Integrated Tinting Systems

This article is Part 1 of a four-part series on converting to an integrated tinting system.

Paint manufacturers face many conflicting demands. Their clients have come to expect instant availability of high-quality, high-performing, reliable paints in every imaginable color. At the same time, ever-tightening VOC regulations need to be observed in a very competitive market environment. What appears like an impossible proposition is actually an excellent time to think about tinting systems more generally and to put one’s business on a stronger footing. As paint manufacturers are urged by regulatory bodies to convert their tinting systems to low-VOC colorant technology, they are also given an opportunity to rethink their set-up and make significant changes. Conversions are best managed in a comprehensive way, applying the principles of integrated tinting system design. For best results, paint producers need to understand both the benefits of integrated tinting and their own business needs. Working in partnership with a complete tinting systems solutions provider, they will be able to convert to a customized system that mitigates the above challenges while keeping total cost of ownership low.

Credit: CPS Color Credit: CPS Color |

| Figure 1 Click to enlarge |

There has been a concern with volatile organic compounds (VOCs) for many years, as some are known to cause potential harm to human health and/or the environment. VOC levels in paint are therefore carefully regulated but, so far in the United States, the contribution made by VOC-containing colorants has not been taken into account. With new legislation announced by the South Coast Air Quality Management District (SCAQMD) this is set to change. From January 1, 2014, VOC levels in colorants must not exceed 50 g/L for all architectural and water-based industrial coatings.(1) Paint manufacturers now have less than two years to prepare for the changes.

Many currently underestimate what the conversion to low-VOC colorants might mean to their business. Research published by the SCAQMD(2) has shown that very few paint manufacturers have given any thought at all to the changes, and of those who did, only a quarter are really aware of its implications. The majority of the respondents, particularly small- and medium-sized companies, admitted to not knowing what to expect in terms of time needed for the conversion, overall cost and training involved, or whether their existing dispensing equipment would be compatible with low-VOC colorants.

Credit: CPS Color Credit: CPS Color |

| Figure2 Click to enlarge |

Traditional Tinting Systems

The first step is to understand exactly what a tinting system does and the different types of tinting systems. Tinting systems for paints, designed to deliver the exact shade of color to customers, are based on standardized components, including colorants, dispensing and mixing equipment, control software and a color formula database designed to match the selected color marketing tools.

Most paint manufacturers aim to offer the broadest possible range of coating formulations and products to serve the diverse needs of their customers. In an effort to become more efficient, they adopted a universal colorant system for tinting a broad variety of products: from water-based latex architectural coatings to solventborne industrial maintenance coatings. Such systems typically consist of 12 universal colorants. While this works well in terms of offering a broad range of products at the point of sale, the paints’ quality may not always be entirely satisfactory due to the contribution of water from the universal colorants. Users of alkyd paints, for example, have a high demand for deep colors that can require a large colorant load. Introducing too much water into an alkyd product, however, can impair workability and application characteristics of the paint. Here, a solvent-based colorant would achieve a better result (Figures 1 and 2).

Credit: CPS Color Credit: CPS Color |

| Figure 3 Click to enlarge |

For example, 15% of a solvent-based colorant in a silk alkyd paint can be handled without a problem, while the addition of only 7% universal colorant will significantly reduce the gloss level of the coating (Figure 1). However a high-gloss alkyd paint with 7% universal colorant may require a longer drying time (Figure 2).

One way around this problem is to operate a dual system, which is one that consists of two sets of colorants, one water-based, one solvent-based. This ensures maximum compatibility with the base paint – but it can lead to problems with the colorants themselves. Doubling the number of colorants means that the consumed quantity of colorant declines by half on average. Some colorants, such as violet-red or magenta, are only used in very small amounts to less than one liter per year. This means they remain in their canisters for too long and may start to thicken or deteriorate, causing problems within the dispenser (Figure 3).

The picture becomes clear: whether single or dual, users of traditional, water-based, universal colorant systems either face limitations in terms of paint quality and characteristics, or experience adverse effects on colorant and equipment quality. If they replace their current lines with corresponding ones stripped of VOC-containing additives, they may well conform to incoming regulation, but the other difficulties will remain. What’s more, a simple “pour-over” is set to introduce further issues, as companies already experimenting with such a solution reported in the AQMD colorant survey. Half of them reported problems with clogged and dried-up nozzle tips, and some experienced variable viscosity and lack of compatibility in terms of gloss, water sensitivity and other features. Generally, low-VOC colorants are known to pose challenges with storage, mold growth and surface drying.

Credit: CPS Color Credit: CPS Color |

| Figure 4 Click to enlarge |

The Conversion Question

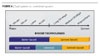

Conversion to a low- or zero-VOC colorant system is the only option due to legislation. However, the key is to select a new tinting system that will deliver the best possible long-term results for the individual business needs; in other words, to convert to an integrated tinting system. Such a system is more than the sum of its parts. It is a comprehensive approach to tinting system design that is customized to meet the business objectives of the individual paint manufacturer. Design of such systems requires thorough analysis of the manufacturer’s current business model and future objectives. It also demands intimate technical knowledge of all tinting system components to optimize and fine tune the performance of each element: colorants, dispensing and mixing equipment, control software and a color formula database design.

The Best of Both Worlds

For one business we examined alkyd coatings technologies, an important business segment for this paint producer. Therefore, a customized colorant set was selected to combine the advantages of a single universal system with those of a dual system. Water-based colorants are paired with a selection of UV-resistant, high-performance colorants plus economical colorants for the universal and solvent-based ranges. Such a system may, for example, consist of 24 colorants in total: 10 water-based, six universal and eight solvent-based ones. Colorants that are only needed in small quantities are set up as universal colorants. They can be used with both water-based and solvent-based systems, increasing their consumption.

Since color formulas contain only minor amounts of magenta or violet, their impact on the performance characteristics of the final product is minimal. It is important to integrate rules into the color formula database to ensure that only compatible colorants can be chosen with a selected product. Silicate and silicone-based paints, for instance, can only be tinted with water-based and universal colorants. While unlimited amounts of solvent-based colorants can be added to alkyd-based products, universal colorants may only be added in small amounts. This helps define the perfect balance between cost/performance and consumption of each individual colorant (Figure 4).

An Integrated Concept

The challenge of a comprehensive, advanced tinting system extends beyond combining the colorants and color formulas. Proper configuration of the entire tinting system, including dispensing equipment, must be considered. Customization of a dispenser begins with an analysis of the retailer’s business model and average tinted sales volume. This will determine the speed requirements to properly serve the end-user customer. Once that is determined, the dispenser type must be carefully matched to properly support the colorant technology and established set of colorants.

The behavior of the colorants over time within the dispenser must be also considered. Their various characteristics, including abrasiveness and speed of sedimentation or drying, could have a negative effect on the lifetime of pumps, valves or other mechanical parts. The right dispensing technology or even a combination of different technologies should be carefully considered. Further, it is important to select the optimal canister sizes and determine suitable stirring and recirculation needs for each individual colorant (see sidebar). This will help ensure that the colorant remains fresh in the canister, which will help minimize maintenance interventions.

The Formula of Color

Creating an accurate formula database is a critical part of integrated tinting system performance. The correct color formula rules ensure that the appropriate colorants are selected to achieve desired performance characteristics; for instance, UV-resistant colorants are used with exterior products. They minimize the overall formulation cost and optimize colorant consumption between all single colorants, meaning each single colorant should achieve a reasonable turnover to overcome technical problems.

Through this process, a small selection of the color formulas may turn out to be more expensive than they previously were. However, the overall improved performance of the system will balance this out in the end. Maintenance costs and down times will be minimized as throughput of slow-moving colorants is improved. Lower total cost of ownership and superior tinting system performance are the ultimate objective of integrated tinting solutions.

Responsible Service

Service is another key part of the tinting process that should not be overlooked. As integrated tinting systems are designed to fine tune all tinting components, it is important that the service provider be well versed in both the mechanics of the equipment and the characteristics of the colorant set. True tinting system support is best provided by a global network of trained specialists in colorants and system technology, who are able to modify existing systems and provide consultative assistance in case of problems. Choosing a partner who is responsible for the performance of all components of an integrated tinting system is a true competitive advantage.

Consultative Services

When setting up a truly integrated tinting system, it is important to make the right strategic business decisions throughout the design phase that create a sustainable, competitive advantage for the paint manufacturer. By working with a partner, capable of understanding all aspects of tinting system design, paint manufacturers can be assured that their business priorities will be achieved. Once implemented, only a supplier with comprehensive capabilities will be responsible for the long-term functionality of the complete integrated tinting system.

Environmental Regulations - Not Just for Southern California

As with many environmental legislative trends, what starts in Southern California quickly makes its way across the country. Is your company ready to implement upcoming changes to environmental legislation? The questions below will help to determine your own business readiness. If you are like many paint producers, you will find several questions difficult to answer. That is when a comprehensive tinting solutions provider can consult with you to design a system that will serve your company for years to come.

- Are you currently conducting research and development on near zero-VOC colorants?

- What is the timeframe to complete development and testing of a new near zero-VOC colorant system?

- Do you have the technical resources in terms of lab personnel and equipment to complete a colorant technology conversion?

- What are the steps involved in a colorant technology conversion to near zero-VOC colorants?

- Will you need to adapt your color formula database or color formulation parameters to optimize performance of a new colorant system?

- What is the expected timeframe to implement a change-over from glycol-containing to near zero-VOC colorant technology?

- Will a near zero-VOC colorant system be compatible with your current, installed base of dispensing equipment?

- What issues do you expect to experience in your point-of-sale operations as a result of a conversion to near zero-VOC technology?

- What is the cost associated with retrofitting existing tinting equipment to meet the requirements of a near zero-VOC colorant system?

- Is it preferable to invest in new dispensing equipment to avoid problems in the field, such as frequent mistints and maintenance downtime?

- What is the one-time cost associated with a colorant technology conversion?

The second article will delve deeper into the area of colorant technology to find new ways to deliver a sustainable advantage for your business. We will explore the colorant options beyond the traditional, commoditized, 12 colorant set, including high-strength colorants and colorants for specialized applications such as façade coatings.

For additional information, contact Bart Wilbanks, Technical Account Manager, Colorants, CPS Color, at 800-728-8408 or 704-588-8408 ext. 240.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!