Faster, Friendlier and Fewer Rejects

Mike Jones, Unit Parts' director of process coating and finishing, was given the task of investigating and ultimately recommending a solution. Based on his previous experience in the paint industry and ownership of a powder coating shop, Jones' first instinct was to install a powder line and benefit from the positive features of powder coating technology, namely ease of application, environmental friendliness, and the ability to reclaim and reuse the powder.

However, there were challenges with installing a powder coating system. A conventional powder system would have required installing the cure oven and cooling tunnel on the roof of the facility due to floor space limitations. A powder system would also have required much more work in process (approximately 40 minutes total cycle time) than the company's conventional coating system. In addition, there were concerns about a production bottleneck. The system would not allow Unit Parts to process its heat-sensitive subassemblies, another transition from its current process.

In 1999, Jones attended the Finishing Show in Cleveland, looking for paint options other than powder. At the show, he was exposed to 100%-solid UV-pigmented coatings. A manufacturer of 100%-solid UV coating introduced Jones to its coating technology, which led him to re-evaluate the decision to install a new powder system.

100%-solid UV coatings

100%-solid UV coatings are cured using various wavelengths of ultraviolet light. UV coatings are formulated with 100%-solid reactive liquid vehicles, such as oligomers, monomers, photoinitiators, additives, resins and catalysts. A unique feature of 100%-solid coating is that the wet-film thickness is close to the dry-film thickness when cured. The monomers and oligomers react within the coating rather than flash off the coating. Pigments may be applied to the coating to color match practically any color, with the exception of a few shades of yellow and orange.Considerations for handling UV coatings revolve around the fluid delivery and surrounding atmosphere where the coatings will be applied. All wetted components in the fluid stream must be made of stainless steel or Teflon. Fluid lines should be opaque, and light sources should be filtered where exposure of the coating is possible. UV coatings are shear-sensitive and are not compatible with piston or gear pumps.

In addition, variation in coating temperature may have an adverse effect on applying paint to the substrate. Cooler temperatures may raise the viscosity, making it difficult to atomize and apply the proper film build. Heating the material slightly above ambient temperature helps alleviate variation in outside temperature.

Selecting UV coatings

100%-solid UV coatings were selected because of their low-temperature process, low VOCs and instantaneous cure time. The low-temperature process is ideal for heavy metallic parts, which would typically require a long cool-down time if cured in a conventional thermal oven. Moreover, temperature-sensitive components on internal assemblies are not affected.Other benefits of UV coating are its high abrasion and stain-resistance properties. Unit Parts' finished product was subjected to multiple processes after coating and had to be durable enough to withstand handling. Finally, the part had to look superior to the competition's part. 100%-solid UV coatings provided Unit Parts the finished product it was looking for.

"I recognized that UV technology was on the cutting edge," Jones says. "I knew that there would be a lot of R&D dollars involved and that the technology would advance very quickly. We wanted to get in, get situated and then wait for the technology to catch up."

Developing the process

Unit Parts conducted preliminary testing at two equipment suppliers' facilities. Coating samples from two different vendors were evaluated at each facility. Testing was required to determine the film thickness needed to achieve the customer's performance properties. Lamp suppliers were involved in the testing to match the correct wavelength of the bulb with the photoinitiator in the coating.

The testing was conducted on a portable chain-on-edge system. Once the preliminary testing was conducted, Unit Parts assembled the team that would be responsible for implementing the technology at its facility.

The final process

Once the parts are manually loaded onto the conveyor, they enter the spray booth and are rotated in front of a rotary atomizer. The spray booth design incorporates stainless steel baffles to collect the majority of overspray coating. The overspray is collected in a stainless steel trough and then pumped into a container for recycling.UV materials may be applied with a wide variety of application equipment. Unit Parts chose a rotary atomizer for its application. A rotary atomizer uses centrifugal force to atomize the coating, which is essential due to the typical high viscosity of 100%-solid UV coatings. The rotary atomizer also uses electrostatics to yield high transfer efficiency to the substrate, minimizing waste.

A heated, recirculating fluid-delivery system was used to maintain proper viscosity of the paint independent of the plant temperature. The paint was heated slightly higher than typical summer ambient temperatures. Once the parts are coated, they immediately enter the UV chamber where they are cured with four lamps within several seconds. The UV chamber was designed to be large enough to allow operators easy access to the lamps and to provide a window for viewing the parts.

Unit Parts chose microwave lamps because of their reliability and extended bulb life. Flexible mounting provides Unit Parts the ability to add additional capacity to the system based on line speed and part geometry.

Once the parts are cured, they exit the UV chamber through a shrouded chamber that provides a safe working environment for the operators. The finished product is cured and ready to be unloaded. The parts are then manually unloaded and placed in dunnage prior to final assembly.

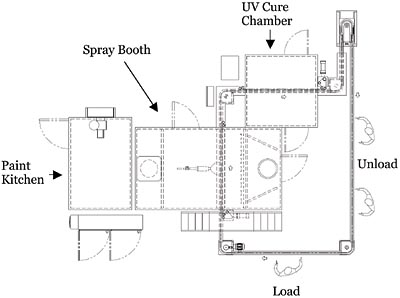

A typical UV-liquid finishing system is depicted in Figure 1 (page 17). The total cycle time is less than four minutes from load to unload. The system consumes approximately 800 square feet of floor space, approximately 10 times less than a typical powder system with the same capacity.

Since installing the new system, Unit Parts has reaped the rewards of adopting 100%-solid UV liquid coatings. Production has more than doubled, paint defects have been reduced from 12% to less than 1/10th of one percent, and VOCs have been dramatically reduced in the painting process. More importantly, Unit Parts is supplying its customers with a superior coated product.

"UV curing is very reliable," Jones says. "We have had excellent results, as far as rejects. The system is very repeatable from hour to hour, day to day, week to week. We can come in on Monday morning after a weekend of being shut down, turn on the system and have it run just as it did on Friday when we shut it off."

Dennis Kaminski is an account manager for Nutro Corp. Reprinted with permission from RadTech International North America, RadTech Report.

Sidebar: Is It Safe?

UV/EB materials are increasingly being used in a wide variety of automotive operations. They typically are much less toxic than some of the ingredients in waterborne or solventborne systems that they replace.They have a very high or no flashpoint, emit little to no VOCs, have very low systemic toxicity, as a class are not carcinogens (recent long-term skin painting tests showed no carcinogenic effect, and the test materials showed no systemic toxicity), and are not fetal or reproductive toxins. Moreover, UV-curing materials are not readily absorbed through the skin like solvents. And since these materials have very low vapor pressures, hazards due to inhalation are less likely.

Nevertheless, as in the case of other types of industrial coatings, certain regulations aimed at assuring worker safety do apply when handling UV/EB materials. Additional specialized requirements apply to automotive OEM and refinish coatings. The following references are recommended for further review:

29 CFR § 1910.1200-Hazard Communication

29 CFR § 1910 Subpart I-Personal Protective Equipment

29 CFR § 1910.134-Respiratory Protection

29 CFR § 1910.123-Dipping and coating operations

29 CFR § 1910.124-General requirements for dipping and coating operations

29 CFR § 1910.125-Additional requirements for dipping and coating operations that use flammable or combustible liquids

29 CFR § 1910.126-Additional requirements for special dipping and coating operations

-Ron Golden, Surface Specialties-UCB, and Martha Marrapese, a partner with the law firm of Keller and Heckmal LLP, from the RadTech Report.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!