Waterborne Alkyds Break Through the Performance Barrier

With the introduction of waterborne acrylic (latex) technology more than 50 years ago, commercial coatings manufacturers found an alternative to traditional solventborne alkyd chemistries that had been the mainstay of the coatings industry until that point in time. Waterborne paint chemistry offered significant advantages to both manufacturers and end users of coatings, including easier clean-up and lower VOC content when compared to solventborne alkyds, which required significant amounts of organic solvent additives during the manufacturing process. However, the switch to waterborne chemistries did not completely eliminate the VOC content of acrylic-based coatings. All acrylics, particularly “gloss” acrylic latex formulations, require the addition of organic solvents to enable coalescence and coating film formation.

With the introduction of waterborne acrylic (latex) technology more than 50 years ago, commercial coatings manufacturers found an alternative to traditional solventborne alkyd chemistries that had been the mainstay of the coatings industry until that point in time. Waterborne paint chemistry offered significant advantages to both manufacturers and end users of coatings, including easier clean-up and lower VOC content when compared to solventborne alkyds, which required significant amounts of organic solvent additives during the manufacturing process. However, the switch to waterborne chemistries did not completely eliminate the VOC content of acrylic-based coatings. All acrylics, particularly “gloss” acrylic latex formulations, require the addition of organic solvents to enable coalescence and coating film formation.

Engineers at Reichhold Coatings Division have recently developed a new waterborne alkyd resin technology that uses advanced processing technology to produce a solvent-free alkyd formulation in a surfactant-stabilized aqueous emulsion. The soy-based resin, Beckosol AQ™ Alkyd Latex, provides all the benefits of a waterborne carrier with extremely low VOC content.

Water-reducible formulations came first, created by adding solvents and other expensive intermediates (including amines) to the alkyd base to facilitate water compatibility. But because the amines also tended to catalyze the process of hydrolysis, the resulting paint had a shelf life of six months or less. Another type of waterborne alkyd formulation developed was the “core-shell” hybrid, in which acrylics are added to an alkyd base to create a quasi-soluble mixture that is amine-neutralized to slow the process of hydrolysis. These formulations still required significant amounts of expensive alkyd intermediates and co-solvents, and shelf life of the resulting paint was only extended to 12 months.

Unlike previous waterborne alkyds, Beckosol AQ is a surfactant-stabilized emulsion and does not require expensive additives or co-solvents that attempt to solubilize the alkyd in the water carrier. The surfactant shell at the heart of Beckosol AQ’s formulation is formed by multiple micelles, or aggregates, which form when the hydrophilic “head” regions interact with the water solvent, forming the shell that surrounds the hydrophobic “tail” regions that cluster around the organic polymer within each micelle core. The result is that the concentration of water within each micelle “core” is extremely low, thus hydrolysis rates within the formulation are also extremely low, producing a paint with a shelf life of 12+ months. Figure 1 shows a depiction of a surfactant-stabilized alkyd-latex micelle in emulsion.

During the drying process, the alkyd’s polymer chains form crosslinks with exposure to oxygen, increasing the formulation’s molecular weight and improving its performance (Figure 3).

During the drying process, the alkyd’s polymer chains form crosslinks with exposure to oxygen, increasing the formulation’s molecular weight and improving its performance (Figure 3).

Acrylic latex-based coatings, by contrast, typically have a much higher molecular weight due to the chemical composition of their formulations. As such, the acrylic polymers within spherical latex particles will demonstrate very high viscosity and very little flow and leveling. As a result, they have comparatively poor substrate wetting properties and thus do not typically exhibit the same type of adherence and flow characteristics as their alkyd-based counterparts. Figure 3A shows this process in latex-based coatings.

The superior performance of alkyd-based coatings, however, has been offset by their high VOC content (due to the requirement for organic solvents used as carriers.) Latex-based coatings, using water as their solvent carriers, typically have significantly lower VOC content, but with the performance trade-offs noted above.

However, as coating technology advances and high-quality paints with low VOCs prove themselves in the marketplace, the regulatory agencies will eventually force lower VOC limits on the industry. Companies that adopt Beckosol AQ’s new alkyd latex technology now will be well positioned to compete in this changing marketplace when the next round of regulations force companies to reformulate.

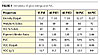

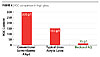

Figure 5 shows the current and projected future VOC limits of three major government regulatory bodies: SCAQMD (Southern California Air Quality Management District); CARB (California Air Resource Board); and OTC (Ozone Transport Commission), based in the northeastern United States. As shown, the SCAQMD standards will soon require coatings manufacturers to produce paint with no more than 50g/L VOC content in gloss, semi-gloss and flat formulations. CARB and OTC standards are expected to move toward these limits by 2010.

Using Beckosol AQ’s new alkyd latex resin technology, coatings manufacturers can achieve these VOC limits today, and be in compliance with current and future limits for several years to come without the need to reformulate.

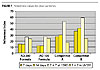

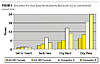

The comparison is especially dramatic for the 30-minute/120 °F block test, as shown in Figure 11.

The comparison is especially dramatic for the 30-minute/120 °F block test, as shown in Figure 11.

For more information, visit www.reichhold.com.

With the introduction of waterborne acrylic (latex) technology more than 50 years ago, commercial coatings manufacturers found an alternative to traditional solventborne alkyd chemistries that had been the mainstay of the coatings industry until that point in time. Waterborne paint chemistry offered significant advantages to both manufacturers and end users of coatings, including easier clean-up and lower VOC content when compared to solventborne alkyds, which required significant amounts of organic solvent additives during the manufacturing process. However, the switch to waterborne chemistries did not completely eliminate the VOC content of acrylic-based coatings. All acrylics, particularly “gloss” acrylic latex formulations, require the addition of organic solvents to enable coalescence and coating film formation.

Engineers at Reichhold Coatings Division have recently developed a new waterborne alkyd resin technology that uses advanced processing technology to produce a solvent-free alkyd formulation in a surfactant-stabilized aqueous emulsion. The soy-based resin, Beckosol AQ™ Alkyd Latex, provides all the benefits of a waterborne carrier with extremely low VOC content.

Low VOCs vs. Paint Performance Characteristics

Until the development of Beckosol AQ, coating manufacturers faced a trade-off between the reduced VOC content of waterborne acrylics (latex) and the superior performance in real-world applications of conventional solventborne alkyds in gloss rating, adhesion rating and stain-blocking abilities. Thus, coatings formulation engineers began experimenting with a way to combine the long-lasting, high-gloss performance characteristics of alkyds with the low-VOC, easy-to-use features of waterborne acrylics.Water-reducible formulations came first, created by adding solvents and other expensive intermediates (including amines) to the alkyd base to facilitate water compatibility. But because the amines also tended to catalyze the process of hydrolysis, the resulting paint had a shelf life of six months or less. Another type of waterborne alkyd formulation developed was the “core-shell” hybrid, in which acrylics are added to an alkyd base to create a quasi-soluble mixture that is amine-neutralized to slow the process of hydrolysis. These formulations still required significant amounts of expensive alkyd intermediates and co-solvents, and shelf life of the resulting paint was only extended to 12 months.

Unlike previous waterborne alkyds, Beckosol AQ is a surfactant-stabilized emulsion and does not require expensive additives or co-solvents that attempt to solubilize the alkyd in the water carrier. The surfactant shell at the heart of Beckosol AQ’s formulation is formed by multiple micelles, or aggregates, which form when the hydrophilic “head” regions interact with the water solvent, forming the shell that surrounds the hydrophobic “tail” regions that cluster around the organic polymer within each micelle core. The result is that the concentration of water within each micelle “core” is extremely low, thus hydrolysis rates within the formulation are also extremely low, producing a paint with a shelf life of 12+ months. Figure 1 shows a depiction of a surfactant-stabilized alkyd-latex micelle in emulsion.

Air Crosslinking - the Key to Performance

Alkyd-based coatings typically have better performance characteristics than conventional latex-based coatings in adhesion, penetration, gloss development and stain blocking. Because alkyd formulations have a low molecular weight, a relatively flexible polymer chain and a low glass transition temperature (Tg), they have superior substrate wetting properties; that is, they tend to flow better and have more adhesion to the surface being coated. Figure 2 shows this process in alkyd coatings.

Acrylic latex-based coatings, by contrast, typically have a much higher molecular weight due to the chemical composition of their formulations. As such, the acrylic polymers within spherical latex particles will demonstrate very high viscosity and very little flow and leveling. As a result, they have comparatively poor substrate wetting properties and thus do not typically exhibit the same type of adherence and flow characteristics as their alkyd-based counterparts. Figure 3A shows this process in latex-based coatings.

The superior performance of alkyd-based coatings, however, has been offset by their high VOC content (due to the requirement for organic solvents used as carriers.) Latex-based coatings, using water as their solvent carriers, typically have significantly lower VOC content, but with the performance trade-offs noted above.

Alkyd Performance Breakthrough

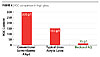

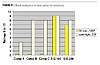

The introduction of Beckosol AQ resins provides the coatings industry with the ability to develop formulations that have alkyd-like performance using water as the primary carrier, thus achieving near-zero VOC content. Figure 4 shows the comparison of the VOC content in a conventional solventborne alkyd with that of a typical gloss latex enamel and of gloss trim made with Beckosol AQ.

Rethinking Formulations with Lower VOCs

One of the primary benefits of Beckosol AQ latex alkyd technology for coatings manufacturers is the ability to improve performance while meeting tighter VOC requirements well into the future without the need to constantly reformulate. As regulatory bodies attempt to continually lower the VOC limits, paint companies have been faced with the need to reformulate. But because of the performance limitation of conventional low-VOC formulations, many paint companies have justifiably argued that the current low-VOC technology will produce coatings without the performance quality or durability ratings, and thus will result in higher levels of VOCs (painting with low-VOC paints twice within five years vs. just once with the higher VOC alternative.)However, as coating technology advances and high-quality paints with low VOCs prove themselves in the marketplace, the regulatory agencies will eventually force lower VOC limits on the industry. Companies that adopt Beckosol AQ’s new alkyd latex technology now will be well positioned to compete in this changing marketplace when the next round of regulations force companies to reformulate.

Figure 5 shows the current and projected future VOC limits of three major government regulatory bodies: SCAQMD (Southern California Air Quality Management District); CARB (California Air Resource Board); and OTC (Ozone Transport Commission), based in the northeastern United States. As shown, the SCAQMD standards will soon require coatings manufacturers to produce paint with no more than 50g/L VOC content in gloss, semi-gloss and flat formulations. CARB and OTC standards are expected to move toward these limits by 2010.

Using Beckosol AQ’s new alkyd latex resin technology, coatings manufacturers can achieve these VOC limits today, and be in compliance with current and future limits for several years to come without the need to reformulate.

Performance Testing

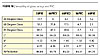

Extensive performance testing was conducted comparing Beckosol AQ alkyd latex resin technology with commercially available exterior wood stains for dry times, color stability and weatherability; as well as comparison to traditional waterborne latex acrylic formulations for gloss rating, block resistance, adhesion and stain blocking characteristics. In all test procedures, Beckosol AQ demonstrated superior performance at VOC levels well below the regulatory limits currently in place.

Fast-Drying Clear Base Formulations

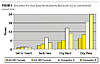

In both long oil (Beckosol AQ 100) and medium oil (Beckosol AQ 200) formulations, the new alkyd latex resins exhibited faster dry times than commercially available wood stains, as shown in Figure 6. At each measurement point on the drying scale (set-to-touch, tack-free, dry hard and dry-through), Beckosol AQ showed significantly shorter drying times.

Non-Yellowing in Clear Varnish Formulations

Beckosol AQ formulations using both long and medium oil alkyd latex resins demonstrated superior resistance to yellowing, at 7 and 14 days, and with elevated temperatures (150 °C) and prolonged exposure to UV light sources, as shown in Figure 7.

Weathering

Preliminary weatherability analysis indicates that Beckosol AQ alkyd latex resins offer superior weatherability on high tannin wood surfaces (cedar), as shown in Figure 8.

Full Range of Gloss Ratings, PVC Possible

Beckosol AQ alkyd latex resins enable a broad range of pigment volume concentration (35% to 60%), as shown in Figure 9; and a full range of gloss ratings (20 degree, 60 degree and 80 degree), while maintaining VOC levels below 16g/L (Figure 10).

Superior Block Resistance

In a semi-gloss formulation, both long oil (Beckosol 100) and medium oil (Beckosol 200) alkyd latex resins provide superior block resistance when evaluated against commercially available low-VOC paints.

Adhesion

In a test of adhesion to weathered, chalky latex surfaces, the Beckosol AQ alkyd latex resins (in gloss, semi-gloss and flat formulations) exhibited much better adhesion ratings when compared to both stain-blocking and all-purpose water-borne primers, as shown in Figure 12.Conclusion

The introduction of Beckosol AQ alkyd latex resin technology combines the performance advantages of alkyd-based paint chemistries with the convenience of solvent-free, waterborne coatings, with near-zero VOC content. Coatings manufacturers are no longer forced to trade performance and durability for the low-VOC levels needed to meet ever-tightening regulatory standards. By selecting Beckosol AQ as the primary resin for near-zero VOC coatings, manufacturers can eliminate the expense of reformulation to meet these new VOC requirements, as well as VOC exceedance fees.For more information, visit www.reichhold.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!