Breaking the Performance Barrier in Automotive Interiors

The polymers used to protect and beautify interior automotive plastic coatings need to be top performers.

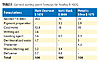

The U.S. automotive industry has gone through huge transformations in the past 30 years, starting with the structure of the industry, where the dominance of the Big Three has been challenged by global players. Improvements in on-the-road performance have made exponential step changes as well. The performance improvements cover multi-dimensional aspects like fuel efficiency, robustness, safety features and comforts to name a few (Table 1).

Credit: DSM NeoResins Credit: DSM NeoResins

|

| Table 1 Click to enlarge |

Interior automotive design has also undergone broad changes to improve ergonomics, functionality and appeal. Not the least of these is the expanded use of durable plastic materials, which now account for the majority of the human-contact surfaces.

In this article, we focus on the needs of interior car coatings. These coatings are driven by three criteria: look, feel and functionality. While look and feel are a function of fashion trends and are relatively short lived, the demands in functionality are usually step changes in terms of physical and chemical resistance properties which, in turn, are intended to preserve the look and feel of the coating.

Automotive Interiors: A Pleasurable Ride

Interior automotive surfaces like door trim panels, instrument panels, dashboards and center consoles are often exposed to a broad array of chemicals as a result of daily use. Just considering the ingredients found in food and personal care items, cleaners and dressings, deodorizers and pet products; interior surfaces must be resistant to chemicals, which can be oleophilic or hydrophilic; acidic or alkaline; and solvents like alcohols, glycol ethers and hydrocarbons. Chemicals particularly harsh to interior surfaces include sun tan lotion, mosquito repellant (DEET: N,N-diethyl-meta-toluamide) and the freshness fragrances that make driving a more pleasurable experience. Now let’s raise the degree of difficulty by requiring protection at sub-zero and elevated temperatures to 140 ºF!

All global automotive players have defined standards for interior coatings so that they retain their look and feel in the face of these extreme conditions. For example, General Motors has developed the Global Approved Paint on Plastic Systems based on GM 14867 specification. These are usually one-component systems. On the other hand Volkswagen’s TL-226 specification has another set of stringent standards that typically use two-component systems in Europe.

Defining the Innovation Need

Coating suppliers to the interior automotive plastics market are often large multinational corporations or regional players who form global alliances in order to supply the OEMs across the planet. Local regulations and growing consumer sustainability awareness make the use of low-VOC waterborne systems a prerequisite for many of the surface protection coating systems. Subsequently, coatings need to have good atomization during application providing the “appearance” prescribed by the designer, high adhesion to ABS and PC-ABS plastics and protective properties to resist chemical and abrasion attack.

The GM Global Specification and VW TL-226 specifications for interior automotive plastic coatings have particularly defined the need to address the DEET/sun lotion attack on the coating systems. Both require resistance to attack under 80 ºC temperatures. To meet these demands, this multinational team of developers chose a polyurethane-hybrid polymer system.

Credit: DSM NeoResins Credit: DSM NeoResins |

| Table 1 Click to enlarge |

For application areas where the requirements are at a high level, urethane polymer chemistry forms a good basis from which new performance barriers can be reached.

Polymer Design

Various synthesis routes for high-molecular-weight polyurethane dispersions are common practice. Best know are the acetone process, the melt dispersion process, the ketamine process and the prepolymer mixing process. The first synthesis step of all these processes is the same, being a well-known polyurethane reaction in which diols or polyols are reacted with diisocyanates (Figure 1). Reaction product is then dispersed in water.

In the case of anionic polyurethane dispersions, the prepolymer chains contain carboxylic acid stabilizing groups provided, for example, by dimethylol propionic acid (DMPA). The prepolymer acidity is then neutralized and transferred to water, where spontaneous particle formation occurs. Chain extension is then carried out resulting in the formation of a high-molecular-weight waterborne polyurethane polymer dispersion. The very nature of the process results in the formation of a polymer colloid, which is significantly different from that of emulsion polymers. They differ in terms of their colloidal, morphological and application characteristics.

Credit: DSM NeoResins Credit: DSM NeoResins |

| Figure 2 Click to enlarge |

It is well understood that, in terms of particle and polymer morphology, polyurethane dispersions have a unique advantage over many other polymers in their ability to form coherent films. The degree of coalescence and the interpenetration of the polymer chains leading to further gradual coalescence of the particles are reported to be much higher for typical polyurethane than for a typical acrylic latex particle (Figure 2).

Critical to the superior film formation are two factors. First is the presence of water within the particle. Moisture content of the particle plays the roll of plasticizer in that it softens the particle thus making it easier to coalesce, as shown in Figure 3.

Credit: DSM NeoResins Credit: DSM NeoResins |

| Figure 3 Click to enlarge |

The second critical factor involves the nano-particle size of most polyurethane dispersions. During the coalescing process, particles are driven together by the evaporation of water from the coating. This “hydrostatic vacuum” forces the particles together the same way evacuating air between two surfaces binds them. The effectiveness of this process is relative to the surface area of particles. For a given mass of dispersed polymer, smaller particles will result in a greater surface area and a greater driving force.

Credit: DSM NeoResins Credit: DSM NeoResins |

| Figure 4 Click to enlarge |

Moreover, polyurethanes “generate” performance enhancement due to their ability to form micro-phase morphology, where hard segments and soft segments (segment phase separation) are manipulated to achieve suitable polymer packing resulting in enhanced hydrogen bonding (Figures 4 and 5). In designing new polymers to meet the new performance criteria this performance enhancer is addressed with special care.

Credit: DSM NeoResins Credit: DSM NeoResins |

| Figure 5 Click to enlarge |

Additionally, the inclusion of a polyurethane-hybrid design provided benefits that a polyurethane homopolymer or physical blend of resins could not. It is well understood that many of the physical performance improvements found in a hybrid design over a physical blend can be attributed to the homogeneity of the dried films.

The Atomic Force Microscopy (AFM) images, shown in Figure 6, are presented in the phase mode showing the hard and soft segment distribution of the polymer. The image on the left illustrates the incoherent phase distribution of two dissimilar polymers during film formation. The image on the right illustrates the homogeneous distribution of dissimilar polymer resulting from hybrid polymerization. A homogeneous distribution of these regions is important in maintaining the physical characteristics of the polyurethane. Nano-phase hybrid technology is regarded as an excellent way to reinforce coatings and improve their performance.

Credit: DSM NeoResins Credit: DSM NeoResins |

| Figure 6 Click to enlarge |

Meeting Performance Needs on Two Continents

The GM World specification for interior automotive plastics (GMW14867) contains demanding performance requirements for adhesion, humidity and impact, but the most demanding requirement is the resistance to chemical attack at 80 ºC (Table 2). GMW14445 utilizes a chemical cocktail comprised of equal amounts of: DEET, octyl methoxycinnamate, octocrylene, and homosalate.

Credit: DSM NeoResins Credit: DSM NeoResins |

| Table 3 Click to enlarge |

Of equal difficulty is the VW TL-226 specification, which requires 24 h resistance to hand cream and sun block lotion at 80 ºC (Table 3).

By means of intelligent raw material choices and proprietary polymerization techniques NeoRez R-4000 was developed to meet the resistance challenge of GMW 14867 and VW TL-226. NeoRez R-4000 is designed to be effective in both 1K and 2K coatings. Two-component coatings utilize a blend of hydrophilic and hydrophobic isocyanate adducts to achieve higher crosslink density that is required to meet the 24 h 80 ºC test. Performance test results are shown in Table 4.

Credit: DSM NeoResins Credit: DSM NeoResins |

| Table 4 Click to enlarge |

Formulation

NeoRez R-4000 can be compounded to meet the appearance needs for clearcoats, solid colors with varying grades of gloss and, of course, metallic (silver being the most popular). Waterborne coatings also need a shelf life of about six months, which demands good compatibility of the binder with the pigment preparation and additive alike. Starting-point formulations are shown in Table 5.

Credit: DSM NeoResins Credit: DSM NeoResins |

| Table 5 Click to enlarge |

To ensure good compatibility, all formulations should be prepared using a high-speed dissolver with each additive being carefully incorporated to avoid shock or flocculation. For two-component formulations, a (1:1) ratio of hydrophobic combined with hydrophilic isocyanate was added to a set amount of the one-component finished formulation under agitation (Table 6).

The final formula films where checked as drawdowns on glass for flocculation and incompatibility. The coatings were visually assessed then measured for gloss, haze and pigment float. The formulations were additionally stored at 50 ºC for 3 months and rechecked for quality and performance.

Credit: DSM NeoResins Credit: DSM NeoResins |

| Table 6 Click to enlarge |

Conclusion

It is well known that the performance standards for interior automotive plastic coatings have dramatically changed since plastics first appeared in the automobile cockpit. The standards established by General Motors and Volkswagen are amongst the most difficult to meet. But considering the plethora of chemicals, food items and reagents that may be residing on a coated plastic surface during mid afternoon sun in Phoenix it stands to reason that the polymers used to protect and beautify these substrates need to be top performers. NeoRez R-4000 is a new and effective polymer to help the formulator meet this challenge.

Acknowledgements

The authors convey thanks to Ilse Koks- van den Nouweland, Sandy Wheeler and Delia Kriticos for experimental application work, and Herman Ryborz and Stefan Geboers for contributing the numerous synthesis and not giving up.

This paper was presented at the Coatings for Plastics Symposium sponsored by PCI Magazine, Chicago, 2009.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!