Silicones in Coatings

Architecture is the most vulnerable of all human art forms, and silicone systems are increasingly the dominant material for sensitive restoration of heritage landmarks. Thanks to their particular chemistry, versatility and the inventive dynamism of producers, silicones have become one of the primary materials used in systems to protect buildings against the weather. They are also particularly appropriate in resistance to airborne pollution. These qualities are equally important for architectural creativity in new construction: new silicone sealant technologies are at work in ‘intelligent’ glass-based facades to promote aesthetic and sustainable development criteria.

Silicone properties are well suited to surface coating and surface treatment applications. As main components, silicones offer resistance to weathering in paints for exterior surfaces such as bridges and metal cladding on buildings. They provide water repellency to masonry surfaces such as stone and brick. Silicone resins also have greater resistance to high temperatures than organic resins.

Silicone polymers have unique properties that bring benefits to a wide variety of coating types, whether as additives or binders. They are used in solvent and waterborne systems, in radiation-cured varnishes and powder coatings. They are used in varnishes for furniture, paints for houses, coatings for cars and inks for newspapers. Application examples cover a range in which almost the entire coatings consist of silicone materials to one where the silicone is present at less than half a percent.

In heritage preservation, silicones protect the structural integrity of a building so it can stand the test of time. By adding a silicone-based treatment product to the façade, historical buildings are protected without compromising their appearance. Silicone sealants, adhesives, structural glazes and coatings, because of their high resistance to heat, wind, moisture and chemicals, slow down erosion of buildings and building materials – even in the most extreme climates.

Creative Architecture

Silicones have many uses in construction, from engineering sealants and adhesives to masonry water repellents, industrial coatings and maintenance, and also for conservation and restoration.Some examples of renowned buildings where silicones have been used are skyscrapers and innovative building developments from the Baiyoke II Tower, Thailand’s tallest, to Kuala Lumpur Airport, Malaysia. Famous high-rise landmarks in Bahrain, Dubai, Hong Kong, Japan and the United States among others all use silicone sealants for protection.

Silicones have been used in construction since 1938. The UN Plaza Apartments in New York have been standing since 1965, demonstrating the durability of the silicone sealants used. Product innovation today allows for flexible design combined with protection and durability in the construction. Modern silicone products enhance the performance and security of buildings.

In a world where sustainability and energy efficiency are increasingly important due to environmental concerns as well as rising energy costs, silicones enhance energy efficiency. An efficient insulating façade with silicone-enhanced glass panels minimizes thermal loss, reducing the need for both heating and cooling a building and therefore cutting energy consumption and cost.

Conservation and Restoration

As well as bringing significant benefits to new constructions through adhesives, sealants and structural glazing, silicones are of major importance to renovation and restoration work.Many of the world’s culturally significant buildings were built with natural materials – porous sandstone and limestone – that are susceptible to weathering. Humidity and wetness are the major reasons for various kinds of damage and unsightly appearance in buildings. The porous structure of different mineral building materials leads to capillary absorption and a high sensitivity towards water absorption. The destructive effects of freeze and thaw changes, structural erosion, and microorganisms that thrive in humid environments are common problems.

Also in concrete buildings, erosion of reinforcing steels can be attributed to the corrosive effects of absorbed water, and require expensive renovation. Efflorescence, lime washout and the growth of mosses, fungi and algae all occur on wet surfaces. Eventually the temperature insulation of wet masonry is adversely affected.

Silicone sealants and adhesives are used to add a protective layer without compromising the appearance of the building. They restore the material to its original strength by penetrating the stone through to the undamaged core and restoring the natural mineral. This treatment does not compromise the physical characteristics of the stone or the structure.

While significantly reducing water absorption, treatment with a silicone-based impregnating emulsion does not affect the vapour permeability or breathability, nor the thermic or hydric behaviour of the stone. This water permeation of water vapour from the substrate to the outer surface is essential for a healthy indoor environment as it prevents build-up of condensation inside the building, which can provide perfect conditions for algae and fungi growth.

Impregnating agents are a combination of siloxane and silanes as a water-based emulsion or solvent-based solutions, which do not change the optical appearance of natural substrates as they do not contain pigment systems.

Figure 1 shows comparisons with silicone-treated limestone and non-treated material exposed for a three-month period under a tree. The limestone treated with the silicone-based product remains unaffected by the conditions while untreated stone has attracted growth of microorganisms.

Figure 1 also shows untreated clay brick exposed for a nine-month period in dry conditions. Efflorescence is present on the untreated sample whereas the silicone-treated brickwork remains untouched.

Tests at the Polymerinstitut in Floersheim, Germany, showed that the reference sample of concrete was badly affected by freeze-thaw cycles and the silicone-treated sample was unaffected.

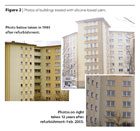

Another example of silicone technology is a test on a building treated in 1993 with silicone-based decorative paint (Figure 2). Twelve years after the refurbishment, the stonework showed no sign of damage or stains.

Statues and other stonework can be given long-term protection by silicone coatings. In Vienna, for example, extensive restoration work has been carried out using silicones with the full support of the city authorities.

An optimal masonry coating system should be:

- water-repellent;

- microporous;

- highly permeable to water vapour;

- highly permeable to CO2;

- resistant to aggressive airborne pollutants;

- not a breeding ground for fungi, algae and mosses;

- solvent-free or low solvent;

- water-thinnable, environmentally compatible; and

- non-thermoplastic.

The Centre Européen des Silicones (CES) is a nonprofit-making trade organization representing all major producers of silicones in Europe. The organization, which is based in Brussels, Belgium, is a sector group of European Chemical Industry Council, CEFIC. For more information, there are two CES websites - www.silicones-europe.com, which give general information on the industry, applications and benefits of silicones, and www.silicones-science.com, which is a scientific site providing information on silicone chemistry and performance properties. CES is a partner organization of SEHSC, the Silicones Environmental Health and Safety Council in North America.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!