufacturing procedures, using experimental design techniques that will not disrupt production work-flow. The technique is called EVOP.”

Dr. Scientist replied, “I’ve heard of EVOP. I recall that this is an acronym for Evolutionary Operation. How does it work?”

“You’re correct. EVOP was first discussed by Box in 1957 and was then discussed in greater detail in the book Evolutionary Operation, written by Box and Draper in 1969.2 In operation, minor variations for selected variables are made to each batch. These variations are so small that the yield differences remain within the normal yield variations of production. Only by repeating these production experiments many times can trends in improvements be seen. Once a trend is identified, a small change in operating conditions is made to achieve the improvement. Then the process is repeated until no changes are indicated. Typically, only two or three of the most important variables are evaluated. Once these variables are under control, other minor variables can be evaluated for continuous improvement. Of course, the original variables continue to be monitored by EVOP in case of changes in raw materials or other production variables.”

“That’s very interesting. What are the current operating conditions and yields?” asked Dr. Scientist. “Currently, the plant is operating at 145 °C for 6 hours and 10 minutes to give an average yield of 96.6% with a standard deviation of 1.6%,” answered Mr. Engineer. “Such a minor change resulted in regaining the 97% change in yield,” replied Dr. Scientist thoughtfully. “Please tell me more about the EVOP procedure.”

EVOP Applied to the POLYGLOP 123 Process

Mr. Engineer began, “We took the laboratory results shown in Figure 1 as the starting point and selected an experimental design with four corner points and a center point, as shown in Figure 2. Code 0, the center point, was assigned to the suggested operating conditions, and Codes 1 to 4 were assigned to the corner points.”In his book, Evolutionary Operation, Box utilized a five experiment factorial design. When each of the experiments were run once, he called this a cycle; five cycles he called a phase. So, each phase represents 25 experiments. After five cycles, that is one phase, are run, the data are analyzed to determine whether the center point of the design should be changed to new temperature and time coordinates. Whether the change in coordinates is made or not, the procedure is repeated with five new cycles and subsequent data analysis. Normally, all five experiments are run before any are repeated. The order could be uniform: 1,2,3,4,0; 1,2,3,4,0; etc.; or could be random: 2,3,0,1,4; 1,3,4,0,2; etc. Of course, random is better.

“The reason five cycles are run is that for any one cycle, the noise in the operation will drown out the effect of the variation imposed by the small changes in the temperature and the time. By running several cycles, the signal-to-noise ratio can be increased, so that the real effect can be seen. This has to do with standard error of measurements3 (Applied statistics simplified: or,‘t time,’ APCJ, September 11, 1995).

“In the case of POLYGLOP 123, the first cycle for the design centered at 142 °C and 6 hours gave the following results: Experiment 0 gave a yield of 89%; Experiment 1 gave 87; Experiment 2 gave 89; Experiment 3 gave 88; and Experiment 4 gave 90. There is no clear pattern evident.

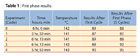

However, after five cycles, the completed phase, the situation clarified itself because the replication decreased the noise. The results are given in Table 1 and plotted in Figure 3.”

“From the table or the figure it is obvious that the next set of experiments should be centered at 143 °C and 6 hours and 10 minutes, the site of the maximum yield for the first phase of EVOP. Another phase was run at these new conditions and the evaluation of the data was repeated. A total of 4 phases were run to get to the current operating conditions. The centers, Experiment 0’s, of each phase are shown in Figure4.”

“When we ran the five cycles of five experiments of the fourth phase, we found that Experiment 0, the center point, gave a yield of 97%; Experiment 1 gave 94; Experiment 2 gave 95; Experiment 3 gave 95; and Experiment 4 gave 96. Since the completion of that phase, the standard operating conditions have been set at 145 °C and 6 hours and 10 minutes, and the average yield has been 96.6%,” finished Mr. Engineer.

Continuous Improvement

Dr. Scientist wondered, “Does this mean that you no longer need to use the EVOP procedure in production?” Mr. Engineer answered, “We are continuing to run EVOP phases on time and temperature. So far there has been no need to change the coordinates for the center of the design. In the future, however, something in the process might change: the raw materials might change; a thermocouple or clock might be replaced; or the process procedure or equipment might be modified. So we continue to use EVOP to study optimum temperature and time conditions.“Also, since it appears that we are at an optimum for time and temperature, we are now considering if there are other variables that could be evaluated by EVOP, such as reactant ratios or agitation rate. “By continuing to run EVOP we can be assured that we will always have our process centered at the process conditions to achieve an optimum yield.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!