A New Generation of Renewable, Non-Ionic Surfactants

More than ever before, the market for polymer dispersions today requires environmentally sound products that deliver state-of-the-art performance. Latex manufacturers are therefore looking to improve the performance of the final latex and to optimize the emulsion polymerization process in a sustainable way without sacrificing quality. The Disponil NG series of surfactants serves this demand: these surfactants are based on modified natural and renewable-based fatty alcohols combining state-of-the-art performance, handling and environmental soundness.

Gel-Free, Low-Foaming, Low-Pour-Point Surfactants

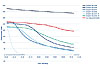

The Disponil NG series comprises surfactants that are suitable for all types of latices as in-process non-ionic or as post-stabilization surfactants. They show excellent phase behavior, meaning that when diluted with water, there are no gel phases over the entire concentration range. Additionally, they ensure rapid foam collapse in the surfactant solution as well as the finished latex, and they have low pour points, with one product specifically designed to reach even lower than -15 °C. These properties result in easier handling and reduced energy consumption during latex production compared to traditional surfactants. Emulsion production times are reduced, and the manufacturing process can continue even at very low temperatures. Moreover the low foaming properties of Disponil NG are also reflected in the end-use applications, e.g., in paints for outdoor applications. Being FDA-approved, they can also be used in food packaging applications, which makes them very attractive for areas such as paper latex manufacturing.Paula Gómez Perea, Senior Marketing Manager Coatings Europe at Cognis Functional Products, comments, “Cognis was one of the first companies to start searching for more sustainable alternatives to APEOs. We believe that these new renewable-based surfactants represent a new milestone: they offer convincing, easier-handling properties that help manufacturers to optimize and speed up their process and even improve final applications. This is what today’s market requires, so we believe they will give our customers a genuine competitive edge.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!