New Matting Agents for Waterborne Coatings and Varnishes

A good matte finish is often required in coatings formulations. In order to fully optimize this important parameter, Michelman has recently developed two wax dispersions: Michem® Guard 349 and Michem Guard 350. Both dispersions aid in imparting a matting effect to most aqueous coatings and varnishes, while enhancing other properties such as abrasion resistance and water repellency.

A good matte finish is often required in coatings formulations. In order to fully optimize this important parameter, Michelman has recently developed two wax dispersions: Michem® Guard 349 and Michem Guard 350. Both dispersions aid in imparting a matting effect to most aqueous coatings and varnishes, while enhancing other properties such as abrasion resistance and water repellency.

Characterized by a large particle size, both Michem Guard 349 and 350 extend the range of existing Michelman additives for surface modification in coating applications. Building on an existing range of water-based dispersions, these new wax dispersions are designed to highlight the positive properties of large-particle-sized wax and minimize unnecessary interaction from dispersing agents.

The degree of the so-created micro-roughness is determined by the number of particles present at the surface, which directly depends on wax properties such as: particle size and particle size distribution; particle density; and amount of matting agent incorporated.

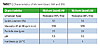

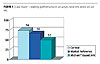

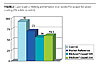

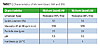

In all the case studies shown in Figures 1-3, performances of Michem Guard 349 and Michem Guard 350 were compared to a well-established matting agent considered as being a market reference.

In all the case studies shown in Figures 1-3, performances of Michem Guard 349 and Michem Guard 350 were compared to a well-established matting agent considered as being a market reference.

Samples of Michem Guard 349 or 350 can be obtained via the website, www.michem.com, or through the local agent and distributor network indicated on the website.

A good matte finish is often required in coatings formulations. In order to fully optimize this important parameter, Michelman has recently developed two wax dispersions: Michem® Guard 349 and Michem Guard 350. Both dispersions aid in imparting a matting effect to most aqueous coatings and varnishes, while enhancing other properties such as abrasion resistance and water repellency.

Characterized by a large particle size, both Michem Guard 349 and 350 extend the range of existing Michelman additives for surface modification in coating applications. Building on an existing range of water-based dispersions, these new wax dispersions are designed to highlight the positive properties of large-particle-sized wax and minimize unnecessary interaction from dispersing agents.

How Does a Wax Dispersion Control Matting?

As a coating film dries, wax particles are transported to the film surface as a consequence of the turbulence flow induced by the water evaporation. Because of the large particle size, protruding wax particles create a certain degree of micro-roughness, induced as the film shrinks. As a result, the incident light is scattered instead of being reflected, conveying the impression of low gloss or matte appearance.The degree of the so-created micro-roughness is determined by the number of particles present at the surface, which directly depends on wax properties such as: particle size and particle size distribution; particle density; and amount of matting agent incorporated.

Larger Particle Size Optimizes Appearance

Unlike wax emulsions – where the particle size is much lower than 1 µm – large-particle-size wax dispersions modify the optical properties of a coating. Not only do wax dispersions reduce gloss, as explained previously, but also significantly impact other surface properties. Formulations based on Michem Guard 349 and 350 will benefit from:- enhanced scratch, mar and abrasion resistance;

- improved barrier properties such as water repellency;

- enhanced slip and anti-blocking; and

- enhanced soft-feel.

- totally solvent-free;

- do not contain APE;

- reduced amount of surfactant;

- high solids content;

- no tendency for sedimentation;

- easy incorporation by single mixing; and

- no dust generation.

Application Areas and Processing Instructions

Typical application areas include: (a) wood coatings, particularly furniture and parquet lacquers; and (b) decorative and industrial coatings. Michem Guard 349 and 350 can be post-added with gentle mixing to ensure a homogeneous distribution. Selection of the appropriate matting agent depends on the dry film thickness. Optimum matting performances are obtained with dispersion particle size closely matched to the required dry film thickness. A level addition of 3% solids on solids is recommended to start with.

Case Studies

Both Michem Guard 349 and 350 have been successfully incorporated in various high-gloss paints and varnishes. Their performance in reducing the level of gloss is illustrated in Figures 1-3. High-quality, haze-free films were obtained in the case studies described in the figures. In all cases, the gloss was measured at 60° on a Leneta chart.

Samples of Michem Guard 349 or 350 can be obtained via the website, www.michem.com, or through the local agent and distributor network indicated on the website.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!