Pretreatment Shining Brighter

The introduction of more environmentally friendly cleaning compositions has been coupled with various types of equipment to help companies handle pretreatment in more cost-effective ways. Conditioning is critical in a zinc phosphate process, and newer innovations in the chemistry of this step can reduce operating costs, while maintaining high quality standards. Some newer options are focused on completely new technologies that break with traditional methods altogether.

Traditional pretreatment

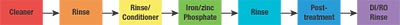

Typical pretreatment arrangements use anywhere from three to seven stages to clean and phosphate a metal part. The specific arrangement depends on the substrate and the quality requirements of the product.A majority of pretreatment lines used for high-performance applications are set up as follows: cleaner, rinse, condition rinse (if necessary), iron or zinc phosphate, rinse, post-treatment and a low-conductivity rinse (Figure 1). A critical step in this process is the complete removal of all surface contamination. Most metal parts use oil-based products in the machining or forming processes and require an alkaline-based cleaner to properly remove the oil from the surface.

In addition, the metal is sometimes welded in some form, leaving a scale that must be removed, usually by an acid-based cleaner. Both types of cleaners are typically composed of surfactants to help displace and solubilize contaminants and other agents used to soften water, inhibit etching of the substrate or dissolve metal ions.

Cleaners with surfactants that have an alkylphenol base have been widely used in the industry, mainly because they work well and are relatively inexpensive. However, alkylphenols are being phased out because of links to potential health problems. Canada, as well as most European countries, regulate against their use. As a result, companies are switching to nonphenolic-based surfactants in popular cleaners used in the United States in advance of stricter local regulations.

The treatment of contaminated cleaners can be an expensive process, usually requiring special chemicals and an on-site water-treatment facility. Companies are continuously looking for ways to reduce their waste-treatment costs and reduce the floor space required for the treatment system. New types and designs of micro-filtration, ultrafiltration, and reverse-osmosis systems are helping to meet these goals by taking care of the cleaning solution at its source, reducing contamination downstream.

With micro-filtration, a portion of the cleaner solution is continuously processed through a filter unit, where the oil is separated and diverted to a side container of some sort for easier and less-costly disposal. The main issue with these types of units is that the surfactant is usually dispersed with the oil, which reduces the solution's ability to clean. As suppliers gain a better understanding of the chemistry related to the cleaning process, they are developing more efficient system designs, better types of filters and filterable-surfactant-based cleaners.

Conditioning

Coaters utilize some type of phosphate process as a metal pretreatment prior to paint application. For higher-quality requirements, zinc phosphate is commonly used, which can create issues with heavy-metal ions in the wastewater effluent stream.New technologies that provide the same high-quality performance are now available that do not contain nickel, an increasingly regulated heavy metal. Other new processes are internally accelerated, which helps in overall operating-cost reductions and ease of operation.

Titanium-based conditioners historically have been used in the stage prior to a zinc phosphate application, basically providing nucleating sites to promote zinc phosphate crystal formation. The main drawbacks to these types of conditioners are that they become unstable with time and the buildup of typical hard-water salts, and they are difficult to accurately measure. Free titanium, which is the active component of these types of conditioners, is also very difficult to measure in most paint-line laboratories, which can create quality control issues.

Recently, a new type of conditioning chemistry has been developed that is more stable in hard water and over time. Improvements in the performance results of a zinc phosphate system, especially on difficult-to-coat substrates and box sections, have also been demonstrated. This is mainly due to a more complete zinc phosphate coating being consistently produced when using the new conditioner compared to using the traditional titanium-based product, regardless of the substrate. This is important because many lines are multimetal, meaning both aluminum and steel substrates are processed through the same tanks, and the quality of the coating is expected to be similar.

This new technology also allows the zinc phosphate crystals to form more quickly. In lab testing using the new conditioner, zinc phosphate coating weights in the 225- to 250-mg/ft2 range were obtained after a contact time of only 30 seconds. In that same amount of time using a titanium conditioner, the coating weights produced were only in the 175- to 190-mg/ft2 range. This can be a benefit in plants looking to reduce capital expenditures on new lines because smaller systems can be built while producing the same high-quality paint finish.

A final advantage is that the new conditioner is easier to control and produces more-reliable test results. A simple titration and pH meter are all that is required to ensure that the conditioner is operating in the recommended ranges. This is compared to the more-subjective, less-reliable colorimetric test required for titanium-based products.

Exceptional corrosion resistance

Zinc phosphate is the most commonly used type of pretreatment for electrocoat applications and other organic finishes that require exceptional corrosion resistance. The most popular products in this market contain some combination of zinc, cobalt, nickel and manganese metal ions.Nickel has been identified as a hazardous chemical and is becoming more strictly regulated. This results in a negative cost impact on paint shops because they have to pay to have the nickel treated in one way or another to prevent it from reaching the local municipality.

Also, OEMs are increasingly restricting the amount of nickel that can be contained in the parts they receive from their suppliers. New nickel-free zinc phosphates are now available that help to provide the same high-quality corrosion protection provided with zinc phosphates containing nickel, without significantly impacting the bottom line.

Also new is the use of an internal accelerator built into the product. This is significant because more-reliable automated line control and reduced phosphate sludge formation can be achieved. Existing zinc phosphate lines typically are controlled manually by adding two chemicals separately: one to replenish the zinc phosphate and one to replenish the accelerator. The only way to control this automatically is to add both products in proportion to one another.

Although frequently used, there is not much of an advantage since the bath still requires regular monitoring by line operators to make sure the concentrations stay within desired ranges. This is because, in most cases, the accelerator is sodium nitrite, which is depleted not only through production, but also over time as it oxidizes with the acidic zinc phosphate solution.

This hinders proportional additions because the accelerator will tend to deplete faster than the zinc phosphate solution. Another negative of the external accelerator is that it forms a small amount of sludge as it is added to the bath, especially if added too quickly, increasing the amount of maintenance needed to keep the tanks clean.

With the internally accelerated zinc phosphate, there is only one product that is regularly added to replenish the bath solution. Since the accelerator package is much more stable in the phosphate solution, its depletion rate is much lower.

This makes automated control much more feasible. It's also more cost-effective for the plant because the operators spend less time adding chemistry to the tanks or monitoring chemical concentrations. Automated control also improves line quality because it maintains tighter control over the parameter ranges.

Historically, post-treatments were based primarily on chromic acid. However, because hexavalent chrome is known to be a hazardous chemical, its use is becoming much more regulated. This is forcing paint shops to look at other options, such as fluorozirconic acid or polymer-based products. Newer polymeric chemistries have recently been developed that have proven to provide the same high-quality corrosion protection as chrome with a wider variety of substrates and paints.

Nontraditional pretreatment

As beneficial as some of the ideas discussed above are, the pressure to reduce costs and meet ever-tightening environmental regulations can be so great that some paint shops are forced into looking at nontraditional approaches. The most promising concept is the use of a nonphosphated pretreatment system (Figure 2). The technology that is the basis of this system is a phosphate-free chemistry that operates at ambient temperatures.Corrosion-protection testing has shown that this system is comparable to an iron phosphate/nonchrome post-treatment combination. With a proper design, this system can be built with a minimum of only four stages. This can have a very significant financial impact on the operational costs of existing systems and the amount of capital required to install new systems.

In existing systems, costs due to labor and water usage can be reduced since there are fewer tanks to operate and maintain. Energy costs will also be lowered by eliminating the burners normally required to heat the phosphate stage, since the new product runs at ambient temperatures.

For new systems, the need for fewer tanks will result not only in lower capital expenditures on labor and materials for tank construction and equipment, but less floor space will be required. This offers the plant more flexibility in determining where the system can be installed.

Another major advantage is that there are no phosphates or heavy metals in the chemistry of this product. Plants that are located in areas with tough environmental restrictions now have a viable option that may not require costly water treatment equipment or chemicals.

There are many options that are now available to reduce the costs of operating a pretreatment system and meet the ever-constricting environmental regulations. In addition to improvements on the traditional pretreatment, there is now a nontraditional option available for some finishers.

An important consideration, however, is that not all pretreatment systems are the same. When considering upgrading an existing system or building new lines, many factors must be considered and tested before making changes. The suppliers of the chemistry and equipment can usually offer advice and recommendations on which technologies best meet the needs of the system.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!