Innovative Amine Curing Agents for Epoxy Resins

Recent advances in new amine functional curing agents have improved performance of waterborne two-package epoxy coating systems. These new amine adducts offer performance advancements along with the ability to meet low- and ultra-low VOC levels. This paper will summarize the performance of a new zero-VOC, water-soluble, amine curing agent in waterborne epoxy formulations with liquid epoxy resin at less than 50g/L VOC. We will review the performance of these new starting formulations against commercially available coatings for concrete.

This new waterborne curing agent is designed for cementitious applications in industrial and Do-It-Yourself (DIY) markets. Formulations based on this new amine curing agent demonstrate water-reducible epoxy coatings systems with superior handling, application properties, and visible end of pot life; combined with improved resistance to chemicals and staining.

Using new amine adduct technology, these waterborne epoxy systems offer uncompromised high performance, low VOC levels and the advantages of easy water clean up.

In this work, the new product design criteria and formulated performance design requirements will be summarized. Subsequent to this, the new curing agent’s properties and performance in formulated systems will be reviewed against commercially available products from the market.

Using the design criteria, a variety of experimental candidates were evaluated and screened. The best candidates were then formulated into concrete coatings and compared to predetermined performance requirements. The candidate meeting all of the criteria is now called EPIKURE™ Curing Agent 8547-W-60 (the new waterborne curing agent).

Having met the curing agent’s design requirements, four coating systems were formulated to quantify the resin’s performance in a formulated coating for cementitious applications against established criteria. The formulations (in Appendix I) are:

Then, the performance and chemical spot resistance of these coating systems (Table 2) were evaluated with a group of chemicals that are typically found in a residential garage and some common chemicals that are aggressive to coating systems.

Then, the performance and chemical spot resistance of these coating systems (Table 2) were evaluated with a group of chemicals that are typically found in a residential garage and some common chemicals that are aggressive to coating systems.

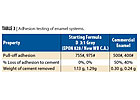

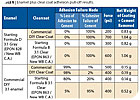

The adhesion properties of these epoxy coatings systems (Table 3) were also evaluated. It is interesting to note the mode of failure in the adhesion testing of these systems. The commercial DIY system exhibited lower adhesion in contrast to the new amine curing system, but the mode of failure was significantly different, too.

The adhesion properties of these epoxy coatings systems (Table 3) were also evaluated. It is interesting to note the mode of failure in the adhesion testing of these systems. The commercial DIY system exhibited lower adhesion in contrast to the new amine curing system, but the mode of failure was significantly different, too.

With this new waterborne amine, the mode of failure was only cohesive failure of the cement to a significant extent. Using the commercial water-based product, the failure mode was more adhesive failure at the coating interface to the cement, as well as some cohesive failure of the concrete (Figure 1).

With this new waterborne amine, the mode of failure was only cohesive failure of the cement to a significant extent. Using the commercial water-based product, the failure mode was more adhesive failure at the coating interface to the cement, as well as some cohesive failure of the concrete (Figure 1).

The key observation is that the starting formulation adhesion is much greater, and the amount of concrete removed was significantly more, than that exhibited by the commercial water-based product. During comparison of these various systems, it was found that only Hexion’s starting formulations based on the new waterborne curing agent and DIY #2 exhibited easy water clean up.

The key observation is that the starting formulation adhesion is much greater, and the amount of concrete removed was significantly more, than that exhibited by the commercial water-based product. During comparison of these various systems, it was found that only Hexion’s starting formulations based on the new waterborne curing agent and DIY #2 exhibited easy water clean up.

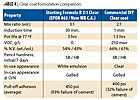

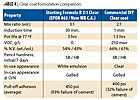

Following a review of the enamel epoxy coating systems, an evaluation of clear coating systems was performed. A similar procedure to compare the properties of a commercially available clear versus our formulated system was followed (Table 4).

The clear coating system based on the new amine curing agent exhibits excellent adhesion (Table 5). The mode of adhesion failures shown in the previous study was similarly exhibited in this study, too.

The clear coating system based on the new amine curing agent exhibits excellent adhesion (Table 5). The mode of adhesion failures shown in the previous study was similarly exhibited in this study, too.

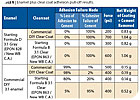

An unexpected result was exhibited when we evaluated the gray enamel plus clear systems. When the clear enamel (Starting Formula B) was used over the commercial enamel, the results showed superior adhesion, and ”pull-off” weights, when compared to the commercial clear coat companion system from the same supplier (Table 6).

An unexpected result was exhibited when we evaluated the gray enamel plus clear systems. When the clear enamel (Starting Formula B) was used over the commercial enamel, the results showed superior adhesion, and ”pull-off” weights, when compared to the commercial clear coat companion system from the same supplier (Table 6).

This paper was presented at The Waterborne Symposium, sponsored by The University of Southern Mississippi School of Polymers and High Performance Materials and The Southern Society for Coatings Technology, 2008, New Orleans, LA.

For more information, contact David Fernee, 281/325.3317, david.fernee@hexion.com or Tec-epon@Hexion.com.

This new waterborne curing agent is designed for cementitious applications in industrial and Do-It-Yourself (DIY) markets. Formulations based on this new amine curing agent demonstrate water-reducible epoxy coatings systems with superior handling, application properties, and visible end of pot life; combined with improved resistance to chemicals and staining.

Using new amine adduct technology, these waterborne epoxy systems offer uncompromised high performance, low VOC levels and the advantages of easy water clean up.

Introduction

Innovative waterborne epoxy binder systems have been advancing rapidly to answer the demands of lower VOC regulations and the market’s need for higher performance. Early versions of waterborne epoxy systems met the regulatory demands, but these coatings systems exhibited lower performance compared to their solventborne counterparts. In recent years, the performance of waterborne epoxy systems has greatly improved, thus meeting the higher performance requirements and allowing further reduction of VOC levels.In this work, the new product design criteria and formulated performance design requirements will be summarized. Subsequent to this, the new curing agent’s properties and performance in formulated systems will be reviewed against commercially available products from the market.

Design

For the development of this new product, a list of design criteria based on a review of curing agents currently available in the market was established. This assessment created a list of key curing agent design criteria. The design criteria included; ease of use, low viscosity, freeze/thaw stability, heat stability, dilution stability, and chemical inventory status. In addition to the curing agent’s design criteria, a list of formulation attributes and coating performance requirements of this new curing agent was established. This was based on paint producer input, current commercial products in the market and end-use customer interviews. The critical formulated properties included: PVC, mixed component viscosity, induction time, VOC, pot-life duration, gloss stability during pot-life, hardness development and good chemical resistance.Using the design criteria, a variety of experimental candidates were evaluated and screened. The best candidates were then formulated into concrete coatings and compared to predetermined performance requirements. The candidate meeting all of the criteria is now called EPIKURE™ Curing Agent 8547-W-60 (the new waterborne curing agent).

Having met the curing agent’s design requirements, four coating systems were formulated to quantify the resin’s performance in a formulated coating for cementitious applications against established criteria. The formulations (in Appendix I) are:

- Starting formulation A: Concrete gray primer, 4:1, semi-gloss

- Starting formulation B: Concrete topcoat clear, 3:1, high gloss

- Starting formulation C: Concrete topcoat clear, 3:1, high gloss

- Starting formulation D: Concrete gray primer, 3:1, medium gloss

Experimental

- Sample preparation and constant calculations – Samples were prepared using standard industry methods and raw materials. Reported coating constants were calculated using ASTM D 2369.

- Film preparation – Drawdowns were performed on Leneta Chart 5C at 5 mil wft, using a standard drawdown bar. Drawdowns on cement were performed using a 60-mil wire wound rod on acid washed cement blocks (4 x 6 x 1 provided by Patio Cement Products Inc.).

- Ambient conditions – All formulation components were equilibrated at 77 °F for 1 day before mixing. Drawdowns and films were applied at 77 °F and 50% R.T and then allowed to dry at the same conditions. All physical testing was performed at 7 days, unless noted.

- Hardness development – Pencil hardness was determined per ASTM D 3363 on the cement blocks.

- Pot life, viscosity and gloss measurements – Viscosity was determined per ASTM D 562. Gloss was measured at 60º geometry per ASTM D 523.

- Dry time – Determined using the BYK Circular Drying timer per ASTM D 5895.

- Chemical Resistance – Performed on prepared cement blocks per ASTM D 1308. MEK resistance was performed per ASTM D 5404.

- Adhesion testing (Pull off) – Performed per ASTM D 4541 using Elcometer 106 pull-off tester with the 2.0 cm dollie.

Results and Discussion

A number of commercially available products from the market were purchased for use in this study. These products’ properties were compared to the starting point formulation (Table 1).

Following a review of the enamel epoxy coating systems, an evaluation of clear coating systems was performed. A similar procedure to compare the properties of a commercially available clear versus our formulated system was followed (Table 4).

Conclusion

It has been demonstrated in this study that high performance and ultra-low-VOC coatings for concrete can be achieved with the use of a newly introduced waterborne curing agent (EPIKURE 8547-W-60). The introduction of this new technology into the commercial arena will give paint formulators an excellent new tool to meet existing and new regulatory hurdles without any sacrifice of performance. If the design criteria established in our interviews with end users, specifiers and owners is right, then this advancement in amine adduct chemistry will be a product the market will readily accept and adopt in the years to come.This paper was presented at The Waterborne Symposium, sponsored by The University of Southern Mississippi School of Polymers and High Performance Materials and The Southern Society for Coatings Technology, 2008, New Orleans, LA.

For more information, contact David Fernee, 281/325.3317, david.fernee@hexion.com or Tec-epon@Hexion.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!