Green Solutions for Substrate Wetting and Defoaming

In the modern world, companies simply cannot afford to ignore environmental issues. This sustainability trend is driven by society’s changing values, with consumers demanding that industry act more responsibly, and governments around the world introducing increasingly strict legislation to ensure it does so.

In the modern world, companies simply cannot afford to ignore environmental issues. This sustainability trend is driven by society’s changing values, with consumers demanding that industry act more responsibly, and governments around the world introducing increasingly strict legislation to ensure it does so. International coatings manufacturers are among the companies that have to comply with stricter environmental regulations, while at the same time improving product performance and meeting the requirements of consumers.

VOC emissions are one of the most important formulation parameters in the coatings industry. VOCs participate in atmospheric photochemical processes, and are believed to contribute to the formation of ground-level ozone. For these reasons, regulatory limits have been set in many parts of the world to limit their content in paints and related products.1 Also, customers are increasingly looking for additives that have low or zero VOC content, but they are not prepared to compromise on performance, and demand the usual application level.

Waterborne coatings are generally known to reduce the levels of VOCs, but to achieve satisfactory performance, formulators have to use an array of additives such as wetting agents, coalescents, rheology modifiers and defoamers.

According to research conducted by Frost & Sullivan, the total value of the U.S. market for surfactant paint additives was approximately $380 million in 2004, with 30 percent of this accounted for by surface and flow modifiers, and 70 percent by wetting and dispersion agents.3 Cognis’ new Starfactant technology further enhances the functionality of FoamStar by combining defoaming and wetting functions in a single chemical structure. The hyper-branched structure of these non-ionic surfactants was modified to give them additional wetting properties. The chemistry is based on Cognis’ main raw materials like fatty alcohol ethoxylates.

The following examples demonstrate the alternatives that now exist for solvents that come with additives in formulations without compromising on performance. These examples show that as well as the environmental benefits, these formulations also offer functional benefits over conventional technologies due to improved gloss and clarity, when comparing the wetting and defoaming properties. The examples also demonstrate how they eliminate the need for additional solvent washes, which increase overall VOC emissions.

White Acrylic Formulations

White Acrylic Formulations

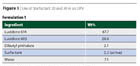

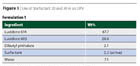

The first example is the use of Starfactant 20 and 30 in an OPV based on two Lucidene® emulsions (Formulation 1), which is shown in Figure 1.

The first benefit is that compared to the original formulation, which uses dioctyl sulfosuccinate as a surfactant, no additional defoamer is needed. Even if the amount of VOC coming from organic solvents in sulfosuccinate-based wetting agents and defoamer is relatively low, there is no VOC from the Starfactants.

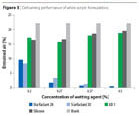

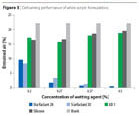

None of the defects shown in Figure 2 were seen in the acrylic emulsion formulations containing Starfactant 20 or 30, which were spray-applied to PVC. The other formulations tested use solventborne silicone surfactants, or so called “Gemini surfactants”, and show significant defects in the coating.

To improve water resistance or blocking properties, about three percent of wax-based products can be added to this formulation.

Figure 3 shows the effect on foam content when increasing the amount of the wetting agent. As is typical of most wetting agents, in the competitor systems the amount of foam increases in proportion to the level of wetting agent. But with Starfactant products, the opposite is true. As the wetting agent content increases, the amount of foam or entrained air is reduced. To demonstrate further evidence of the defoaming benefits of Starfactant, a white acrylic formulation based on Joncryl® 1532 resin was produced without any additional defoamers. Using the competitor technologies, it simply would not be possible to create a viable defoamer-free spray-on acrylic.

Black PUD Formulations

Black PUD Formulations

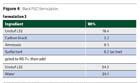

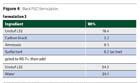

In a second formulation (Figure 4), the wetting and entrained air results are shown for a black PUD formulation based on Reichhold’s Urotuf L52 dispersion, again without an additional defoamer.

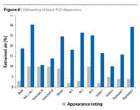

Figure 5 shows that Starfactant 20 and 30 provide sufficient substrate wetting to coat the oil-contaminated steel plates. The main benefit in this case is that excellent wetting and coating is achieved without the need for further cleaning of the oily steel panels. To get comparable results with the other formulations tested, the oil must first be removed, using either a solvent or a surfactant pre-wash. A solvent wash would increase the total VOC emissions of the process as a whole, while a surfactant wash would produce further oil-containing waste. The use of Starfactant chemistry eliminates both these potential problems.

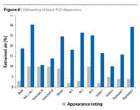

Figure 6 shows the entrained air results for the black PUD formulation. As defoamers were not used in the formulations tested, only the Starfactant products delivered the desired combination of low foaming and acceptable appearance. In this test, substrate wetting was rated on a scale from zero to 10. Ten represents no defects in the coating at all – the more effects such as mottling, pinholes, craters and fisheyes are observed, the lower the score. As the graph shows, Starfactant technology provides by far the best combination of wetting, low foaming and appearance.

In the modern world, companies simply cannot afford to ignore environmental issues. This sustainability trend is driven by society’s changing values, with consumers demanding that industry act more responsibly, and governments around the world introducing increasingly strict legislation to ensure it does so. International coatings manufacturers are among the companies that have to comply with stricter environmental regulations, while at the same time improving product performance and meeting the requirements of consumers.

VOC emissions are one of the most important formulation parameters in the coatings industry. VOCs participate in atmospheric photochemical processes, and are believed to contribute to the formation of ground-level ozone. For these reasons, regulatory limits have been set in many parts of the world to limit their content in paints and related products.1 Also, customers are increasingly looking for additives that have low or zero VOC content, but they are not prepared to compromise on performance, and demand the usual application level.

Waterborne coatings are generally known to reduce the levels of VOCs, but to achieve satisfactory performance, formulators have to use an array of additives such as wetting agents, coalescents, rheology modifiers and defoamers.

Single Chemical Structure Combines Defoaming and Wetting

In response to this demand, Cognis has developed its FoamStar® and Starfactant® product lines especially for use in low-VOC waterborne formulations. While conventional defoamers use ingredients such as mineral or white oil, which scavenge surface-active substances and hydrophobic solids to increase drainage, there is now new chemistry capable of delivering effective defoaming at the molecular level. Cognis’ FoamStar was the first molecular defoamer of this kind to be launched on the market. Its hyper-branched, star-shaped surface-active ingredients form an antagonistic surfactant mechanism with other surfactants in coatings and other applications. The molecular-based defoamer eliminates foam and enhances coating properties.2According to research conducted by Frost & Sullivan, the total value of the U.S. market for surfactant paint additives was approximately $380 million in 2004, with 30 percent of this accounted for by surface and flow modifiers, and 70 percent by wetting and dispersion agents.3 Cognis’ new Starfactant technology further enhances the functionality of FoamStar by combining defoaming and wetting functions in a single chemical structure. The hyper-branched structure of these non-ionic surfactants was modified to give them additional wetting properties. The chemistry is based on Cognis’ main raw materials like fatty alcohol ethoxylates.

Product Performance

Starfactant 20 and 30 are non-ionic wetting agents that are virtually 100-percent active, designed for use in waterborne coatings for metals, woods and plastics. These liquid products are free of silicones and alkylphenol ethoxylates, and are not formulated with additional solvents. VOC content, as determined in accordance with EPA regulations (Method 24), is less than one percent. In tests carried out for example with SITA Foam Tester, Starfactant 20 and 30 achieved substantially better results than benchmark low-foaming agents.The following examples demonstrate the alternatives that now exist for solvents that come with additives in formulations without compromising on performance. These examples show that as well as the environmental benefits, these formulations also offer functional benefits over conventional technologies due to improved gloss and clarity, when comparing the wetting and defoaming properties. The examples also demonstrate how they eliminate the need for additional solvent washes, which increase overall VOC emissions.

The first example is the use of Starfactant 20 and 30 in an OPV based on two Lucidene® emulsions (Formulation 1), which is shown in Figure 1.

The first benefit is that compared to the original formulation, which uses dioctyl sulfosuccinate as a surfactant, no additional defoamer is needed. Even if the amount of VOC coming from organic solvents in sulfosuccinate-based wetting agents and defoamer is relatively low, there is no VOC from the Starfactants.

None of the defects shown in Figure 2 were seen in the acrylic emulsion formulations containing Starfactant 20 or 30, which were spray-applied to PVC. The other formulations tested use solventborne silicone surfactants, or so called “Gemini surfactants”, and show significant defects in the coating.

To improve water resistance or blocking properties, about three percent of wax-based products can be added to this formulation.

Figure 3 shows the effect on foam content when increasing the amount of the wetting agent. As is typical of most wetting agents, in the competitor systems the amount of foam increases in proportion to the level of wetting agent. But with Starfactant products, the opposite is true. As the wetting agent content increases, the amount of foam or entrained air is reduced. To demonstrate further evidence of the defoaming benefits of Starfactant, a white acrylic formulation based on Joncryl® 1532 resin was produced without any additional defoamers. Using the competitor technologies, it simply would not be possible to create a viable defoamer-free spray-on acrylic.

In a second formulation (Figure 4), the wetting and entrained air results are shown for a black PUD formulation based on Reichhold’s Urotuf L52 dispersion, again without an additional defoamer.

Figure 5 shows that Starfactant 20 and 30 provide sufficient substrate wetting to coat the oil-contaminated steel plates. The main benefit in this case is that excellent wetting and coating is achieved without the need for further cleaning of the oily steel panels. To get comparable results with the other formulations tested, the oil must first be removed, using either a solvent or a surfactant pre-wash. A solvent wash would increase the total VOC emissions of the process as a whole, while a surfactant wash would produce further oil-containing waste. The use of Starfactant chemistry eliminates both these potential problems.

Figure 6 shows the entrained air results for the black PUD formulation. As defoamers were not used in the formulations tested, only the Starfactant products delivered the desired combination of low foaming and acceptable appearance. In this test, substrate wetting was rated on a scale from zero to 10. Ten represents no defects in the coating at all – the more effects such as mottling, pinholes, craters and fisheyes are observed, the lower the score. As the graph shows, Starfactant technology provides by far the best combination of wetting, low foaming and appearance.

Conclusion

End users in the coatings market are increasingly demanding environmentally friendly solutions, but they are not prepared to compromise on performance. To help manufacturers meet these expectations, specialty chemicals suppliers must provide them with high-performance chemistry solutions that are safe, reliable and environmentally sound. One of the major issues facing coatings manufacturers today is the need to develop products that comply with the limit of between zero and 50 grams of VOC per liter. Cognis’ Starfactant is free of silicone, alkyl phenol ethoxylates and solvents, and can help manufacturers improve the performance, product quality and profitability of their products. It offers a balanced blend of performance attributes, combining highly effective defoaming with enhanced wetting and dispersing properties.Sidebar: VOC: Environmental Regulations

The recently approved European deco-paint VOC directive defines VOCs in paint products on the basis of their boiling point: a substance is classed as a VOC if its initial boiling point is below 250 °C.4 The directive requires that VOC content be determined by either the ISO11890-2 or ASTM D 2369 method. The European definition is rather different from that applied in the United States, which is based on determining levels of paint volatiles under specific experimental conditions.5Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!