Designing UV-Curable Materials For High-Temperature Optical Fiber Applications

Coatings for optical fiber have traditionally had stringent requirements regarding resistance to a number of environmental factors including heat, humidity and extremes of temperature. In addition to this, the cure speed demands of the fiber draw process have been amongst the most stringent in the UV/EB-curing industry, often with line speeds exceeding 1500-2000 meters per minute.

Industry standards are in place for accelerated aging performance of fibers in telecommunications cable at 85 °C, 85 °C/85% relative humidity and temperature cycling from –65 to 85 °C. Among the main properties being monitored in these aging tests is how resistant the fiber is to transmission or “attenuation” loss after aging. Stresses in the coating due to thermal transitions, embrittlement or polymer chain scission due to thermo-oxidation and/or volatilization of unbound components can lead to small-radius bends in the fiber or micro-bending, which can result in a less than ideal path for light transmission.

In addition, certain polymeric materials used as protective coatings on the fiber or in the cable can generate hydrogen gas at higher temperatures and, if the hydrogen is allowed to migrate into the glass itself, can create areas that actually absorb the wavelengths of light being transmitted. This process is known as darkening of the fiber. These and other factors make the design of rapidly curing coating materials a challenge for higher temperature applications.

New Optical Fiber Application

A newer application for optical fiber is in the subterranean exploration of oil deposits. These are commonly referred to as “downhole” or “geophysical” applications. Since 1993, optical fiber has been used to sense conditions such as temperature, pressure and chemical environment (pH) in oil wells at distances up to at least 30 kilometers. In the past, performing these measurements with standard electrical sensing technology has proven difficult, due to the need of regenerating the electrical power for these distances. There are an estimated 200 fiber optic P&T (pressure and temperature) gauges and 40 downhole fiber optic flow meters installed as of the early part of 2007.1 Fiber optic sensors have improved the ability to “see” oil deposits from the surface and have enabled more efficient draining of the deposits once found.In a downhole fiber application, the well temperatures can range from near ambient to between 90-250 °C.2 As such, standard acrylate-coated optical fiber will not work for this entire service range, as much of the typical communications-grade fiber is rated at below 100 °C operating temperature. The bare silica glass in downhole optical fibers is typically sealed with a carbon or hermetic coating that is extremely resistant to hydrogen migration. On top of this hermetic coating, different chemistries are used that dramatically influence the final operating temperature of the fiber. Typically, acrylate coatings are used for applications from 85 to 150 °C. From 150 to 200 °C, silicones and fluorinated materials such as PFA (tetrafluoroethylene perfluoroalkylvinylether copolymer) are used, and, for applications demanding 200-300 °C, a polyimide coating is used.3-5

In these sensor applications, as well as in more typical telecommunication environments, the coating will preferably be strippable from the underlying glass in order to splice, or connect, to other optical fibers or directly to instrumentation. The ease with which the stripping can be performed is a key factor in how practical they are to use in the field. Acrylate coatings typically can be stripped by mechanical methods either at ambient temperature or by using a heated tool. One issue with using the more heat-resistant chemistries is the difficulty in removing them from the fiber. For instance, polyimide coatings often require a very strong acid in order to achieve removal. This is time consuming and involves special handling techniques.

Acrylate Coatings

As a class, acrylate coatings tend to outperform other chemistries for cost, ease of processing, cure speed and commercial availability. Silicones and polyimides are typically slower curing, in many cases are solventborne, and often are incompatible with other components in the liquid form.The purpose of this paper is to present some of the work conducted to maximize the operating temperature range of acrylate coatings in these types of applications. As part of this work, six outer or “secondary” coatings for optical fiber were tested for changes in weight loss, color and tensile properties after aging at progressively higher temperatures. Secondly, a number of monomeric and oligomeric components were cured and heat aged to assess resistance to weight loss as baseline information for further coating development.

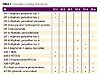

Coatings Evaluated

Table 1 gives a breakdown of the different components present in the six optical fiber coatings tested. Nine different types of urethane acrylate (UA) oligomers, one bisphenol-A epoxy diacrylate oligomer and various acrylate monomers are present in these chemistries. An α-hydroxy ketone photoinitiator and a standard bis-phenolic antioxidant are present in each of these as well. These coatings were cured using a Fusion 600 Watt/inch irradiator with an “H” bulb. The radiant energy density, or UV dose used to cure these coatings, was 1000 mJ/cm2. A 3-mil bird applicator was used to cure films on glass. The coating, glass and applicator were all allowed to equilibrate to 85 °C before curing in order to minimize vitrification effects, as these coatings have glass transition temperatures well above room temperature, typically >75 °C. After curing, the films were removed from glass and allowed to equilibrate in a 23 ± 2 °C/ 50 ± 5% RH environment before subjecting them to aging at 125, 175, and 225 °C heating in forced air ovens.

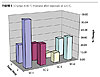

Weight Loss Change

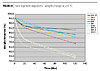

Figure 1 shows the weight loss of these coatings after 24 hours at 125, 175, and 225 °C. Figure 2 shows weight loss after 1, 2 and 24 hours at 225 °C. From this data, it is clear they lose a significant fraction of their weight at 225 °C after only a short period of time. Exposure to this condition can serve as a quick screening process for relative heat resistance, but the data at 125 and 175 °C may provide a better metric as to continuous service temperature.

Color and Tensile Changes

The color and tensile property changes were also evaluated for the SC-1 through SC-6 compositions. These results are shown in Figures 4 and 5. The color change is assessed by measuring the Delta E of the aged films over a standard white background tile. All of the films will approach a similar Delta E value with enough exposure time at 225 °C, but the rate of discoloration is clearly slower for the SC-3 than with the other formulas.

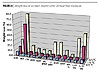

Fast-Cure High-Temperature Changes

Investigations were further made into suitable faster-curing high temperature materials for optical fiber applications. Various monomeric components were cured using a loading of 4% α-hydroxy ketone photoinitiator and 1% bis-phenolic antioxidant. These films were prepared using a 1.5-mil wire-wound rod at 60 °C on glass and 1000 mJ/cm2 using the same curing lamp mentioned previously. The cured material was removed from the glass and heated at 125, 175, and 225 °C to assess weight loss. Results are shown in Figure 6.

Summary

A number of acrylate-based secondary optical fiber coatings have been evaluated for property changes upon exposure to elevated temperatures. Of the materials tested, a coating consisting of specific types of urethane acrylate oligomers and hexanediol diacrylate diluent was the most resistant to weight loss, color change and increases in crosslink density upon exposure to temperatures from 125 to 225 °C. In addition, monomeric and oligomeric materials were also cured in neat form and aged at elevated temperatures. Oligomeric materials have been found that possess enhanced thermal resistance over that of the urethane and HDODA based coating. These results are part of the ongoing development of fast-curing technologies for higher temperature optical fiber applications.Acknowledgements

The authors would like to thank Cathy Ciardiello, Marketing Manager, Military & Sensing Applications, OFS Specialty Photonics Division; Robin Voigt, General Manager of Hexion UV Coatings (Shanghai); Dave Moberly and Mike Purvis, Hexion Specialty Chemicals, Louisville KY; and Dana Jones of Hexion’s Cincinnati Technical group, for their contributions to this work.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!