A Sucrose Ester-Modified Long Oil Alkyd Emulsion

Sucrose ester oil technology (Sefose®, P&G) provides a viable alternative to glycerin-based oils for alkyd emulsions.

Credit: Cook Composites & Polymers Credit: Cook Composites & Polymers

|

| Figure 1 Click to enlarge |

Sucrose ester oil technology (Sefose®, P&G) provides a viable alternative to glycerin-based oils for alkyd emulsions. Sefose is a highly esterified sucrose polyester made from sugar and vegetable oils. Sucrose esters essentially consist of a sucrose backbone and natural fatty acid residues linked to sucrose through ester bonds (Figure 1). Up to eight fatty acid chains can be attached onto sucrose, offering a compact crosslinking structure to an auto-oxidizing paint system like an alkyd. This higher functionality of fatty chains provides increased hydrophobicity for water resistance, higher crosslink density for improved chemical resistance and faster dry than glycerin-based oils. This molecule is a winner of the 2009 Presidential Green Chemistry Challenge Award, presented jointly to CCP and Procter & Gamble by the EPA.

Although sucrose ester alkyds lend themselves to high solids solventborne resin systems, they can also be adapted to emulsion resin systems for formulation of very low-VOC waterborne coatings with high organic renewable content.

Credit: Cook Composites & Polymers Credit: Cook Composites & Polymers |

| Table 1 Click to enlarge |

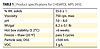

CHEMPOL® MPS 2410 is an example of this type of emulsion system. The sucrose ester molecule is incorporated into a traditional 70% solids long oil alkyd and emulsified. Product specifications are given in Table 1.

This emulsion gives excellent wetting to metal and plastic substrates, and excellent penetration to porous substrates such as wood and concrete. The low-molecular-weight sucrose ester component also aids in flow/leveling properties.

Formulation Suggestions

CHEMPOL MPS 2410 is very easy to work with and highly adaptable to current formulating techniques used in acrylic emulsion coatings. We recommend making a water/surfactant grind and then letting it down into CHEMPOL MPS 2410 with stirring. With the right pigment and dispersant it is possible to directly grind in CHEMPOL MPS 2410. In this case, pseudoplastic rheology is attained rather than thixotropic rheology, as with a water/surfactant grind.

Rheological additives are required to control pigment settling, sag resistance and application properties. Organoclays (Bentone® EW, AD) and associative thickeners (Acrysol® RM8W, Rheolate® 255) work well with CHEMPOL MPS 2410.

Due to its very low acid value, CHEMPOL MPS 2410 exhibits very good stability to inhibitive anti-corrosion pigments and reactive basic pigments like zinc oxide. Tamol® 165A or equivalent as a pigment dispersant is recommended in these formulas.

UV light stabilizer packages, if desired for enhanced UV resistance, should be incorporated using a solvent package such as mineral spirits or a glycol ether, which is known to partition in the center or near the surface of the particle.

Tint pastes designed for water-based coatings all seem to be compatible with CHEMPOL MPS 2410. For extremely low-VOC coatings, the Tint Ayd CW series is quite effective.

As with UV light stabilizer packages, the drier system should also be incorporated by dissolving in mineral spirits or glycol ethers before adding to the paint formulation. Use of cobalt chelating agents or dry accelerators should be avoided to reduce yellowing of the long oil alkyd. Borcher Oxicoat drier from OMG is particularly effective for fast dry and low yellowing properties.

Credit: Cook Composites & Polymers Credit: Cook Composites & Polymers |

| Table 2 Click to enlarge |

Paint Properties

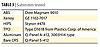

A white paint formula based on CHEMPOL MPS 2410 was used to evaluate properties. The white paint (Table 2) was applied using a syphon gun to various plastic and metal substrates, which were then tested for gloss, adhesion and water resistance. Substrates were sprayed out of box without any cleaning to 1.0 – 1.5 mils DFT and allowed to air dry 10 days before testing.

The substrates tested are listed in Table 3.

Credit: Cook Composites & Polymers Credit: Cook Composites & Polymers |

| Table 3 Click to enlarge |

Dry Times

Sucrose ester oil emulsions, from a drying point of view, behave identically to solventborne sucrose ester oil analogs – long set-to-touch times, followed by rapid surface hardness development.

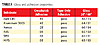

Several drier packages have been tried with the MPS 2410 resin system, some with better results than this example formulation. The drier system offering the fastest dry found to date has been Borchi® Oxy Coat, the new iron-complex drier from OMG. Incorporation of this drier in a similar formulation improves set-to-touch and dry-hard times: set-to-touch <1:00 and dry-hard 4-5 hours (Table 4).

Credit: Cook Composites & Polymers Credit: Cook Composites & Polymers |

| Table 4 Click to enlarge |

Gloss/Adhesion

Table 5 demonstrates the gloss and adhesion properties. Gloss was excellent over all substrates, with some reduction in 20º gloss over bare CRS. Tape-only adhesion was excellent for all substrates, but quite variable with a crosshatch, depending on substrate. Generally, best adhesion was observed over metal and TPO substrate. Some improvement in crosshatch adhesion was noticed after 3 weeks dry.

Film Properties

Table 6 shows the film properties after the paint was applied over bare CRS and air dried for 2 weeks before testing

Credit: Cook Composites & Polymers Credit: Cook Composites & Polymers |

| Table 5 Click to enlarge |

Household Chemical Resistance

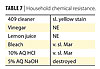

One-hour uncovered spot tests of several common household chemicals were conducted on an aluminum substrate. The film was washed with water and given 1 h and 24 h recovery before being rated (Table 7). No affect or significant difference was observed between CHEMPOL MPS 2410 and a conventional solventborne paint.

Credit: Cook Composites & Polymers Credit: Cook Composites & Polymers |

| Table 6 Click to enlarge |

Water Resistance

A characteristic found for CHEMPOL MPS 2410 was poor water vapor resistance over ferrous substrates, i.e., bare CRS. This is readily apparent in environmental testing, such as Cleveland Humidity or ASTM B 117 salt spray testing. This is believed to be caused by the emulsifier package for CHEMPOL MPS 2410. Solventborne analogs do not exhibit this water sensitivity.

Consequently, this emulsion is not recommended for DTM coatings over ferrous substrates. If it is used, a flash rust additive is required. However, use of a wash primer (SYNAQUATM 821-2220-N) or incorporation of anti-corrosive pigments, esp. zinc oxide, have been shown to significantly improve corrosion resistance.

Credit: Cook Composites & Polymers Credit: Cook Composites & Polymers |

| Table 7 Click to enlarge |

Summary

Recommended application areas for CHEMPOL MPS 2410 are architectural paints, including trim enamels, barn paint, stains, and porches and decks; as well as light-duty industrial products, such as rust-resistance enamels, plastic coatings (esp. TPO) and DTM coatings (use of wash primer required).

CHEMPOL MPS 2410 has significant advantages for those companies pursuing green chemistries. It provides highly renewable, biobased content, very low VOCs and excellent stability. Film properties equal to conventional solventborne alkyds are readily attained.

This paper was presented at the 2010 American Coatings Show in Charlotte, NC.

Suppliers/Acknowledgments

Dow Chemical (Rohm & Haas)

Acrysol associative thickeners

Tamol® pigment dispersant

Elementis

Bentone organoclays

Rheolate associative thickeners

Tint Ayd® waterborne tint paste

OMG

Borchi Oxy Coat drier

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!